Multilayer carbon nanotubes, method for producing multilayer carbon nanotubes, liquid dispersion, resin composition, and coating film

A technology of multi-layer carbon nanotubes and manufacturing methods, applied in the direction of multi-walled carbon nanotubes, carbon nanotubes, nanocarbons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0193] Examples are given below to describe the present invention more specifically. The present invention is not limited to the following examples unless the gist is exceeded. In Examples, unless otherwise specified, "part" means "mass part", and "%" means "mass %". In addition, "carbon nanotube" may be abbreviated as "CNT" and "carbon black" may be abbreviated as "CB".

[0194]

[0195] The physical properties of CNTs or CNT coating films used in Examples and Comparative Examples described later were measured by the following methods.

[0196]

[0197] CNTs were installed in a Raman microscope (XploRA, manufactured by Horiba, Ltd.), and measurements were performed using a laser wavelength of 532 nm. The measurement conditions were as follows: acquisition time 60 seconds, integration times 2, light reduction filter 10%, objective lens magnification 20 times, diffraction grating number of lines 1200 / min, total aperture 500, slit width 100 μm. The CNTs for measurement we...

no. 1 example

[0210]

[0211] The catalyst for CNT synthesis used in each of the Examples and Comparative Examples described below was produced by the following method.

[0212] Catalyst for CNT Synthesis (A)

[0213] Weigh 60 parts of cobalt hydroxide, 138 parts of magnesium acetate tetrahydrate, and 16.2 parts of manganese acetate into a heat-resistant container, and use an electric oven to dry at a temperature of 170±5°C for 1 hour to evaporate the water, then use With a pulverizer (Wonder Mill WC-3, manufactured by Osaka Chemical Co., Ltd.), the speed (SPEED) dial was adjusted to 3, and pulverized for 1 hour. Then, for each pulverized powder, use a pulverizer (Wonder Mill WC-3, manufactured by Osaka Chemical Co., Ltd.), adjust the speed dial to 2, and mix for 30 seconds to prepare a catalyst precursor for CNT synthesis (A ). Furthermore, the catalyst precursor (A) for CNT synthesis was transferred to a heat-resistant container, and calcined in an air atmosphere at 450±5° C. for 30 m...

Embodiment 1

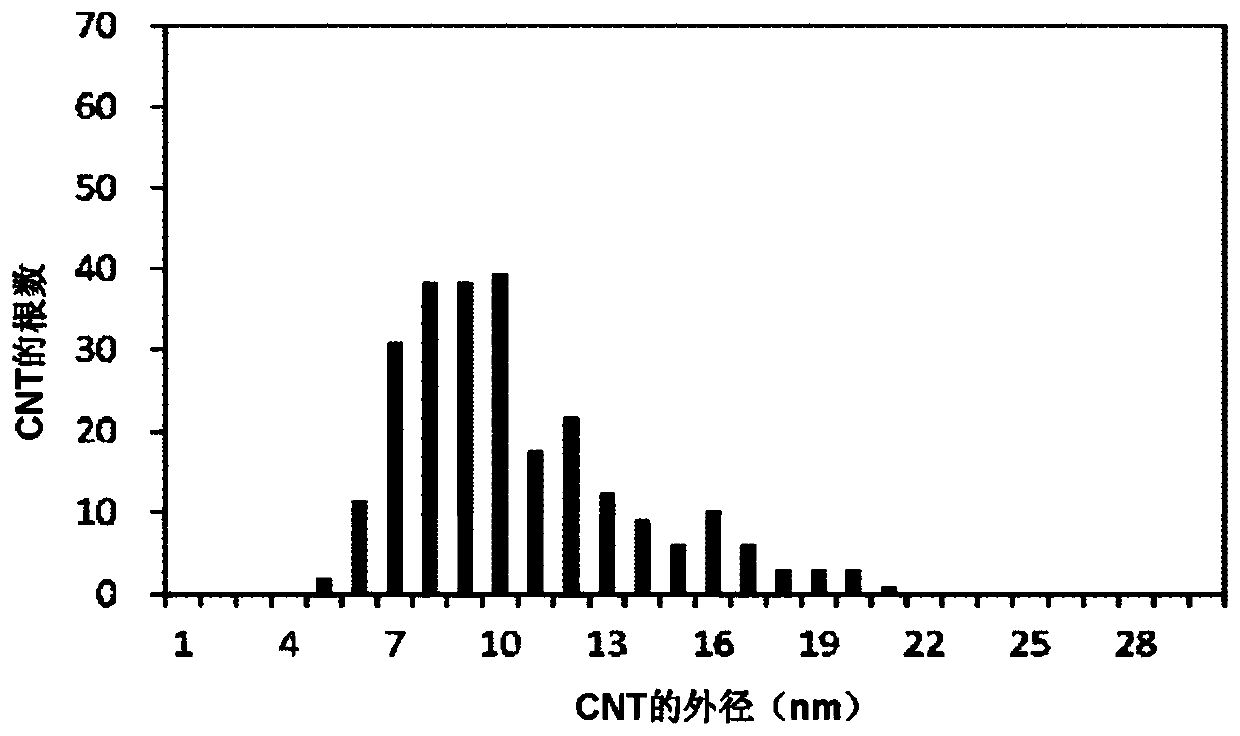

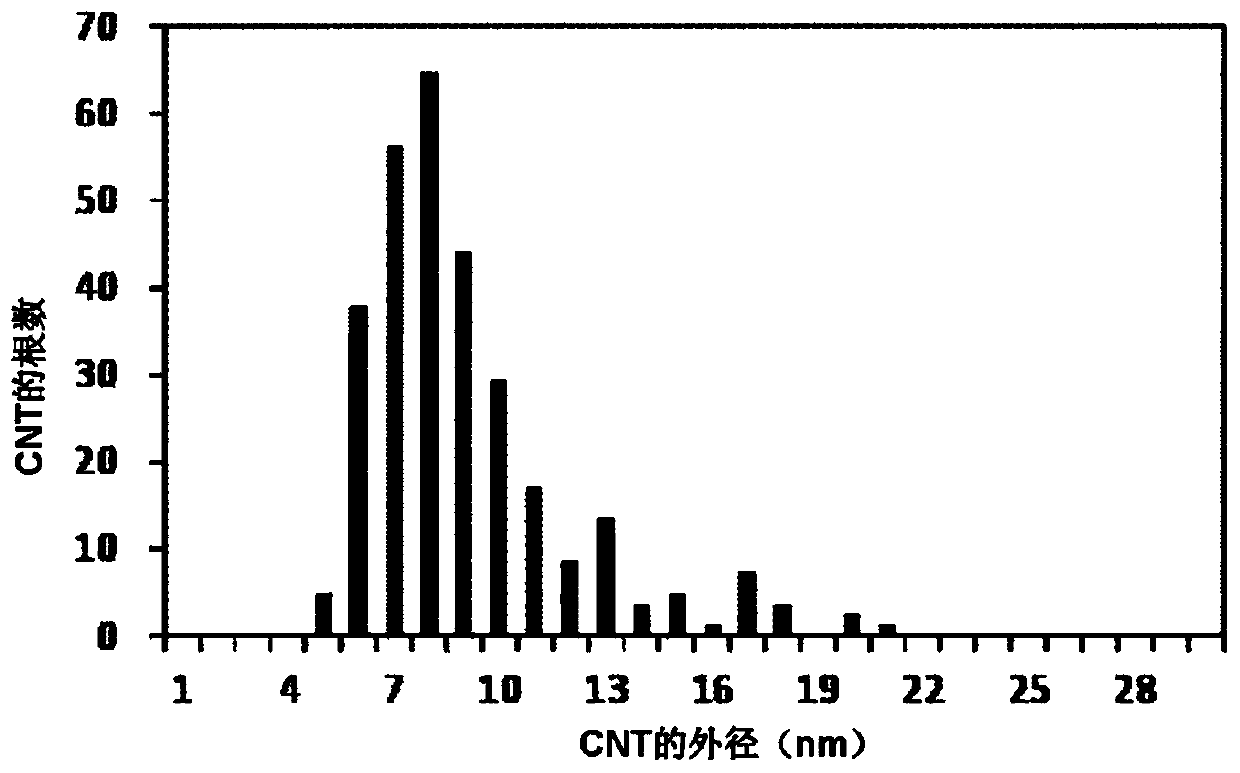

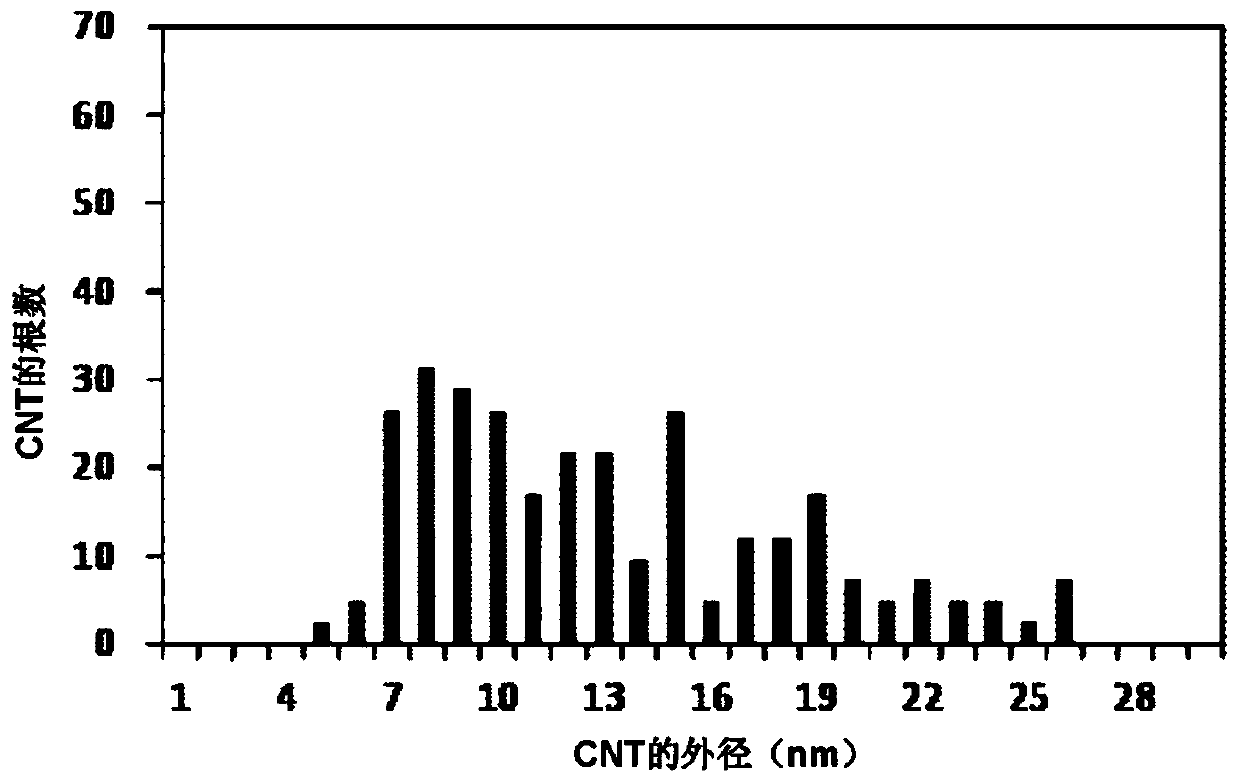

[0224] (Example 1) Production of CNT (A)

[0225] In the center of a horizontal reaction tube with an internal volume of 10 L that can be pressurized and heated by an external heater, a quartz glass heat-resistant dish on which 2.0 g of the catalyst for CNT synthesis (A) was scattered was installed. Exhaust was performed while injecting nitrogen gas, and the air in the reaction tube was replaced with nitrogen gas so that the atmosphere in the horizontal reaction tube had an oxygen concentration of 1% by volume or less. Next, heating was performed with an external heater until the center temperature in the horizontal reaction tube became 680°C. After reaching 680° C., propane gas was introduced into the reaction tube as a carbon source at a flow rate of 2 L per minute, and a contact reaction was performed for 1 hour. After the reaction, the gas in the reaction tube was substituted with nitrogen, and the temperature of the reaction tube was cooled to 100° C. or lower, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com