High-performance powder forging alloy material and preparation method thereof

A technology of powder forging and alloy materials, which is applied in the field of alloy forging, can solve the problems of low mechanical properties and incompetence, and achieve the effect of satisfying mechanical properties and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

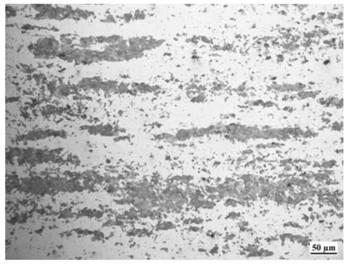

[0047] 1) Weigh 97.8% of elemental Fe, 1.6% of elemental Ni, and 0.6% of elemental Mo, melt and prepare Fe-Ni-Mo alloy, and then prepare Fe-Ni-Mo alloy by gas atomization or water atomization The obtained Fe-Ni-Mo alloy powder has a particle size of 25um-175um.

[0048] 2) Add 1% elemental Cu powder and 0.6% elemental C powder to the Fe-Ni-Mo alloy powder, and add 0.2% zinc stearate binder. Mix with a mixer at a speed of 60 revolutions per minute for 20 minutes to make the powder particles evenly distributed.

[0049] 3) Determine the size of the gear prepress according to the Deform finite element simulation software, design the cold press mold, and press the evenly distributed powder obtained in step 2) under 500MPa for 2 seconds for cold press forming to obtain the preset shape and Density of cold-pressed gear parts; among them, the factors affecting the size of the preform include changes in density during sintering, changes in density during partial forging, and changes ...

Embodiment 2

[0055] 1) Weigh 98.2% of elemental Fe, 1% of elemental Ni, and 0.8% of elemental Mo, melt and prepare Fe-Ni-Mo alloy, and then prepare Fe-Ni-Mo alloy by gas atomization or water atomization The obtained Fe-Ni-Mo alloy powder has a particle size of 25um-175um.

[0056] 2) Add 1.2% elemental Cu powder and 0.65% elemental C powder to Fe-Ni-Mo alloy powder, and add 0.3% zinc stearate binder. Mix with a mixer at a speed of 60 revolutions per minute for 20 minutes to make the powder particles evenly distributed.

[0057] 3) Determine the size of the gear prepress according to the Deform finite element simulation software, design the cold press mold, and press the evenly distributed powder obtained in step 2) under 500MPa for 2 seconds for cold press forming to obtain the preset shape and Density of cold-pressed gear parts; among them, the factors affecting the size of the preform include changes in density during sintering, changes in density during partial forging, and changes in ...

Embodiment 3

[0063] 1) Weigh 97.2% of elemental Fe, 2% of elemental Ni, and 0.8% of elemental Mo, melt and prepare Fe-Ni-Mo alloy, and then prepare Fe-Ni-Mo alloy by gas atomization or water atomization The obtained Fe-Ni-Mo alloy powder has a particle size of 25um-175um.

[0064] 2) Adding 1.5% elemental Cu powder and 0.8% elemental C powder to Fe-Ni-Mo alloy powder, and adding 0.5% zinc stearate binder. Use a mixer to mix the mixture for 25 minutes at a speed of 60 revolutions per minute to make the powder particles evenly distributed.

[0065] 3) Determine the size of the gear prepress according to the Deform finite element simulation software, design the cold press mold, and press the evenly distributed powder obtained in step 2) under 600MPa for 2 seconds for cold press forming to obtain the preset shape and Density of cold-pressed gear parts; among them, the factors affecting the size of the preform include changes in density during sintering, changes in density during partial forgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com