a fef 3 Composite cathode material and preparation method thereof

A composite positive electrode material and powder technology, which is applied in the field of FeF3 composite positive electrode material and its preparation, can solve the problems such as poor conductivity of materials, poor conductivity between material particles, and influence on the safety performance of thermal batteries. Swelling problem, large usable specific capacity, effect of high operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

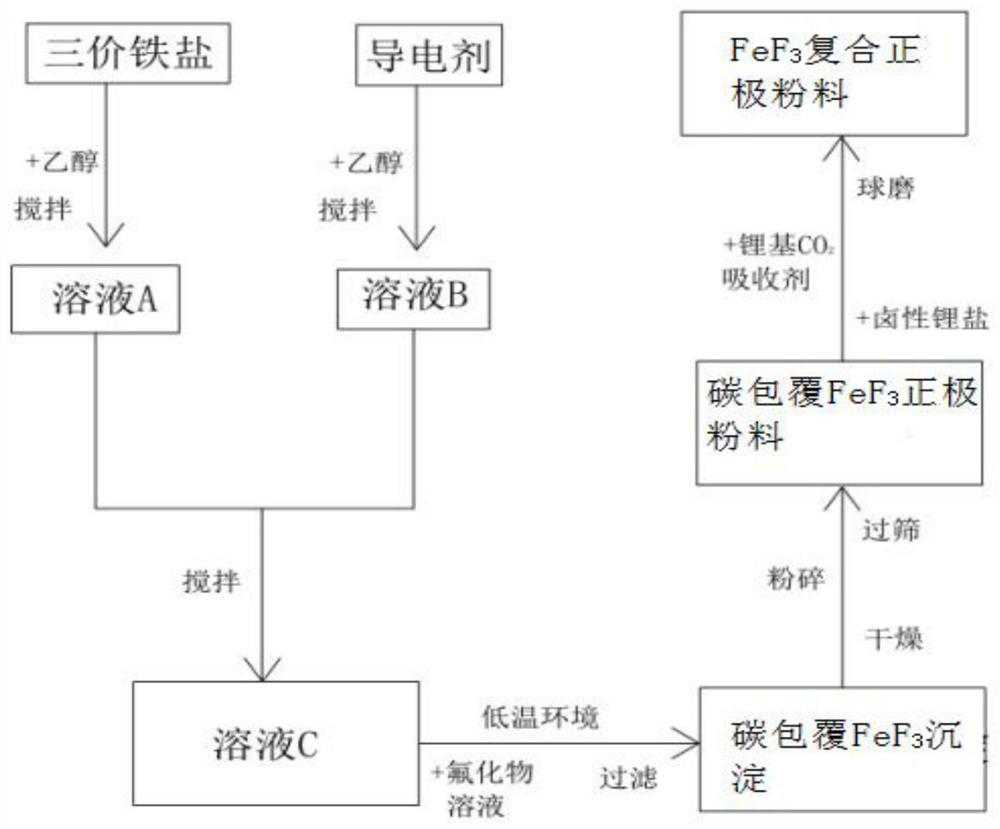

[0027] a FeF 3 The preparation method of composite cathode material comprises the following steps:

[0028] (1) Take Fe(NO) 3 Dissolved in ethanol, stirred evenly, prepared solution A; took carbon nanotubes dissolved in ethanol, stirred evenly, prepared solution B;

[0029] (2) Mix solution A and solution B in proportion to form solution C, mix the fluoride solution and solution C at -5°C to 8°C, stir and react for 10 hours, and filter to obtain carbon-coated FeF 3 Precipitation; Among them, Fe(NO) in solution C 3 The mass ratio to carbon nanotubes is 100:1;

[0030] (3) Carbon coated FeF 3 The precipitate was placed in a vacuum drying oven, dried at 60°C for 8 hours, crushed, and passed through a 300-mesh sieve to obtain carbon-coated FeF 3 Positive electrode powder;

[0031] (4) Carbon-coated FeF 3 The positive electrode powder is mixed with 30% of its mass LiF and 2% to its mass of Li 2 ZrO 3 , ball milled at a rate of 100r / min for 4h to obtain FeF 3 Composite cat...

Embodiment 2

[0033] a FeF 3 The preparation method of composite cathode material comprises the following steps:

[0034] (1) Take FeCl 3 Dissolved in ethanol, stirred evenly, prepared solution A; dissolved graphene in ethanol, stirred evenly, prepared solution B;

[0035] (2) Mix solution A and solution B in proportion to form solution C, mix the fluoride solution and solution C at -5°C to 8°C, stir and react for 12 hours, and filter to obtain carbon-coated FeF 3 Precipitation; Among them, FeCl in solution C 3 The mass ratio to graphene is 100:6;

[0036] (3) Carbon coated FeF 3The precipitate was placed in a vacuum drying oven, dried at 100°C for 6 hours, crushed, and passed through a 200-mesh sieve to obtain carbon-coated FeF 3 Positive electrode powder;

[0037] (4) Carbon-coated FeF 3 The positive electrode powder is mixed with 5% of its mass LiCl and its mass of 10% Li 4 SiO 4 , ball milled at a rate of 100-1000r / min for 1-4h to obtain FeF 3 Composite cathode powder.

Embodiment 3

[0039] a FeF 3 The preparation method of composite cathode material comprises the following steps:

[0040] (1) Dissolve the ferric salt in ethanol and stir evenly to prepare solution A; dissolve the conductive agent in ethanol and stir uniformly to obtain solution B; wherein the ferric salt is Fe(NO) 3 , FeCl 3 The mixture, conductive agent is the mixture of graphene, KS-6 graphite;

[0041] (2) Mix solution A and solution B in proportion to form solution C, mix the fluoride solution and solution C at -5°C to 8°C, stir and react for 24 hours, and filter to obtain carbon-coated FeF 3 Precipitation; wherein, the mass ratio of the ferric salt to the conductive agent in solution C is 100:10;

[0042] (3) Carbon coated FeF 3 The precipitate was placed in a vacuum drying oven, dried at 150°C for 2 hours, crushed, and passed through a 100-mesh sieve to obtain carbon-coated FeF 3 Positive electrode powder;

[0043] (4) Carbon-coated FeF 3 The positive electrode powder is mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com