Water-expandable flexible flame-retardant foam plastic and preparation method thereof

A foam plastic and water-swelling technology, which is applied in the field of polyurethane foam plastics, can solve the problems of water retention performance decline, low water absorption expansion rate, flammability and non-self-extinguishing, etc., to achieve enhanced water retention capacity, stable water absorption performance, and physical and mechanical properties. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

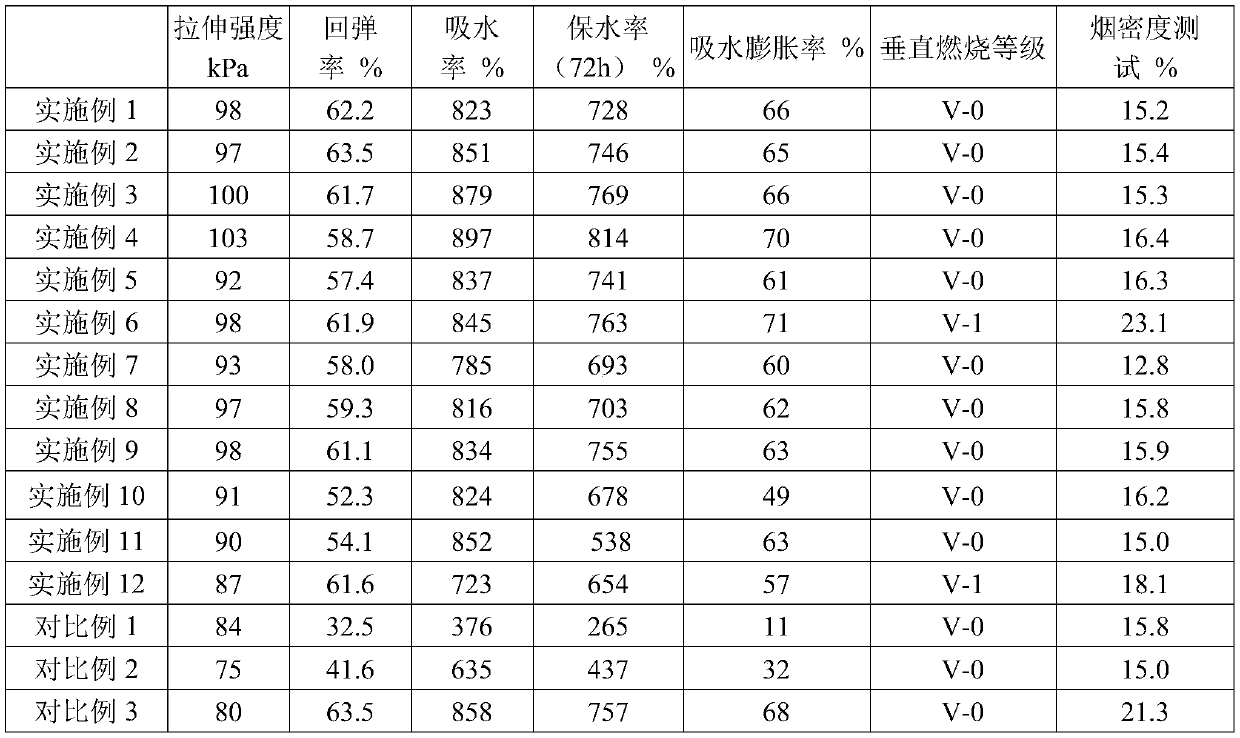

Examples

preparation example 1

[0047] Preparation example 1 polyvinyl alcohol / isocyanate silane coupling agent graft copolymer

[0048] Add 106.6g of polyvinyl alcohol with a molecular weight of 25,000 and an alcoholysis degree of 70% to the reaction kettle, vacuum dehydrate it at 20°C for 2 hours, cool down the polyvinyl alcohol to 60°C, and add the polyvinyl alcohol that has been preheated at 60°C to the above system Prepare 40g of 3-isocyanatopropyltrimethoxysilane, 200g of DMSO, fully react at 60°C for 4 hours under temperature control, vacuum filter and dry to obtain the grafted crude product, and extract the crude product with acetone for 48 hours to remove unreacted small molecules , the insoluble matter was dried in a vacuum oven at 60° C. to a constant weight of 130 g to obtain a polyvinyl alcohol / isocyanate silane coupling agent graft copolymer with a graft rate of 18%.

[0049] According to the similar method, the ratio of raw materials and the reaction time can be adjusted to obtain different ...

preparation example 2

[0050] Preparation Example 2 Preparation of Modified Flame Retardant

[0051] The preparation method of modified flame retardant comprises the steps:

[0052] 1) Put 20 parts of aluminum hydroxide into a drying oven, dry at 120°C for 3 hours, and cool the dried flame retardant to room temperature for later use;

[0053] 2) Weigh the aluminum hydroxide obtained in step 1) and add it to a high-speed mixer, keep the temperature at 60°C, continue stirring, spray 1.5% 4,4'-diphenylmethane diisocyanate on the flame retardant, and stop after 10 minutes Stir and heat to obtain the modified flame retardant.

Embodiment 1

[0054] Example 1 Preparation of water-swellable flexible flame-retardant foam

[0055] A water-swellable flexible foam plastics, comprising the following raw materials in parts by weight: 40 parts of polyethylene oxide glycerol with an average relative molecular weight of 5500, 5 parts of polyvinyl alcohol / silane coupling agent graft copolymer, 60 parts of toluene -2,4-diisocyanate, 3 parts of Momentive L-6188 cell opener, 1 part of Momentive silicone oil L580 foam stabilizer, 15 parts of compound foaming agent composed of water and pentane, wherein the mixture of water and pentane The ratio is 6:1, 20 parts of 3-isocyanate propyltriethoxysilane modified aluminum hydroxide, 3 parts of dibutyltin dilaurate.

[0056] The preparation steps are:

[0057] 1) Add Momentive silicone oil L580 foam stabilizer, Momentive L-6188 cell opener, and 3-isocyanate propyltriethoxysilane modified aluminum hydroxide in the above raw materials into the high-speed mixer, and mix until Uniform; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com