Low-temperature transparent glaze, ceramic product with same and preparation method

A technology of ceramic products and transparent glazes, which is applied in the field of ceramic products, can solve the problems of reduced glaze gloss, high glaze firing temperature, and harmful health of users, and achieve low-temperature transparent glaze uniformity, high gloss, green body uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

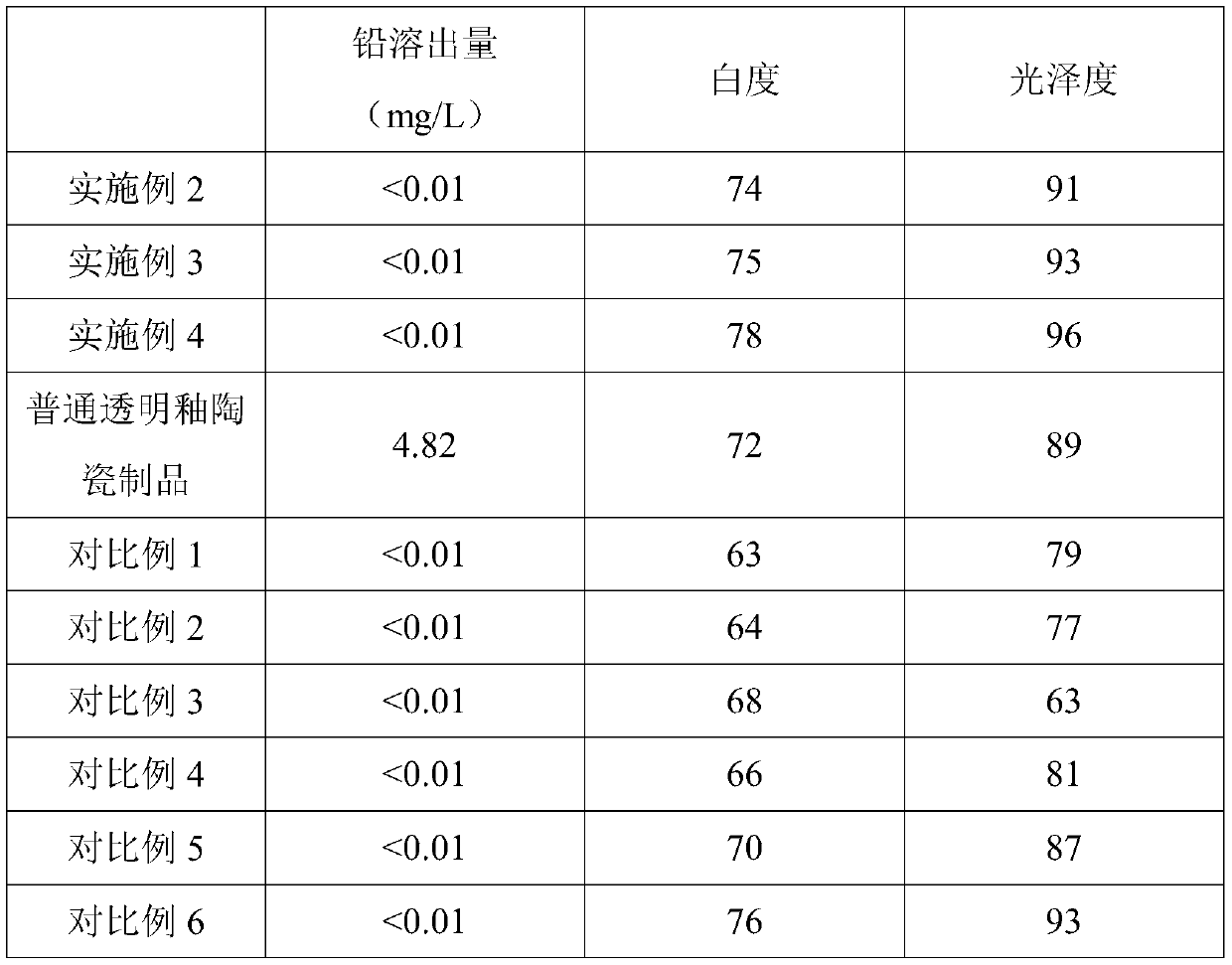

Examples

Embodiment 1

[0032] A low-temperature transparent glaze made from the following raw materials in parts by weight: 28-35 parts of anorthite powder, 20-26 parts of albite powder, 6-10 parts of sericite powder, 15-20 parts of metakaolin, and 11 parts of calcined kaolin ~15 parts, washed soil 4~6 parts, quartz 7~11 parts, high silicon bauxite powder 5~8 parts, titanium oxide 2.5~3.5 parts.

[0033] Preferably, the low-temperature transparent glaze is made of the following raw materials in parts by weight: 32 parts of anorthite powder, 23 parts of albite powder, 8.2 parts of sericite powder, 17.5 parts of metakaolin, 13 parts of calcined kaolin, and 5.5 parts of washed soil , 9.3 parts of quartz, 6.6 parts of high-silicon bauxite powder, and 3 parts of titanium oxide.

[0034] Preferably, the following raw materials are also included in parts by weight: 3-4 parts of rare earth oxides.

[0035] Preferably, the rare earth oxide is a mixture of scandium oxide and terbium oxide with a mass ratio o...

Embodiment 2

[0047] A low-temperature transparent glaze made from the following raw materials in parts by weight: 28 parts of anorthite powder, 20 parts of albite powder, 6 parts of sericite powder, 15 parts of metakaolin, 11 parts of calcined kaolin, 4 parts of washed soil, quartz 7 parts, 5 parts of high-silicon bauxite powder, and 2.5 parts of titanium oxide.

[0048] Preferably, the following raw materials are also included in parts by weight: 3 parts of rare earth oxides.

[0049] Preferably, the rare earth oxide is a mixture of scandium oxide and terbium oxide with a mass ratio of 1:0.7.

[0050] Preferably, the following raw materials are also included in parts by weight: 4 parts of high boron frit.

[0051] Preferably, the aluminum-silicon ratio of the high-silicon bauxite powder is 1:0.21.

[0052] Preferably, the particle size of the anorthite powder, albite powder, sericite powder, metakaolin, washed soil, quartz and high-silicon bauxite powder is not less than 1000 mesh.

[...

Embodiment 3

[0061] A low-temperature transparent glaze made from the following raw materials in parts by weight: 35 parts of anorthite powder, 26 parts of albite powder, 10 parts of sericite powder, 20 parts of metakaolin, 15 parts of calcined kaolin, 6 parts of washed soil, quartz 11 parts, 8 parts of high-silicon bauxite powder, and 3.5 parts of titanium oxide.

[0062] Preferably, the following raw materials are also included in parts by weight: 4 parts of rare earth oxides.

[0063] Preferably, the rare earth oxide is a mixture of scandium oxide and terbium oxide with a mass ratio of 1:0.8.

[0064] Preferably, the following raw materials are also included in parts by weight: 6 parts of high boron frit.

[0065] Preferably, the aluminum-silicon ratio of the high-silicon bauxite powder is 1:0.26.

[0066] Preferably, the particle size of the anorthite powder, albite powder, sericite powder, metakaolin, washed soil, quartz and high-silicon bauxite powder is not less than 1000 mesh.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap