Coal gangue based geopolymer and preparation method thereof

A coal gangue and polymer technology, applied in the field of building materials, can solve the problems of poor utilization of industrial solid waste and low compressive strength of geopolymers, and achieve the effects of excellent durability, high mechanical strength and low permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

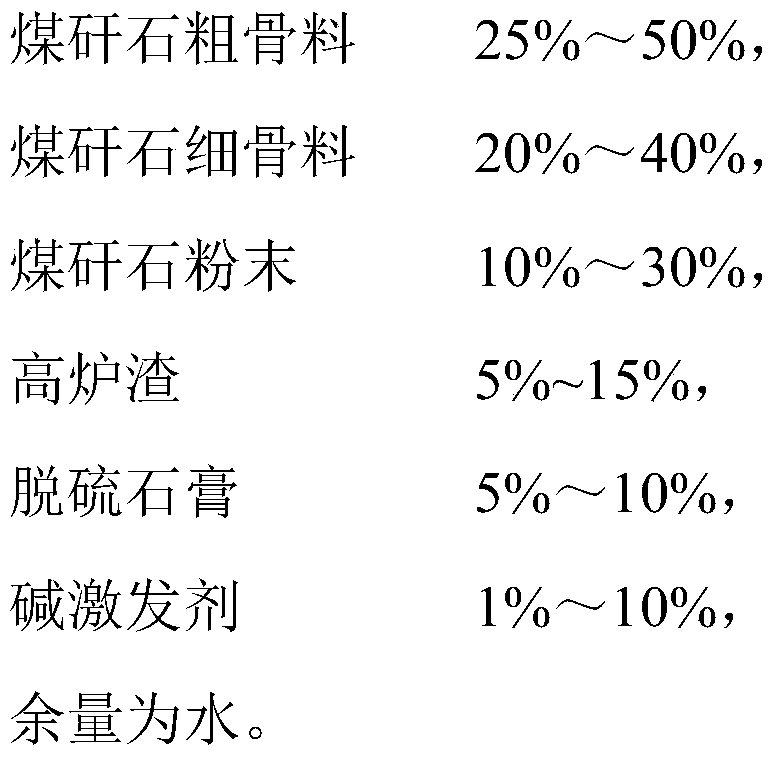

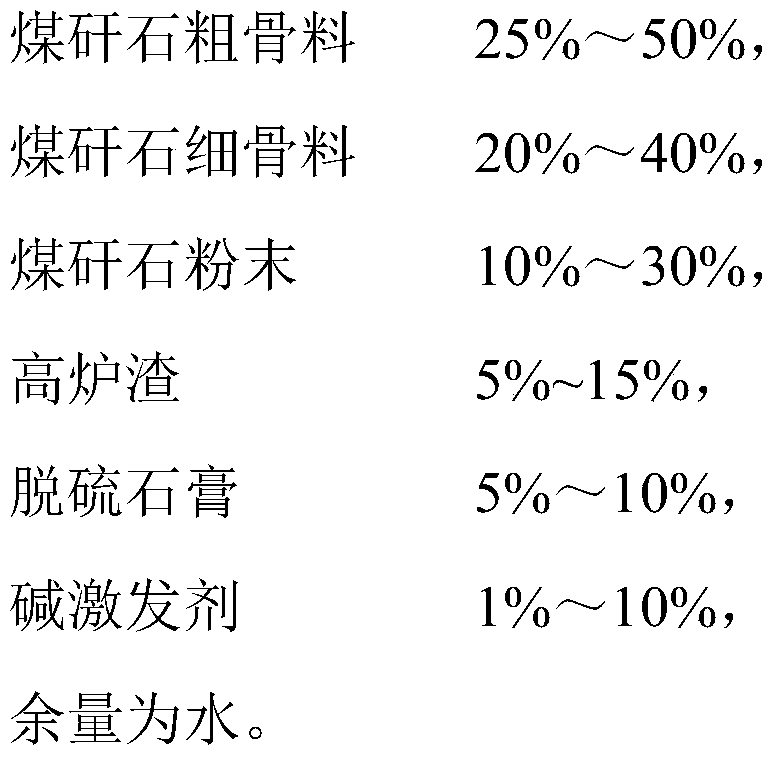

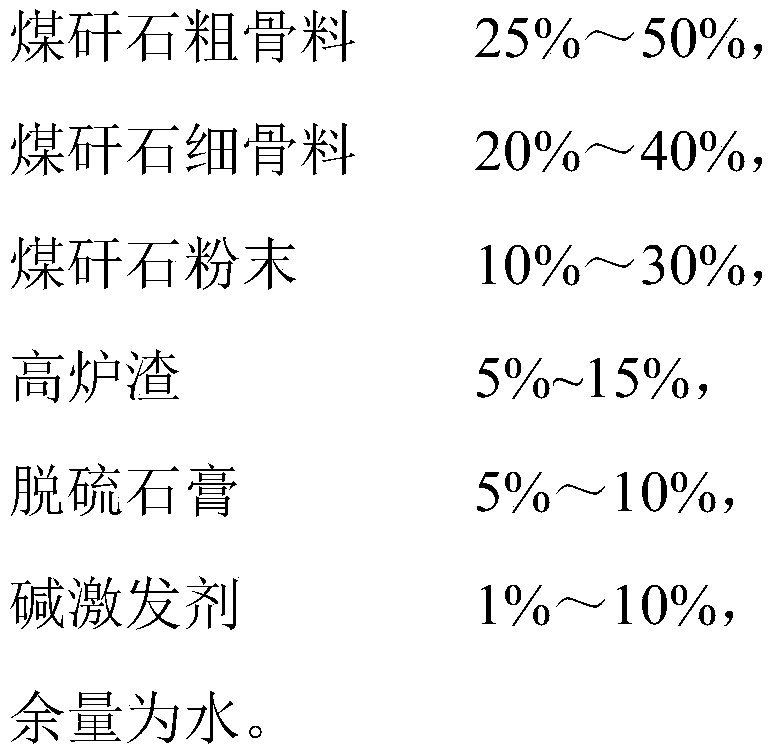

[0051] The embodiment of the present invention also provides a method for preparing a coal gangue-based geopolymer, comprising the following preparation steps:

[0052] S10. Obtain coal gangue coarse aggregate, coal gangue fine aggregate, coal gangue powder, blast furnace slag, and desulfurized gypsum, and combine the coal gangue coarse aggregate, the coal gangue fine aggregate, the coal gangue powder, the The blast furnace slag is mixed with the desulfurized gypsum to obtain a mixture;

[0053] S20. Obtain a base activator, and dissolve the base activator in water to obtain an aqueous solution of the base activator;

[0054] S30. Adding the aqueous solution of the alkali activator to the mixture for mixed treatment to obtain a coal gangue-based geopolymer slurry;

[0055] S40. Putting the geopolymer slurry into a mold for curing to obtain a coal gangue-based geopolymer.

[0056] The preparation method of the coal gangue-based geopolymer provided by the embodiment of the pre...

Embodiment 1

[0069] A coal gangue-based geopolymer, comprising the steps of:

[0070] ①Put 7kg of desulfurized gypsum, 15kg of coal gangue powder, 8kg of blast furnace slag, 30kg of coal gangue coarse aggregate, and 20kg of coal gangue fine aggregate into a stirrer and mix evenly to obtain a mixture.

[0071] ②Dissolve 3kg of powdered sodium silicate and 2kg of sodium hydroxide in 15kg of water, and fully stir to dissolve to obtain an aqueous solution of alkali activator.

[0072] ③The aqueous alkali activator solution was poured into the stirrer containing the mixture, fully stirred and mixed for 5 minutes, and the coal gangue-based geopolymer slurry was obtained.

[0073] ④ Pour the gangue-based geopolymer slurry into the abrasive tool, and place the abrasive tool with the material on a flat vibrator to vibrate for 5 minutes. Put the mold into the curing box to cure the gangue geopolymer under the curing conditions of temperature 30° C. and humidity 90% to obtain the gangue-based geopol...

Embodiment 2

[0075] A coal gangue-based geopolymer, comprising the steps of:

[0076] ①Put 5kg of desulfurized gypsum, 20kg of coal gangue powder, 10kg of blast furnace slag, 25kg of coal gangue coarse aggregate, and 25kg of coal gangue fine aggregate into a mixer and stir to mix evenly to obtain a mixture.

[0077] ②Dissolve 2kg of powdered sodium silicate and 1kg of sodium hydroxide in 12kg of water, and fully stir to dissolve to obtain an aqueous solution of alkali activator.

[0078] ③The aqueous alkali activator solution was poured into a stirrer filled with the mixture, fully stirred and mixed for 5 minutes, and the coal gangue-based geopolymer slurry was obtained.

[0079] ④ Pour the gangue-based geopolymer slurry into the abrasive tool, and place the abrasive tool with the material on a flat vibrator to vibrate for 5 minutes. Put the mold into the curing box to cure the gangue geopolymer under the curing conditions of temperature 20° C. and humidity 90%, to obtain the gangue-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com