A kind of preparation method of fiber softening type betel nut prolonging shelf life

A fiber softening and production method technology, applied in the field of edible betel nut processing, can solve problems such as poor chewing taste, irritation of oral mucosa, loss of flavor, etc., and achieve the effects of reducing the probability of contact, good chewing taste, and improving the juice feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

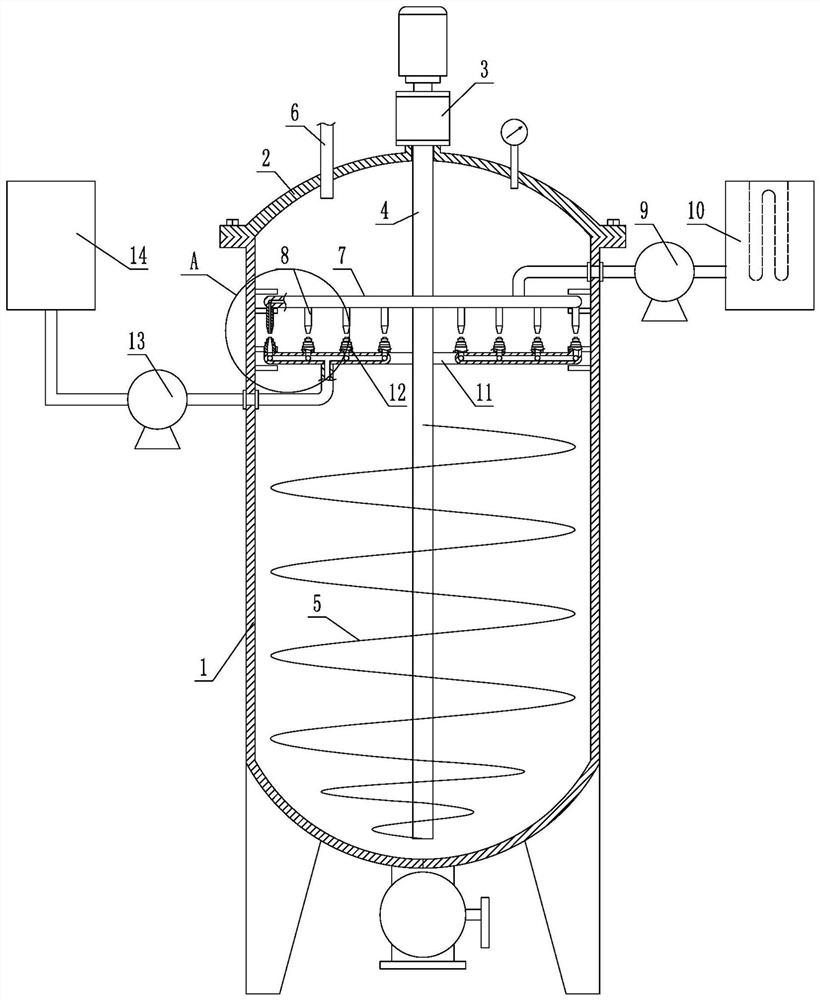

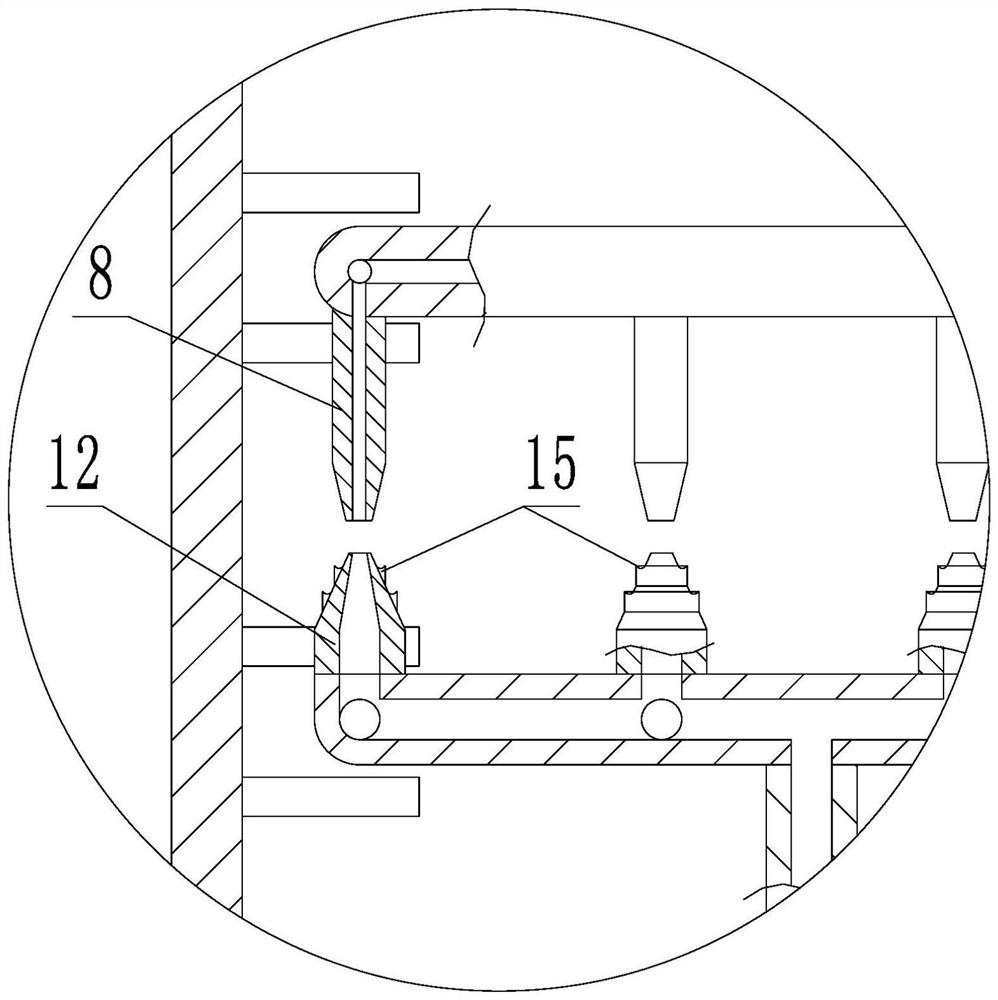

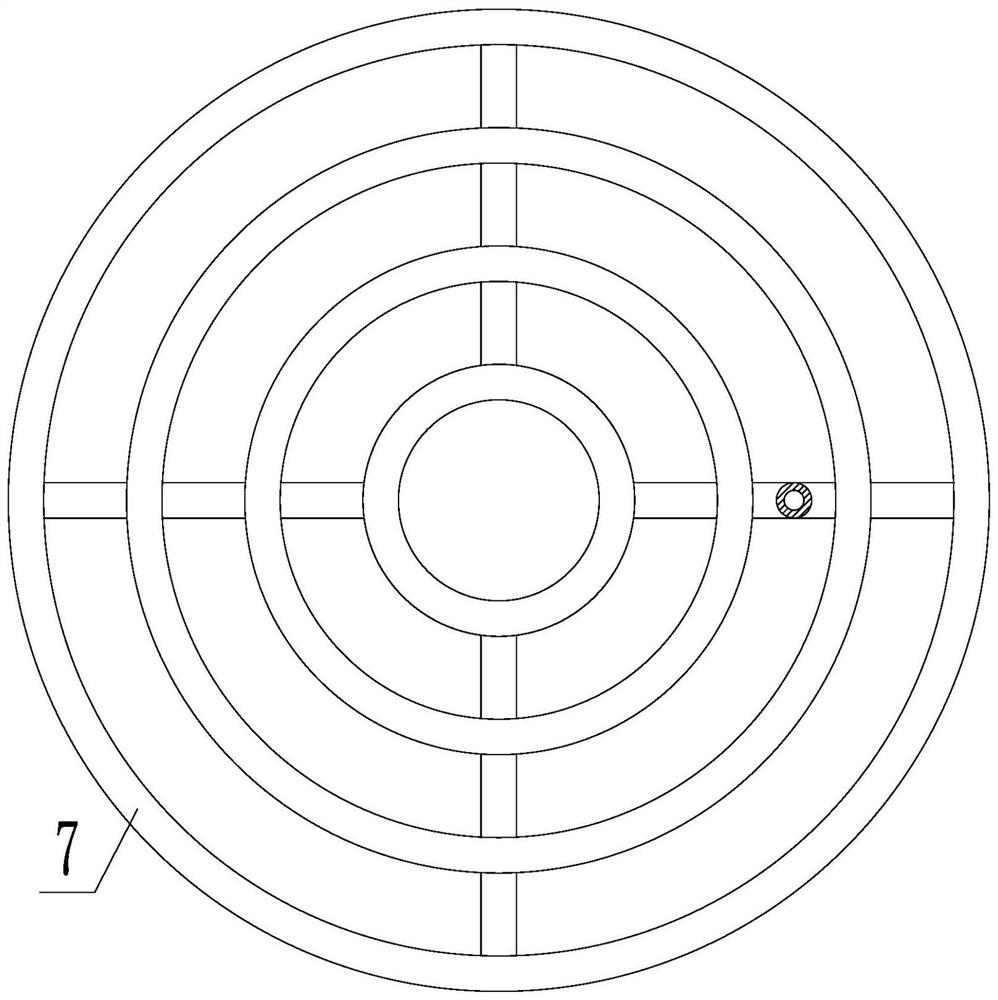

Method used

Image

Examples

Embodiment 1

[0052] A fiber-softening betel nut manufacturing method with extended shelf life, comprising the following steps:

[0053] S1. Raw material selection and cleaning: Select the betel nut dried fruits with good appearance and full particles from the betel nut dried fruits that have passed the purchase and acceptance inspection. Clean the dried betel nut fruit (a lot of dust, smoke, etc. adhering to the surface) and set aside;

[0054] S2, soaking treatment: put the dried betel nut fruit processed by S1 into the soaking seed tank, add water that is twice the weight of the dried betel nut fruit in the soaking seed tank, stir evenly, soak for 2h, and make the betel nut absorbed until the moisture content reaches 30 %;

[0055] S3. Corrosion and steam explosion treatment: The betel nut processed by S2 is taken out and drained and put into a steam explosion tank, and oxygen is introduced into the steam explosion tank. Saturated steam is introduced into the blasting tank. The pressur...

Embodiment 2

[0066]A fiber-softening betel nut manufacturing method with extended shelf life, comprising the following steps:

[0067] S1. Raw material selection and cleaning: Select the betel nut dried fruits with good appearance and full particles from the betel nut dried fruits that have passed the purchase and acceptance inspection. Clean the dried betel nut fruit (a lot of dust, smoke, etc. adhering to the surface) and set aside;

[0068] S2, soaking treatment: put the dried betel nut fruit processed by S1 into the soaking seed tank, add water that is 4 times the weight of the dried betel nut fruit in the soaking seed tank, stir evenly, soak for 4h, and make the betel nut absorbed until the moisture content reaches 40 %;

[0069] S3. Corrosion and steam explosion treatment: The betel nut processed by S2 is taken out and drained and put into a steam explosion tank, and oxygen is introduced into the steam explosion tank. Saturated steam is introduced into the blasting tank. The pressu...

Embodiment 3

[0080] A fiber-softening betel nut manufacturing method with extended shelf life, comprising the following steps:

[0081] S1. Raw material selection and cleaning: Select the betel nut dried fruits with good appearance and full particles from the betel nut dried fruits that have passed the purchase and acceptance inspection. Clean the dried betel nut fruit and set aside;

[0082] S2, soaking treatment: put the dried betel nut fruit processed by S1 into the soaking seed tank, add water that is 3 times the weight of the dried betel nut fruit in the soaking seed tank, stir evenly, soak for 3h, and make the betel nut absorbed until the moisture content reaches 35 %;

[0083] S3. Corrosion and steam explosion treatment: The betel nut processed by S2 is taken out and drained and put into a steam explosion tank. Oxygen is introduced into the steam explosion tank. The oxygen pressure is 0.15MPa, and the corrosion treatment is carried out for 1.5h. Saturated steam is introduced into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com