Negative electrode active material, mixed negative electrode active material material and preparation method of negative electrode active material

A negative electrode active material and carbon material technology, which is applied in the direction of active material electrodes, negative electrodes, battery electrodes, etc., can solve the problems of electrolyte consumption and easy degradation of battery cycle characteristics, and achieve high-capacity cycle characteristics and good cycle characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0125] Make the following steps figure 2 A laminated film type lithium ion secondary battery 20 is shown.

[0126] The positive electrode was initially made. Mixed positive electrode active material, namely LiNi as lithium nickel cobalt composite oxide 0.7 Co 0.25 Al 0.05 O (lithium nickel cobalt aluminum composite oxide: NCA) 95 mass %, positive electrode conductive aid 2.5 mass %, positive electrode binder (polyvinylidene fluoride: PVDF) 2.5 weight %, and the positive electrode mixture was prepared. Next, the positive electrode mixture was dispersed in an organic solvent (N-methyl-2-pyrrolidone: NMP) to prepare a paste-like slurry. Next, the slurry was applied to both surfaces of the positive electrode current collector by using a coating device having a die, and was dried by a hot-air drying device. At this time, a positive electrode current collector with a thickness of 15 μm was used. Finally, compression molding is performed using a roll press.

[0127] Subsequen...

Embodiment 1-2

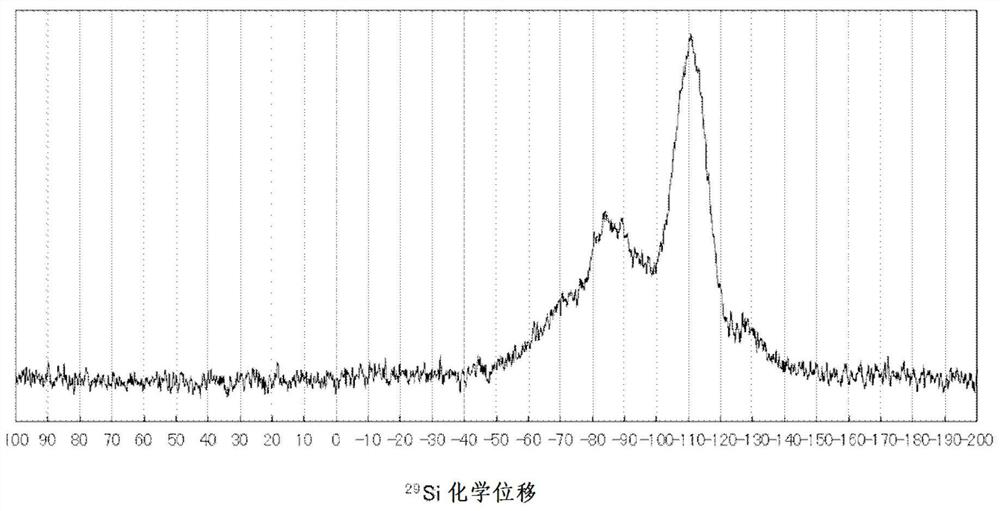

[0144] The second step was carried out in the same manner as in Example 1-1, except that the temperature of the precipitation chamber was set to 750° C., the degree of vacuum was set to 0.3 Pa, and the film-forming rate of the silicon compound film on the adsorption plate was set to 15 g per hour. The battery was manufactured, and the cycle retention rate was calculated. As described above, in Example 1-2, by changing the temperature of the precipitation chamber, the degree of vacuum, and the film formation rate, the crystallinity of the silicon compound particles was changed, so that the 29 The shape of the Si-MAS-NMR spectrum changes.

[0145] Here, the silicon compound particles prepared in Example 1-2 were 29 The Si-MAS-NMR spectrum is shown in Figure 4 . of the silicon compound particles in Examples 1-2 29 In the Si-MAS-NMR spectrum, the following peaks appeared, respectively: -70 ppm peak derived from Si region with long period regularity; -80 ppm peak derived from ...

Embodiment 2-1~2-2 and comparative example 2-1、2-2

[0164] Production of a secondary battery was carried out in the same manner as in Example 1-1, except that the amount of oxygen in the silicon compound bulk was adjusted. At this time, the amount of oxygen is adjusted by changing the ratio of metal silicon to silicon dioxide in the raw material of the silicon compound and the heating temperature. Table 2 shows the SiO in Examples 2-1, 2-2 and Comparative Examples 2-1, 2-2 x The x-value of the silicon compound represented.

[0165] [Table 2]

[0166] SiOx D 50 =8μm, graphite (natural graphite:artificial graphite=5:5) D 50 =20μm

[0167] SiOx ratio 10% by mass, carbon material average thickness 50nm

[0168] Half-value width 2.257°, crystallite 3.77nm

[0169]

[0170] As shown in Table 2, in SiO x In the represented silicon compound, when the value of x is outside the range of 0.5≤x≤1.6, the battery characteristics deteriorate. For example, as shown in Comparative Example 2-1, when oxygen was insufficient (x=0.3), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com