Oxide thermoelectric material BiCuSeO single crystal and preparation method thereof

A single crystal and crystal growth technology, applied in the field of high-quality oxide thermoelectric material BiCuSeO single crystal and its growth, can solve the problems of low ZT value and low conductivity, and achieve the effects of easy operation, high crystal purity and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

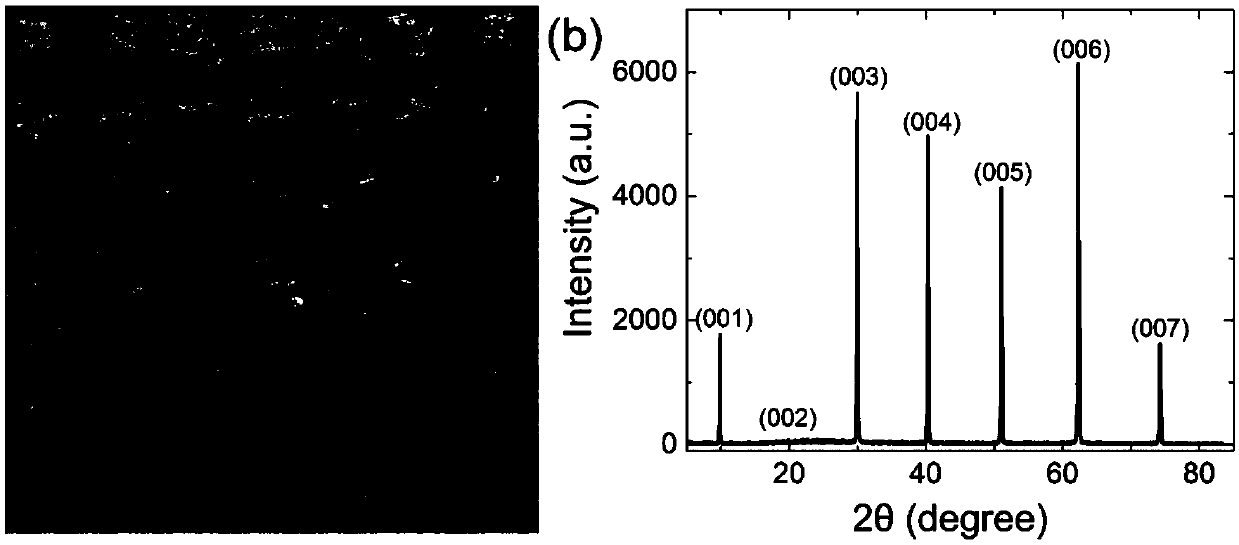

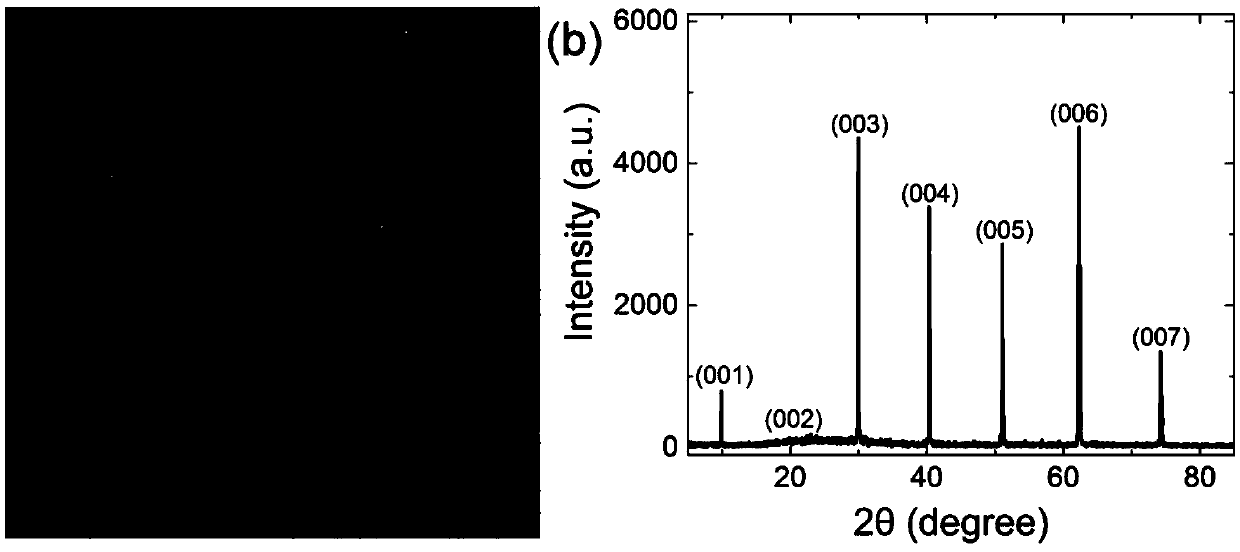

Image

Examples

preparation example Construction

[0036] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0037] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0038] In the experiment, high-purity Bi 2 o 3 , Bi, Cu and Se powders as raw materials, the used transport agent I 2 and Br 2 They are also high-purity reagents, and the quartz tubes for growing crystals are made of high-purity quartz.

Embodiment 1

[0039] Embodiment 1, transport agent is I 2 Growth of BiCuSeO crystals using BiCuSeO powder as raw material under conditions

[0040] Weigh 0.01mol of Bi 2 o 3 powder (4.6595g), 0.01mol of Bi powder (2.0898g), 0.03mol of Cu powder (1.9063g), and 0.03mol of Se powder (2.3688g), mix uniformly and pack into a prepared quartz tube, The mechanical pump and the molecular pump are used to seal the vacuum, and the high-temperature solid-state sintering reaction is carried out at 700 ° C for 5 days to prepare the BiCuSeO polycrystalline powder as the growth raw material. Then weigh about 1.2g of BiCuSeO polycrystalline powder and about 200mg of transport agent I 2 , Grind and mix the two evenly and put them into a prepared quartz tube (length 10cm, diameter 2cm). After the quartz tube is sealed, it is placed in a tube furnace with two temperature zones, and the growth temperature program is set at 500°C (growth end) to 600°C (raw material end). After a 10-day growth cycle, natural ...

Embodiment 2

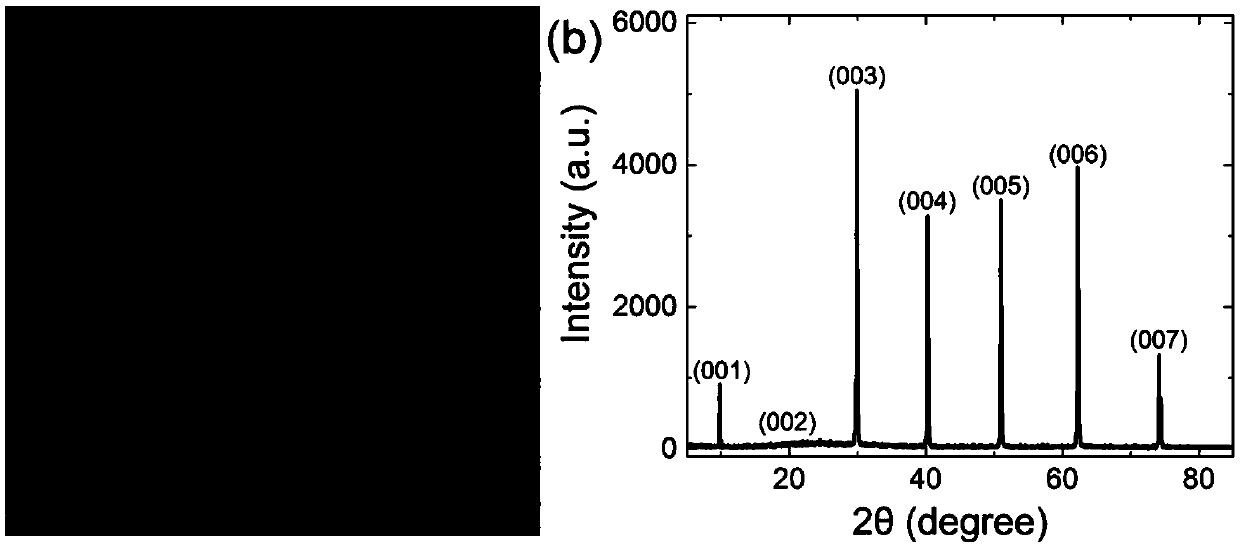

[0042] Embodiment 2, transport agent is I 2 Growth of BiCuSeO crystals using BiCuSeO powder as raw material under conditions

[0043] Weigh 0.01mol of Bi 2 o 3 powder (4.6595g), 0.01mol of Bi powder (2.0898g), 0.03mol of Cu powder (1.9063g), and 0.03mol of Se powder (2.3688g), mix uniformly and pack into a prepared quartz tube, The mechanical pump and the molecular pump are used to seal the vacuum, and the BiCuSeO powder is prepared by performing a high-temperature solid-state sintering reaction at 700 ° C for 5 days as a growth raw material. Then weigh about 1.2g of BiCuSeO powder and about 200mg of transport agent I 2 , Grind and mix the two evenly and put them into a prepared quartz tube (length 10cm, diameter 2cm). After the quartz tube is sealed, it is placed in a tube furnace with two temperature zones, and the growth temperature program is set at 600°C (growth end) to 700°C (raw material end). After a 10-day growth cycle, natural cooling can obtain millimeter-scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com