A kind of preparation method of c18-pmh-peg complex

A technology of C18-PMH-PEG and C18-PMH is applied in the field of preparation of C18-PMH-PEG complexes, which can solve the problem of low yield of RGO-IONP-PEG nano-functional complexes and affect the effective modification of RGO-IONP nano-complexes. , the problem of low compound yield, etc., to shorten the process time, avoid the loss of product yield, and achieve the effect of sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

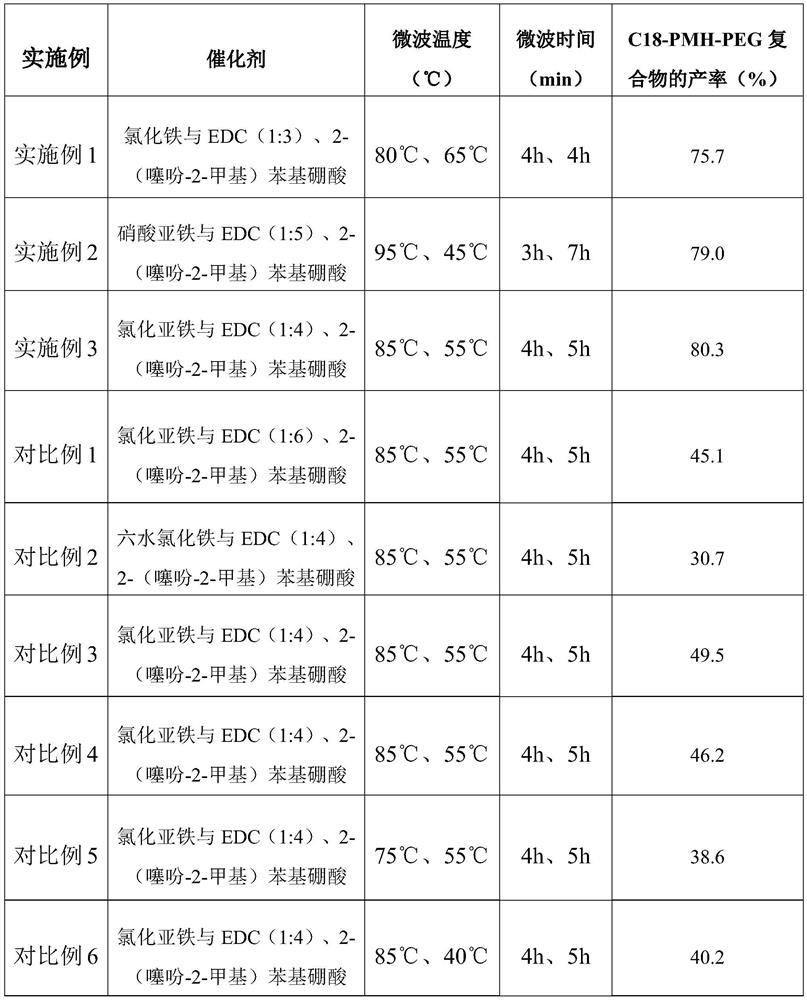

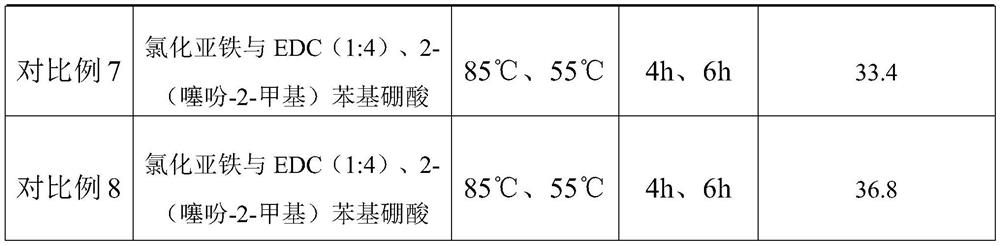

Embodiment 1-

[0023]Example 1-A preparation method of C18-PMH-PEG complex, including the following steps:

[0024](1) Combine 10mg of poly(maleic anhydride-1-octadecene) (C18-PMH) with 143mgNH2-PEG-OCH3(5k) Mix and dissolve in 5ml dichloromethane solution according to the molar ratio of 1:1. First, ferric chloride and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC ) Combined as a catalyst, the mass ratio of ferric chloride to 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) is 1:3, and the dissolving solution is placed at 80 The catalytic reaction is carried out under microwave radiation at ℃, and the reaction time is 4h under microwave radiation to obtain the initial reaction solution; then 2-(thiophen-2-methyl)phenylboronic acid is added as a catalyst, and the catalytic reaction is continued under microwave radiation at 65℃ 4h, get the reaction solution;

[0025]Wherein, the mass ratio of ferric chloride and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochlorid...

Embodiment 2- 1

[0028]Example 2-A preparation method of C18-PMH-PEG complex, including the following steps:

[0029](1) Combine 10mg of poly(maleic anhydride-1-octadecene) (C18-PMH) with 143mgNH2-PEG-OCH3(5k) Mix and dissolve in 5ml dichloromethane solution according to the molar ratio of 1:1, first use ferrous nitrate and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC ) Combined as a catalyst, the mass ratio of ferrous nitrate to 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) is 1:5, and the dissolving solution is placed at 95 The catalytic reaction was carried out under microwave irradiation at ℃, and the reaction time was 3h under microwave irradiation to obtain the initial reaction liquid; then 2-(thiophen-2-methyl)phenylboronic acid was added as a catalyst, and the catalytic reaction was continued under microwave irradiation at 45℃ 7h, get the reaction solution;

[0030]Wherein, the mass ratio of ferrous nitrate and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide h...

Embodiment 3- 1

[0033]Example 3-A preparation method of C18-PMH-PEG complex, including the following steps:

[0034](1) Combine 10mg of poly(maleic anhydride-1-octadecene) (C18-PMH) with 143mgNH2-PEG-OCH3(5k) Mix and dissolve in 5ml dichloromethane solution according to the molar ratio of 1:1, first use ferrous chloride and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride ( EDC) combined as a catalyst, the mass ratio of ferrous chloride to 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) is 1:4, and the solution is placed The catalytic reaction was carried out under microwave irradiation at 85℃, and the reaction time was 4h under microwave irradiation to obtain the initial reaction liquid; then 2-(thiophen-2-methyl)phenylboronic acid was added as a catalyst and continued under microwave irradiation at 55℃ Catalyze the reaction for 5 hours to obtain a reaction liquid;

[0035]Wherein, the mass ratio of ferrous chloride and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com