W-W2N strengthening and toughening nanometer multi-layer coating and preparation method thereof

A nano-multilayer and coating technology, applied in the coating, metal material coating process, ion implantation plating and other directions, can solve the problem of limited effect of strengthening and toughening, reduce residual stress, improve strength and toughness, The effect of a low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

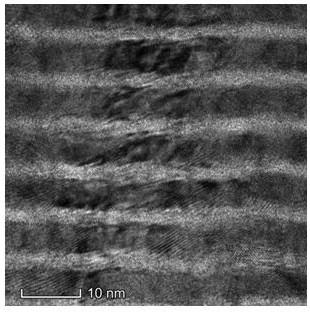

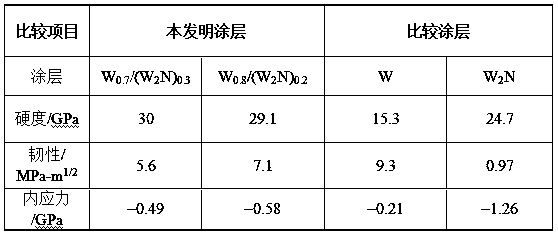

[0025] see figure 1 , W-W in Example 1 2 N nanometer multilayer coating includes a soft layer W layer with dark stripes, and a hard layer W layer with light stripes 2 N layer, soft layer W layer and hard layer W 2 N layers are alternately formed on the surface of the base material. This kind of W-W with modulation period composed of soft layer and hard layer 2 N nanometer multilayer coating has a thickness of 1 μm, a hardness of 30 GPa, and a toughness of 5.6 MPa-m 1 / 2 , the internal stress can be controlled to -0.49GPa, the modulation period is 10nm, the W single layer in this modulation structure is 7nm, W 2 The N monolayer is 3nm, and a relatively obvious columnar crystal morphology can be seen, and the coating exhibits a good multilayer structure. And it can be observed that the W layer and the W 2 A sharp interface is formed between the N layer, the W layer and the W 2 A semi-coherent interface is formed between the N layers. This is due to the fact that the semi...

Embodiment 2

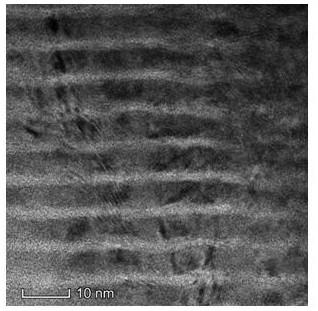

[0034] see figure 2 , W-W in Example 2 2 N nanometer multilayer coating includes a soft layer W layer with dark stripes, and a hard layer W layer with light stripes 2 N layer, soft layer W layer and hard layer W 2 N layers are alternately formed on the surface of the base material. This kind of W-W with modulation period composed of soft layer and hard layer 2 N nanometer multilayer coating has a thickness of 1μm, a hardness of 29.1GPa, and a toughness of 7.1MPa-m 1 / 2 , the internal stress can be controlled to -0.58GPa, the modulation period is 10nm, the W monolayer in this modulation structure is 8nm, and the W 2 The N monolayer is 2nm, and a relatively obvious columnar crystal morphology can be seen, and the coating exhibits a good multilayer structure. At the same time, it can be observed that the W layer and the W 2 A sharp interface is formed between the N layer, the W layer and the W 2 A semi-coherent interface is formed between the N layers. This is due to the ...

Embodiment 3

[0047] W-W 2 The N metal-ceramic nano multilayer coating includes a modulated structure periodically arranged on the surface of the base material, and the modulated structure is that soft phases and hard phases are periodically arranged alternately on the surface of the base material.

[0048] W-W 2 The thickness of the N nanometer multilayer coating is 1 μm.

[0049] The modulation period of the modulation structure is a fixed value of 10 nm.

[0050] The soft phase is a metal phase, and the thickness of a single layer of the metal phase is 6nm.

[0051] The hard phase is a ceramic phase, and the single layer thickness of the ceramic phase is 4nm.

[0052] W is used as the soft phase of the metal-ceramic nano multilayer coating, and the thickness of the single layer is 6nm.

[0053] W 2 N is used as the hard phase of the metal-ceramic nano multilayer coating, and the thickness of the single layer is 4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com