Bimetallic catalytic material and preparation method and application method thereof

A technology of catalytic materials and application methods, which is applied in the field of bimetallic catalytic materials and their preparation, can solve the problems of not meeting the needs of wastewater treatment, hindering the application in the environmental field, and high separation costs, so as to achieve rich carbon sources, facilitate recycling, and reuse. The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: A bimetallic catalytic material, including a sponge, on which a catalyst is fixed, the catalyst includes graphene oxide, and the graphene oxide is loaded with nickel metal and cobalt metal.

[0052] The sponge is a melamine sponge.

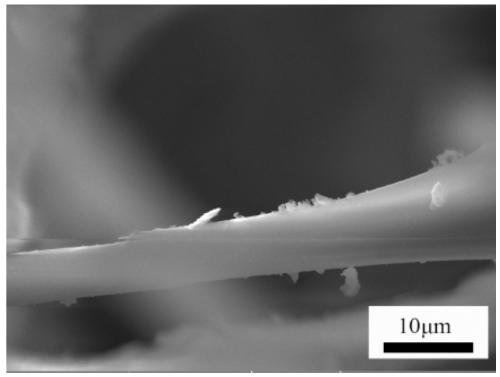

[0053] The SEM characterization picture of the traditional blank sponge is as follows figure 1 As shown, the blank sponge is a smooth continuous network structure; the bimetallic catalytic material of the present application is as figure 2 As shown, the flake structure of bimetallic supported graphene can be seen on the modified sponge framework.

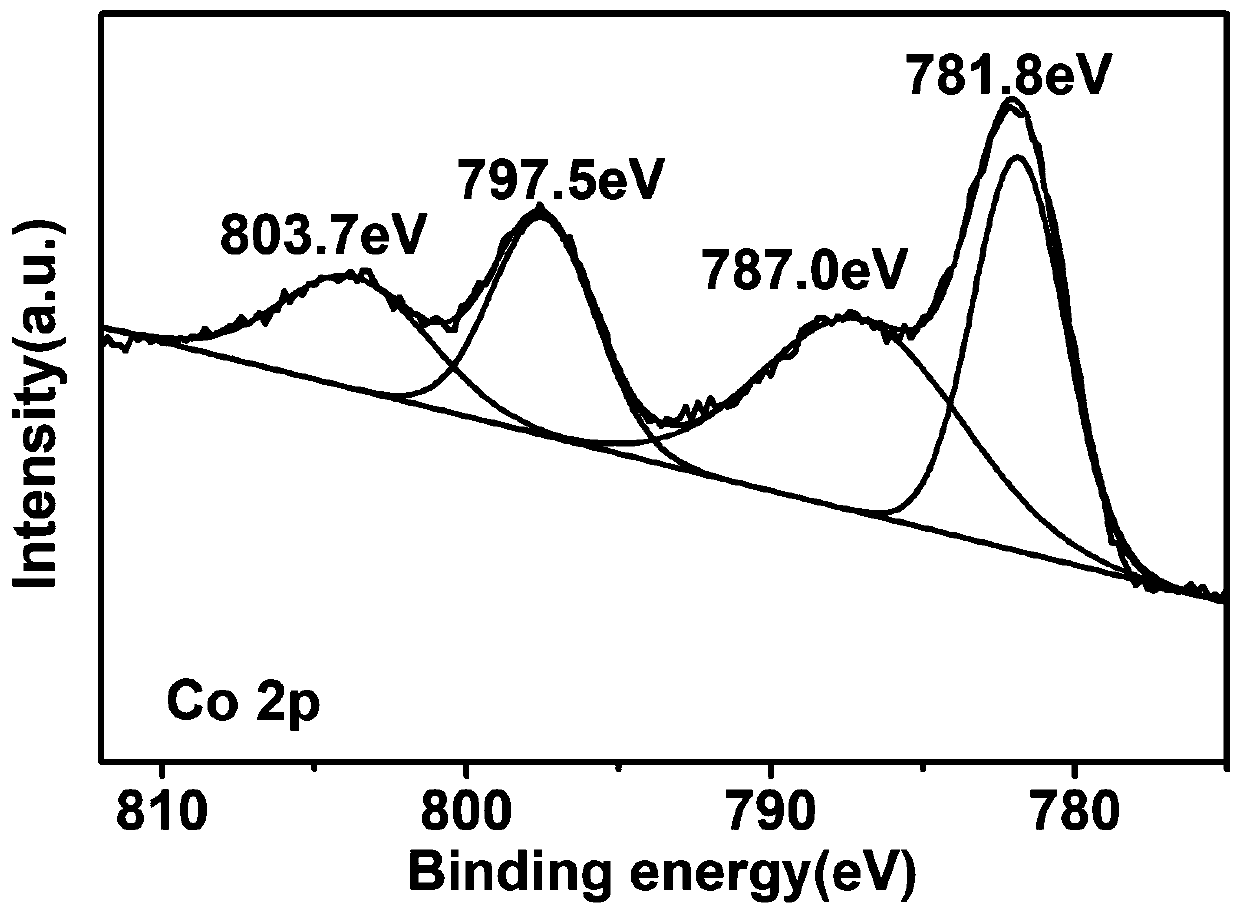

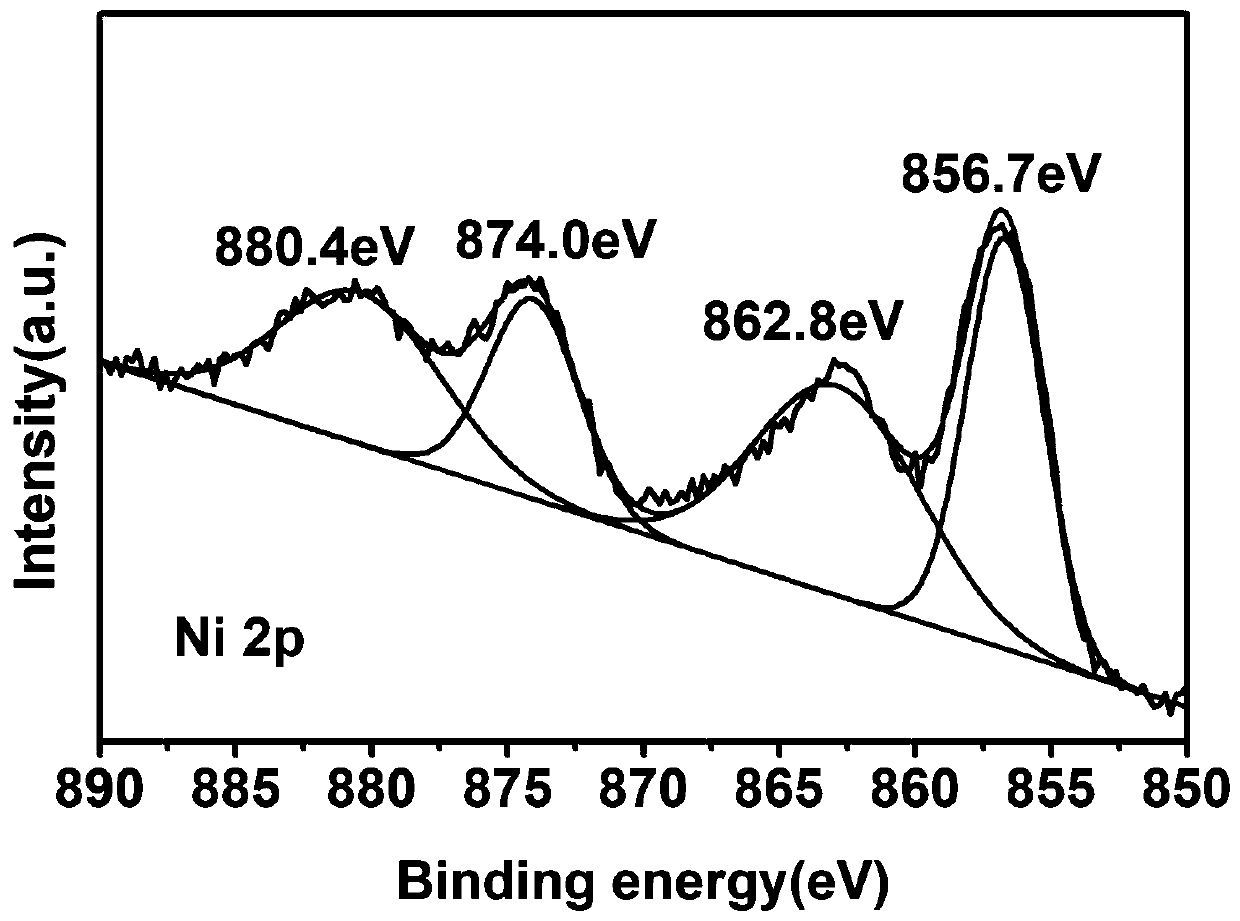

[0054] The surface composition and chemical states of bimetallic catalytic materials were explored using XPS spectra. image 3 is the fitting curve of catalyst Co 2p, the main four peak positions are 803.7eV, 797.5eV, 787.0eV, 781.8eV, which are respectively related to Co 2p 1 / 2 Sat., Co 2p 1 / 2 、Co 2p 3 / 2 Sat., Co 2p 3 / 2 The orbitals are consistent, and its characteristics ar...

Embodiment 2

[0055] Embodiment 2: a kind of preparation method of bimetallic catalytic material, comprises the following steps:

[0056] A, preparation of graphene oxide.

[0057] Graphene oxide was prepared by the Hummers method,

[0058] a1. Add 2 g of graphite powder and 1 g of NaNO3 to 50 mL of concentrated sulfuric acid, and stir mechanically for two hours to obtain solution 1; in addition, the selected concentrated sulfuric acid can be selected within the range of 50-60ml, and the mass ratio of graphite powder and NaNO3 is It is about 2:1, and quantitative errors are allowed.

[0059] a2. Divide 6 g of KMnO4 into 12 times, 0.5g each time, add to solution 1 at an interval of 0.5h, keep stirring, raise the temperature to 35 ℃, and quickly add 80 mL of ultrapure water; in addition, the quality of KMnO4 can be between 4- The range of 8g can be selected, the temperature rise can be selected within the range of 90-98 ℃, and the volume of ultrapure water can be selected within the range of ...

Embodiment 3

[0070] Embodiment 3: a kind of method that bimetallic catalytic material is used for removing phenol, comprises the following steps:

[0071] Step 1: Prepare wastewater.

[0072] Step 2: adding hydrogen peroxide to the waste water. Adjust the pH value of the wastewater to 4.0~9.0. Preferably the pH value of the wastewater is adjusted to 7.0. In addition, potassium persulfate or other persulfates can also be added to the wastewater.

[0073] Step 3: put in the bimetallic catalytic material and start stirring until the waste water is purified.

[0074] This application has done relevant degradation experiments on bimetallic catalytic materials. The degradation experiment of bimetallic catalytic materials adopts a typical research method. Here, bimetallic catalysts are mainly used to activate potassium persulfate (hereinafter referred to as PMS) to degrade phenol. The experimental process for the degradation of phenol with all bimetallic catalysts is as follows: Take 1 mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com