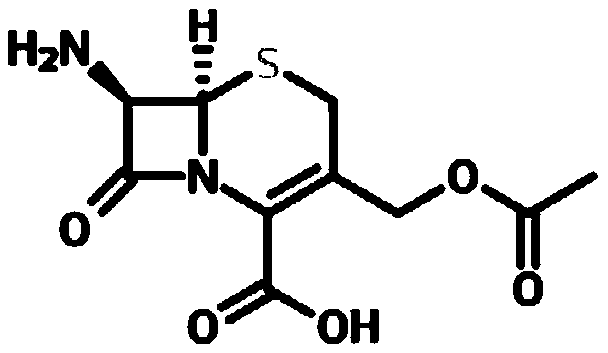

Preparation method of cephalosporin C sodium salt and 7-amino-cephalosporanic acid

A technology of amino cephalosporanic acid and cephalosporin, which is applied in the field of preparation of cephalosporin C sodium salt and 7-amino cephalosporanic acid, can solve the problem of inability to perform ultrafiltration, waste acid water and resin regeneration waste liquid, easy blockage Membrane holes and other problems, to meet the needs of high-end customers, high product quality, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In the preparation method of cephalosporin C sodium salt provided by the present invention, in the preparation of said step (1) containing cephalosporin C filtrate, after cephalosporin C fermented liquid is acidified, adopt 50~100 nanometer ceramic Membrane filtration removes mycelium and protein in the fermentation broth, and then adopts an ultrafiltration membrane with a molecular weight cut-off of 20KD to 100KD to remove pigment and impurities in the filtrate to obtain a cephalosporin C-containing filtrate.

[0022] Wherein, the cephalosporin C fermentation liquid is the fermentation liquid prepared by the conventional biological fermentation method in the field after the biological fermentation of cephalosporin C, the general pH is 4.50-6.00, and the supernatant contains about 20g / L-30g / L cephalosporin Factor C, the fermentation broth also contains a large amount of mycelium, protein, polysaccharide, colloid and so on.

[0023] The acidification treatment of the cep...

Embodiment 1

[0037] Get 4.5L cephalosporin C fermented liquid, pH is 4.65, contains about 22g / L cephalosporin C (supernatant liquid), uses the sulfuric acid of 15% (v / v) to adjust pH to 2.50, then at 5 ℃~10 Under the condition of ℃, after filtering through 50nm ceramic membrane and 20KD ultrafiltration membrane, 5.2L filtrate (including ceramic membrane top wash water) was obtained, the concentration of cephalosporin C was 7.50g / L, and the light transmittance at 425nm wavelength was 72%.

[0038] Add 15.6L of ethyl acetate pre-cooled to 5-10°C to the filtrate, mix thoroughly, and collect 15.0L of the light phase after standing and layering, the concentration of cephalosporin C is 2.52g / L; then, at about 5°C, add 83mL of 20wt% sodium isooctanoate ethyl acetate solution to the collected light phase at a uniform speed within 15min, let it stand for 20min after the addition, separate layers, collect 175mL of the heavy phase, and the concentration of cephalosporin C is 211.8 g / L; at 5°C, 175ml...

Embodiment 2

[0041] Get 4.5L cephalosporin C fermented liquid, pH is 4.72, contains about 23g / L cephalosporin C (supernatant liquid), uses the sulfuric acid of 15% (v / v) to adjust pH to 2.56, then at 5 ℃~10 Under the condition of ℃, after filtering through 50nm ceramic membrane and 20KD ultrafiltration membrane, 5.4L filtrate (including ceramic membrane top wash water) was obtained, the concentration of cephalosporin C was 7.32g / L, and the light transmittance at 425nm wavelength was 76%.

[0042] Add 16.2L of ethyl acetate pre-cooled to 5-10°C to the filtrate, mix thoroughly, and collect 15.7L of the light phase after standing and layering, the concentration of cephalosporin C is 2.43g / L; then, at about 5°C, add 84mL of 20wt% ethyl acetate solution of sodium isooctanoate dropwise to the collected light phase at a uniform speed within 15min, let it stand for 20min after the addition, separate the layers, collect 195mL of the heavy phase, and the concentration of cephalosporin C is 193.0 g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com