Analysis method for contact stress distribution of gradient elastic grinding and polishing disc

A contact stress, analytical method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of poor processing efficiency and quality controllability, uneven material removal, high cost, and improve processing. Efficiency and process quality, increased design accuracy, simplified problem solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

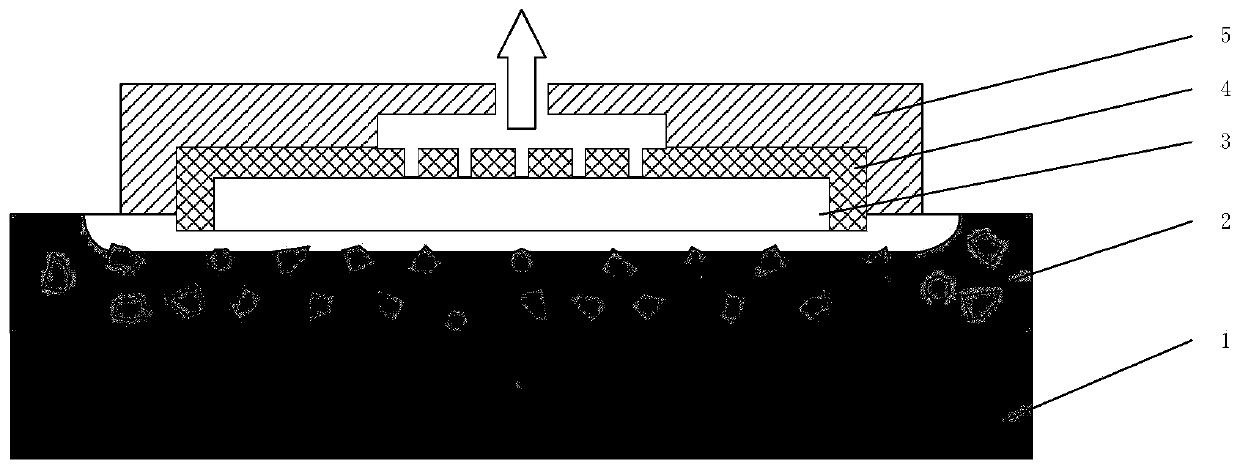

[0052] The present invention will be further explained below in conjunction with the drawings:

[0053] Such as Figure 1~7 As shown, the invention relates to a gradient-based elastic polishing plate including a rigid layer of the polishing plate 1, an elastic gradient layer of the polishing plate 2, a workpiece 3, a mold 4 and a workpiece fixing plate 5. The elastic gradient layer 2 of the polishing plate is fixed on the polishing plate Above the rigid layer 1, the workpiece 3 is mounted on the workpiece mounting plate 5 through the matching mold 4, and the workpiece 3 is set directly above the elastic gradient layer 2 of the polishing plate.

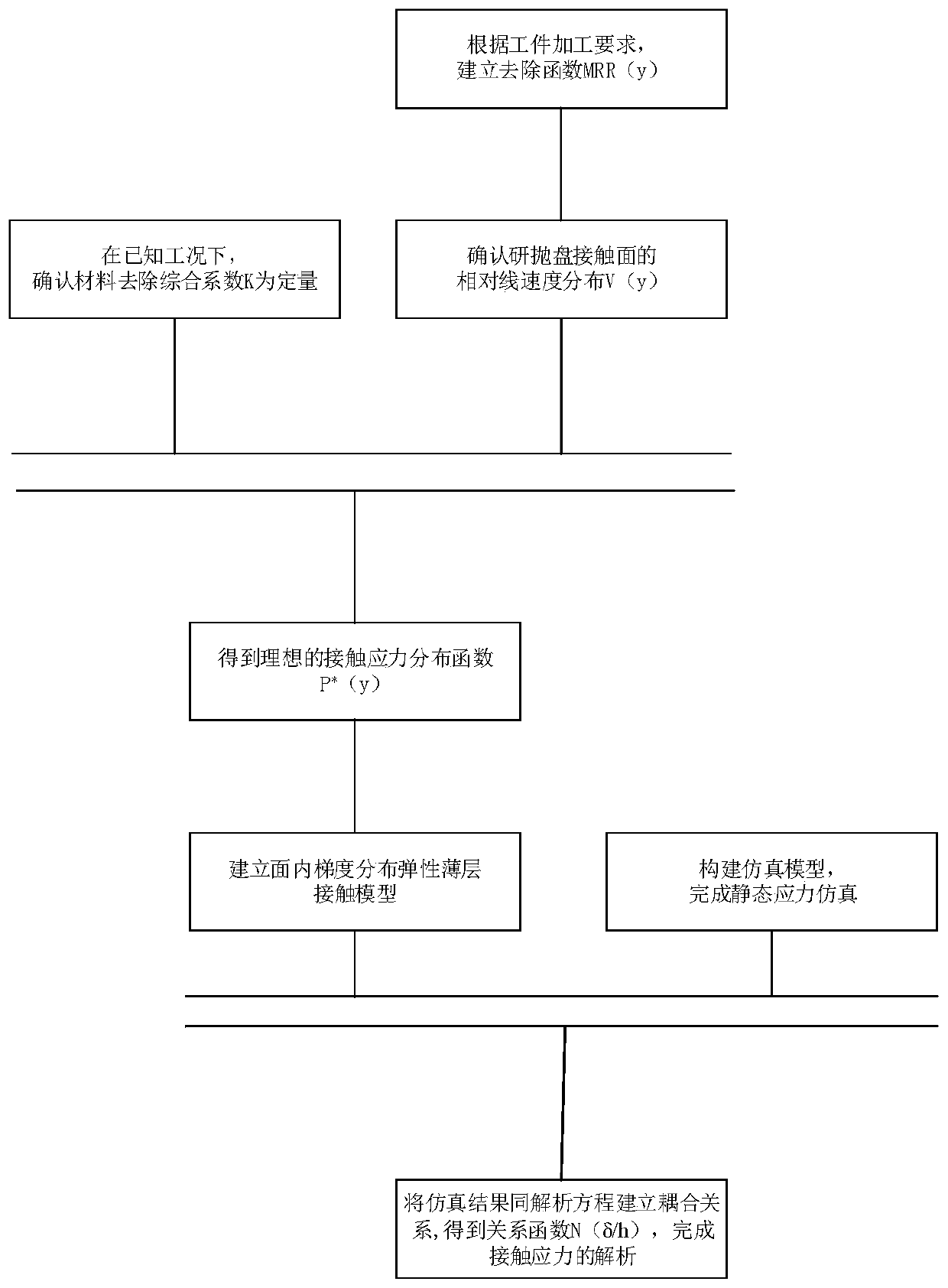

[0054] An analytical method for the contact stress distribution of a gradient elastic polishing disc, including the following steps:

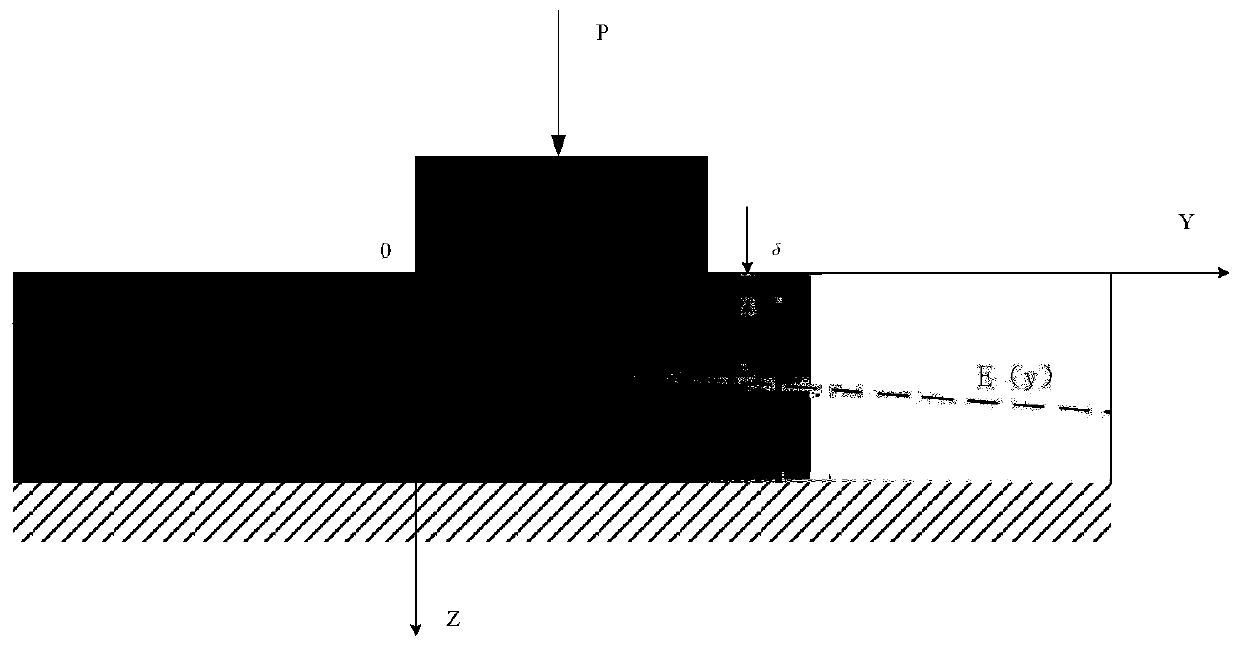

[0055] Step 1: First, establish the removal function MRR(y) according to the processing requirements of the workpiece, select the appropriate angular velocity ω, then the relative linear velocity distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com