Method for preparing high-capacity artificial graphite negative electrode material by catalytic graphitization of bulk semi-closed cells

An artificial graphite negative electrode and graphitization technology, applied in chemical instruments and methods, negative electrodes, inorganic chemistry, etc., can solve the problem of uneven catalytic effect, achieve good catalytic effect, good catalytic uniformity, and achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

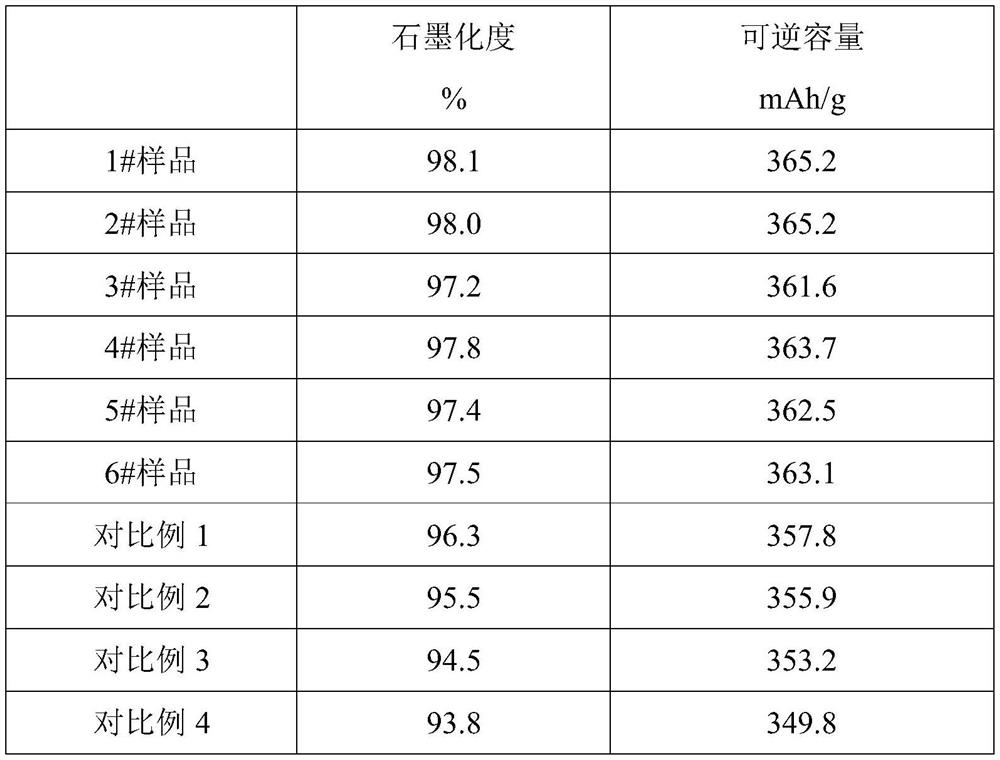

Examples

Embodiment 1

[0052] (1) Mix 8 μm silicon carbide and polypropylene evenly at a mass ratio of 1:2, heat to 150°C while stirring under a nitrogen atmosphere, and spray dry after stirring to obtain a catalyst / pore-forming agent composite with a particle size of 10 μm.

[0053] (2) Mix 8 μm pitch coke with catalyst / pore former compound and coal tar pitch according to the ratio of 10:0.5:1.

[0054] (3) Isostatic pressing: the mixed material is placed in a rubber mold, and isostatically pressed under a pressure of 200 MPa, and the holding time is 2 hours.

[0055] (4) Carbonization: Under a nitrogen atmosphere, the isostatically pressed block material was heated to 750°C at a heating rate of 2°C / min, and a carbon block containing micron-sized pores was obtained after natural cooling.

[0056] (5) Catalytic graphitization: Catalytic graphitization is carried out in a conventional Acheson furnace, the maximum temperature of graphitization is 3000°C, and the temperature is kept for 24 hours.

[0...

Embodiment 2

[0059] (1) Mix 8 μm elemental silicon and polyethylene at a mass ratio of 1:2, heat to 130°C while stirring under a nitrogen atmosphere, and spray dry after stirring to obtain a catalyst / pore-forming agent composite with a particle size of 10 μm.

[0060] (2) Mix 8 μm petroleum coke with catalyst / pore-forming agent compound and coal tar pitch according to the ratio of 10:0.3:0.8.

[0061] (3) Isostatic pressing: the mixed material is placed in a rubber mold, and isostatically pressed under a pressure of 150 MPa, and the holding time is 3 hours.

[0062] (4) Carbonization: Under a nitrogen atmosphere, the isostatically pressed block was heated to 700°C at a heating rate of 1°C / min, and a carbon block containing micron-sized pores was obtained after natural cooling.

[0063] (5) Catalytic graphitization: Catalytic graphitization is carried out in a conventional Acheson furnace, the maximum temperature of graphitization is 3000°C, and the temperature is kept for 24 hours.

[006...

Embodiment 3

[0066] (1) Mix 8 μm silica and polystyrene evenly at a mass ratio of 1:0.5, heat to 180°C while stirring under a nitrogen atmosphere, and spray dry after stirring to obtain a catalyst / pore-forming agent composite with a particle size of 15 μm .

[0067] (2) Mix 5 μm petroleum coke with catalyst / pore-forming agent compound and coal tar pitch according to the ratio of 10:1:1.5.

[0068] (3) Isostatic pressing: the mixed material is placed in a rubber mold, and isostatically pressed under a pressure of 250MPa, and the holding time is 1h.

[0069] (4) Carbonization: In a helium atmosphere, the isostatically pressed block material was heated to 850°C at a heating rate of 5°C / min, and a carbon block containing micron-sized pores was obtained after natural cooling.

[0070] (5) Catalytic graphitization: Catalytic graphitization is carried out in a conventional Acheson furnace, the maximum temperature of graphitization is 3000°C, and the temperature is kept for 24 hours.

[0071] (6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com