Method for preparing nano dispersion strengthened alloy

A technology of dispersion strengthening and alloying, which is applied in the field of preparation of nano-dispersion strengthening alloys. It can solve the problems that the properties of alloys are difficult to meet engineering applications, the difficulty of adding nanoparticles, and the dispersion of particles are difficult to achieve, so as to reduce the floating and sinking speed of particles and reduce the cost. , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

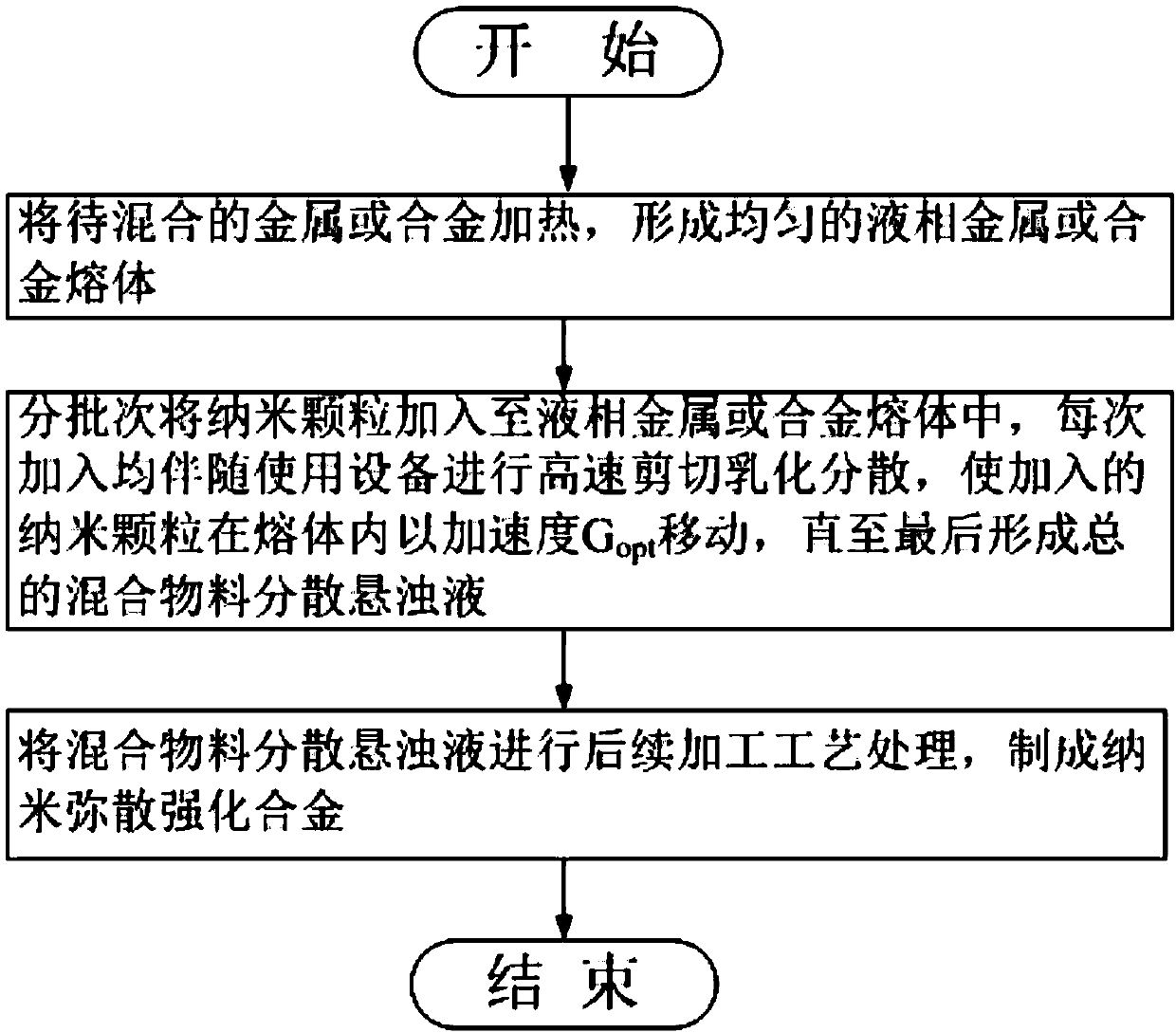

[0025] Such as figure 1 As shown, the present invention provides a preparation method of nano-dispersion strengthened alloy, comprising the following steps: heating the metal or alloy to be mixed to form a uniform liquid phase metal or alloy melt; adding nanoparticles to the In the liquid phase metal or alloy melt, each addition is accompanied by emulsification equipment for high-speed shear stirring, so that the moving acceleration of the added nanoparticles reaches G opt , until a uniformly dispersed emulsified suspension is finally formed; the suspension is subjected to subsequent processing to make a nano-dispersion strengthened alloy.

[0026] In the above steps, the size of the added nanoparticles is 1-100nm, in some embodiments, specifically 1nm, 10nm, 20nm, 30nm, 40nm, 50nm, 60nm, 70nm, 80nm, 90nm and 100nm.

[0027] In the above steps, high-speed shear emulsification and dispersion make the final acceleration of the mixed material 30-100G, specifically 30G, 40G, 50G,...

Embodiment 1

[0034] Put 3kg of pure metal copper ingot in a graphite melting furnace and heat it to 1200°C under the protection of nitrogen atmosphere; after the copper ingot is completely melted, add 3g of nano-alumina particles with a particle size of 100nm; Insert the emulsification head into the copper liquid, turn it on and gradually increase the speed to a line speed of 60m / s; after 30 minutes of high-speed shear emulsification and dispersion, add 3g of nano-alumina particles again, and high-speed shear emulsification for 30 minutes again, repeat this process, Up to a total of 30g of nano-alumina particles were added to form a suspension of nano-alumina particles-copper melt; the suspension of nano-alumina particles-copper melt was poured into a mold, and cooled by circulating water for 20 minutes to obtain nano Alumina dispersion strengthened copper castings.

[0035] The prepared nano-alumina dispersion-strengthened copper castings were tested for particle distribution and performa...

Embodiment 2

[0037] Put 2kg of Fe-Cr alloy ingot (Fe-Cr12wt%) in graphite smelting furnace and heat it to 1500°C under the protection of argon atmosphere; after the alloy ingot is completely melted, add 10g of nanometer yttrium oxide particles with a particle size of 80nm; The emulsification head of the high-speed shear emulsification disperser extends into the tin liquid, opens and gradually increases the speed to a line speed of 40m / s; after 20 minutes of high-speed shear emulsification and dispersion, the nano-yttrium oxide particles-iron-chromium alloy melt is suspended The solution was poured into the mold and cooled rapidly by circulating water for 15 minutes to obtain nano-yttrium oxide dispersion-strengthened iron-chromium alloy castings.

[0038] The obtained nano-yttrium oxide dispersion-strengthened iron-chromium alloy castings were tested for particle distribution and performance. The results showed that in the prepared nano-yttrium oxide dispersion-strengthened iron-chromium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com