A kind of antistatic spray-free polypropylene composite material with low linear thermal expansion coefficient and preparation method thereof

A technology of thermal expansion coefficient and composite material, which is applied in the field of antistatic spray-free polypropylene composite material and its preparation, can solve the problems of unqualified appearance of products, restrict the application of spray-free polypropylene composite material, affect the appearance of materials, etc., and improve the surface The effect of antistatic properties, shortening molding cycle, and improving antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

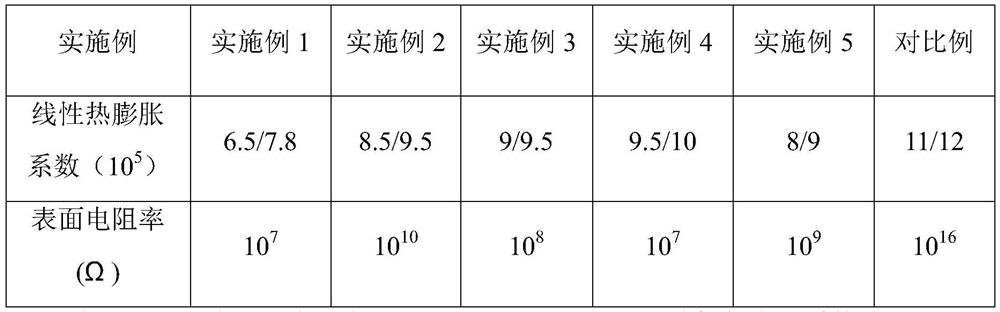

Examples

Embodiment 1

[0035] Weigh 50 parts of dry polypropylene PP-K7926, 20 parts of talcum powder AH51210, 20 parts of toughening agent POE 8200, 0.2 part of metal pigment, 5 parts of functional additives (wollastonite whiskers: ATMER 129 =4:1), 0.1 part of antioxidant 1010, 0.1 part of antioxidant DSTDP, 0.2 part of lubricant EBS, 0.3 part of coupling agent KH550, 0.1 part of light stabilizer V703, add the above materials into a high-speed mixer and mix well , and then put the evenly mixed mixture into the extruder, and cut into pellets after cooling with water. Among them, the processing temperature of the extruder is 180°C, 190°C, 195°C, 195°C, 200°C, 205°C from the feeding port to the die port, the main engine speed is 180rpm, and the vacuum degree is -0.03MPa.

Embodiment 2

[0037] Weigh 70 parts of dry polypropylene PP-K9026, 10 parts of talcum powder AH51210, 15 parts of toughening agent EPDM, 0.4 part of metallic pigment, 1 part of functional auxiliary agent (wollastonite whisker: ATMER 129= 2:1), 0.1 part of antioxidant, 0.1 part of antioxidant DSTDP, 0.2 part of antioxidant 168, 0.2 part of lubricant calcium stearate, 0.3 part of coupling agent KH550, 0.3 part of light stabilizer V703, the above The powder and pellets in the material are added to a high-speed mixer and mixed evenly, and then pelletized after water cooling. Among them, the processing temperature of the extruder is 180°C, 190°C, 195°C, 195°C, 200°C, 205°C from the feeding port to the die port, the speed of the main machine is 200rpm, and the vacuum degree is -0.05MPa.

Embodiment 3

[0039] Weigh 60 parts of dry polypropylene PP-K9026, 34 parts of PP-BX3800, 5 parts of talcum powder AH51210, 9 parts of toughening agent POE 8200, 1 part of metallic pigment, 4 parts of functional additives (silica fume Stone whisker: ATMER 129=1:1), 0.1 part of antioxidant 1010, 0.1 part of antioxidant DSTDP, 0.2 part of antioxidant 168, 0.2 part of lubricant EBS, 0.3 part of coupling agent KH550, 0.3 part of light stabilizer For agent V703, add the above materials into a high-speed mixer and mix them evenly, then add the evenly mixed mixture into the extruder, and cut into pellets after water cooling. Among them, the processing temperature of the extruder is 180°C, 190°C, 195°C, 195°C, 200°C, 205°C from the feeding port to the die port, the main engine speed is 350rpm, and the vacuum degree is -0.05MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com