A Baked Oil Essence

An essence and oil-baked technology, applied in hair care, devices for washing hair or scalp, and cosmetic preparations, etc., can solve problems such as easy to cause adverse effects, low product source safety, long oil-baking time, etc., to achieve soft and shiny hair. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

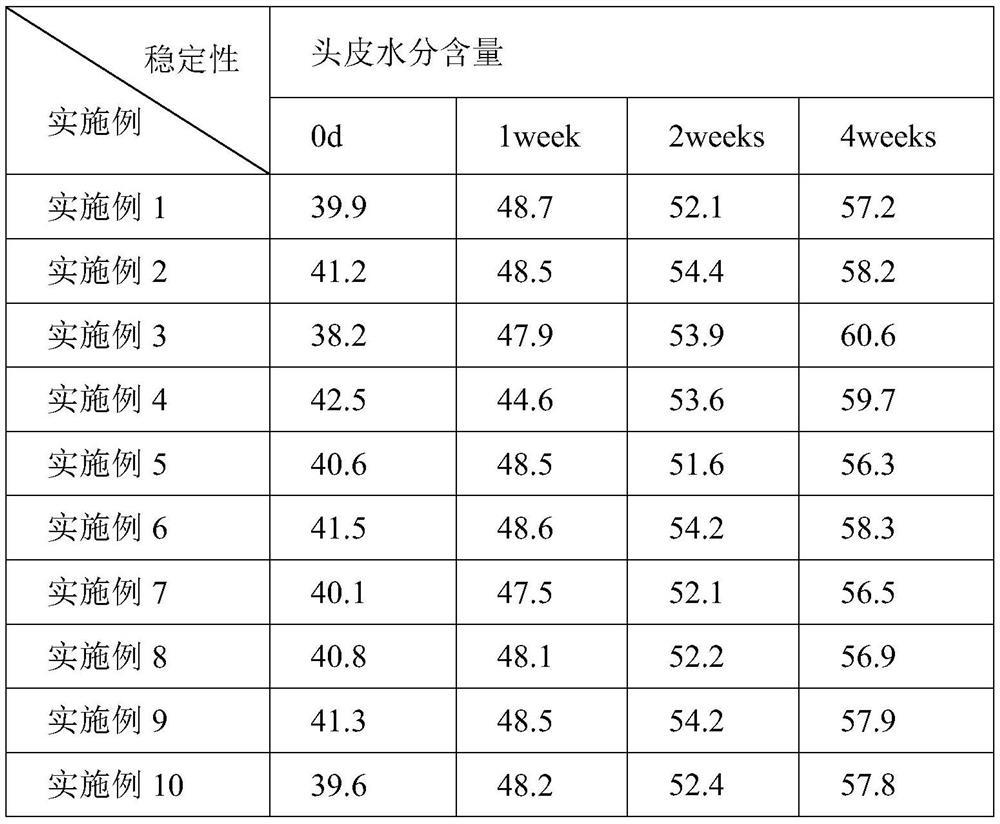

Examples

preparation example Construction

[0076] A second aspect of the present invention provides a method for preparing a baked oil essence, the steps comprising:

[0077] (1) Add 1 / 3 deionized water and thickener to the stirring pot, stir for 3-10min, then put in pre-dissolved sodium hydroxide, and stir for 8-15min;

[0078] (2) After the thickener is completely dissolved, add the cationic conditioner, stir for 8-15min, turn on the heating, and put in the emulsifier, to be heated to 75-85°C;

[0079] (3) After the emulsifier is basically dissolved, add humectant, pH adjuster and chelating agent, continue stirring for 5-10min, keep the temperature at 75-85°C, after the material is completely dissolved, vacuum and homogenize for 8-15min, continue to keep warm Stir for 20-40min;

[0080] (4) Turn on cooling water and slowly cool down to 50-55°C, put in the remaining deionized water, apply silicone oil conditioner, vacuumize, continue stirring to cool down to 40-45°C, put in plant extracts and preservatives, stir Aft...

Embodiment 1

[0093] Embodiment 1 provides a kind of baked oil essence, which includes the following components by weight: 3 parts of silicone oil conditioner for hair, 0.7 part of cationic conditioner, 0.5 part of protein amino acid conditioner, 0.6 part of emulsifier, moisturizing agent 1 part, 0.3 part of preservative, 0.01 part of chelating agent, 0.001 part of pH adjuster, 0.5 part of thickener, 0.5 part of plant extract, 50 parts of deionized water.

[0094] The silicone oil conditioner is a mixture obtained by compounding amino-terminated polydimethylsiloxane, cyclopentasiloxane and polydimethylsiloxane in a weight ratio of 2:2:5;

[0095] Described cationic conditioning agent is the mixture that polyquaternium-37 and behenyltrimethylammonium chloride are compounded according to weight ratio of 4:3;

[0096] The protein amino acid conditioner is corn gluten amino acid;

[0097] Described emulsifier is the mixture that cetearyl alcohol and sodium isostearoyl lactylate are compounded ...

Embodiment 2

[0105] Embodiment 2 provides a kind of baked oil essence, which comprises the following components in parts by weight: 13.5 parts of silicone oil conditioner for hair, 3.9 parts of cationic conditioner, 3 parts of protein amino acid conditioner, 3.4 parts of emulsifier, moisturizing agent 5 parts, 1.4 parts of preservative, 0.06 part of chelating agent, 0.004 part of pH adjuster, 2 parts of thickener, 3 parts of plant extract, 100 parts of deionized water.

[0106] The silicone oil conditioner is a mixture obtained by compounding amino-terminated polydimethylsiloxane, cyclopentasiloxane and polydimethylsiloxane in a weight ratio of 2:2:5;

[0107] The cationic conditioning agent is a mixture obtained by compounding polyquaternium-37, behenyltrimethylammonium chloride, and guar hydroxypropyltrimethylammonium chloride in a weight ratio of 5:5:3;

[0108] The protein amino acid conditioner is corn gluten amino acid;

[0109] Described emulsifier is the mixture that cetearyl alco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com