System with integration of evaporation, crystallization and separation

An evaporation crystallization and evaporation system technology, applied in the direction of solution crystallization, heat exchange cooling crystallization, chemical instruments and methods, etc., can solve the problems that the concentrated solution cannot be directly reused or crystallized, so as to reduce energy consumption, prevent scaling, and improve The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

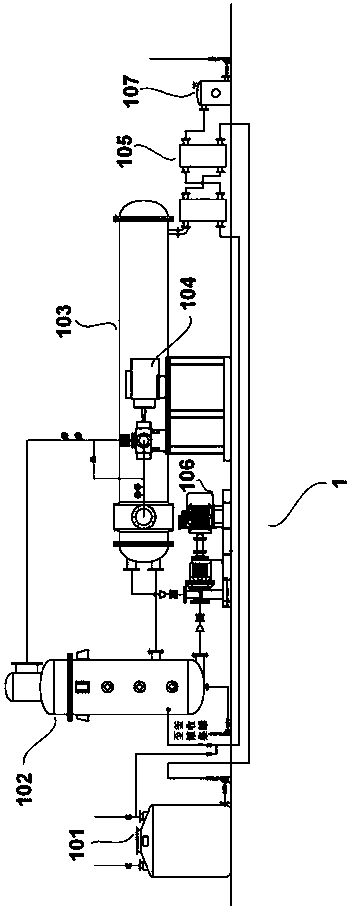

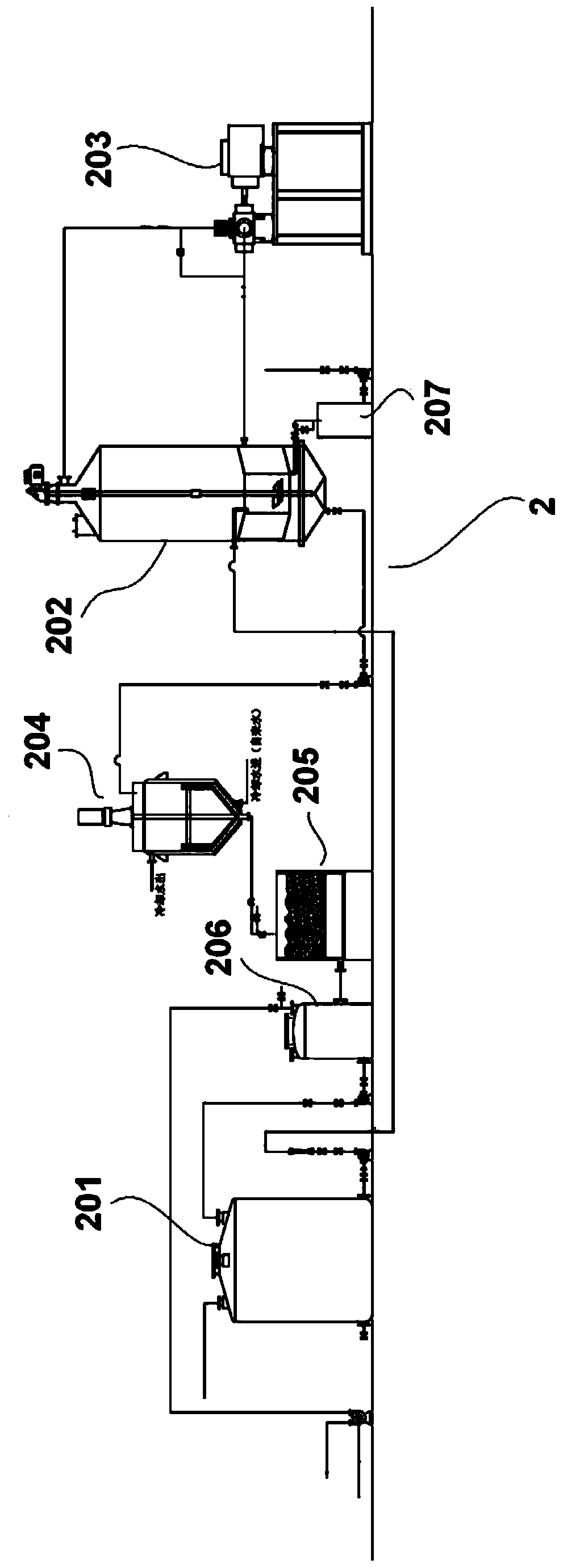

[0036] An embodiment of the integrated system of evaporation, crystallization and separation of the present invention, the schematic structure of this embodiment is as Figure 1~2 As shown, the evaporation and crystallization separation integrated system includes an evaporation system 1, a crystallization system 2 and a box (not shown in the figure). The evaporation system 1 and the crystallization system 2 are both arranged inside the box 3, and the box 3 It is a 3.0×3.3×12.0m carriage with an open top.

[0037] The evaporation system 1 includes a waste liquid storage tank 101, a gas-liquid separator 102 (φ1000mm×3700mm), an evaporation heater 103 (shell-and-tube heat exchanger, φ900×6000mm, double tube pass), and the first Roots vapor compression The machine 104 (2000kg / h, 132kW) and the plate heat exchanger 105, the volume of the waste liquid storage tank 101 is V=2000L, the liquid outlet of the waste liquid storage tank 101 is connected to two plate heat exchangers 105 in ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com