A method for co-processing red mud and iron-containing waste acid to produce titanium-rich slag and water purifier

A technology of water purifying agent and red mud, applied in the field of resources and environment, can solve the problems of high cost of concentrated waste acid, high cost of neutralization, solid waste of calcium sulfate, etc., achieve significant economic and environmental benefits, easy operation, and comprehensive cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

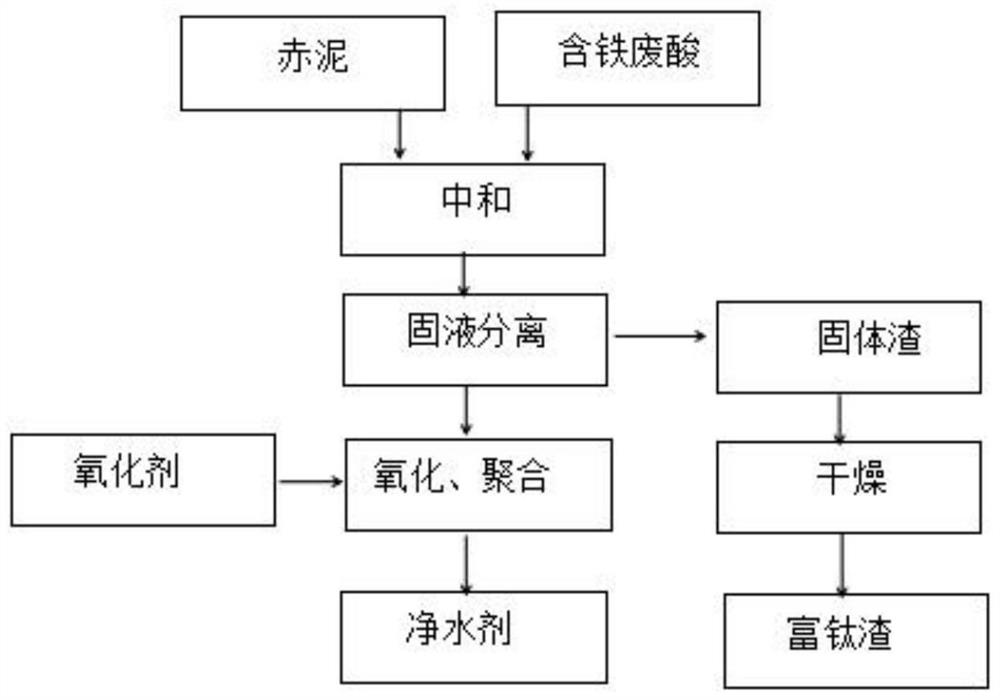

[0036] A method for co-processing red mud and iron-containing waste acid to produce titanium-rich slag and water purifier, the process is as follows figure 1 As shown, the steps are as follows:

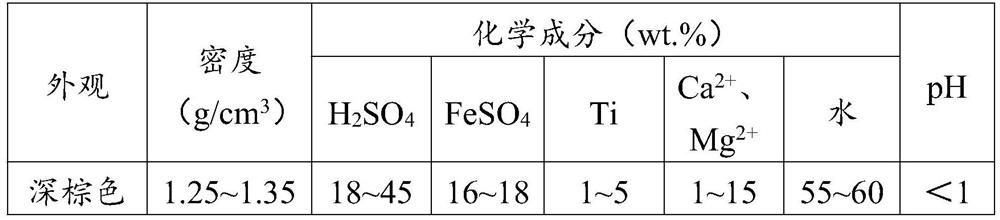

[0037] (1) Weighing 2000kg of Bayer red mud (1000kg dry, containing iron oxide 30wt%, titanium dioxide 6wt%, moisture 50wt%, sodium hydroxide, silicon, calcium and other components 14wt%) and 700kg titanium white waste sulfuric acid ( Containing sulfuric acid 40wt%, titanium dioxide 3wt%) into the reaction equipment, start stirring, heating and maintaining the reaction temperature of 65 ° C for neutralization reaction, until the pH is 3.5 to stop the reaction;

[0038] (2) The material after the reaction enters the filter press and carries out solid-liquid separation, and the main component of liquid is ferric sulfate, ferrous sulfate, sodium sulfate etc.; The main component of solid is silicon dioxide, titanium dioxide, calcium sulfate;

Embodiment 2

[0041] A method for co-processing red mud and iron-containing waste acid to produce titanium-rich slag and water purifier, the process is as follows figure 1 As shown, the steps are as follows:

[0042] (1) Weigh 2000kg of Bayer red mud (1000kg dry, containing 30wt% iron oxide, 6wt% titanium dioxide, 50wt% moisture, 14wt% other components such as sodium hydroxide, silicon, calcium) and 3500kg carbon steel pickling waste Sulfuric acid (containing sulfuric acid 10wt%, iron-containing 9.2wt%) was added to the reaction equipment, started stirring, heated and kept the reaction temperature at 75°C for neutralization reaction until the pH was 2.5 to stop the reaction;

[0043] (2) material after reaction enters filter press and carries out solid-liquid separation, and the main component of liquid is ferric sulfate, ferrous sulfate, sodium sulfate; The main component of solid is silicon dioxide, titanium dioxide, calcium sulfate;

Embodiment 3

[0046] A method for co-processing red mud and iron-containing waste acid to produce titanium-rich slag and water purifier, the process is as follows figure 1 As shown, the steps are as follows:

[0047] (1) Weigh 2000kg of combined red mud (1400kg dry, containing 5wt% iron oxide, 7wt% titanium dioxide, 30wt% moisture, 13wt% silicon dioxide, 35wt% calcium oxide, 10wt% other components) and 5000kg carbon steel Pickling waste hydrochloric acid (containing 10wt% hydrochloric acid and 10wt% iron) was added to the reaction equipment, started stirring, heating and maintaining the reaction temperature of 80°C for neutralization reaction until the pH was 5 to stop the reaction;

[0048] (2) The material after the reaction enters the filter press and carries out solid-liquid separation, and the main component of liquid is ferric chloride, ferrous chloride, calcium chloride, sodium chloride; The main component of solid is silicon dioxide, titanium dioxide;

[0049] (3) 170kg of 30% hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com