Finger sleeve cleaning process and equipment used by process

A finger sleeve and process technology, which is applied to the finger sleeve cleaning process and the equipment used in the process, can solve the problems of general cleaning effect, high manufacturing cost, and low cleaning efficiency, so as to reduce the work intensity of workers, facilitate use and operation, Easy clean up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

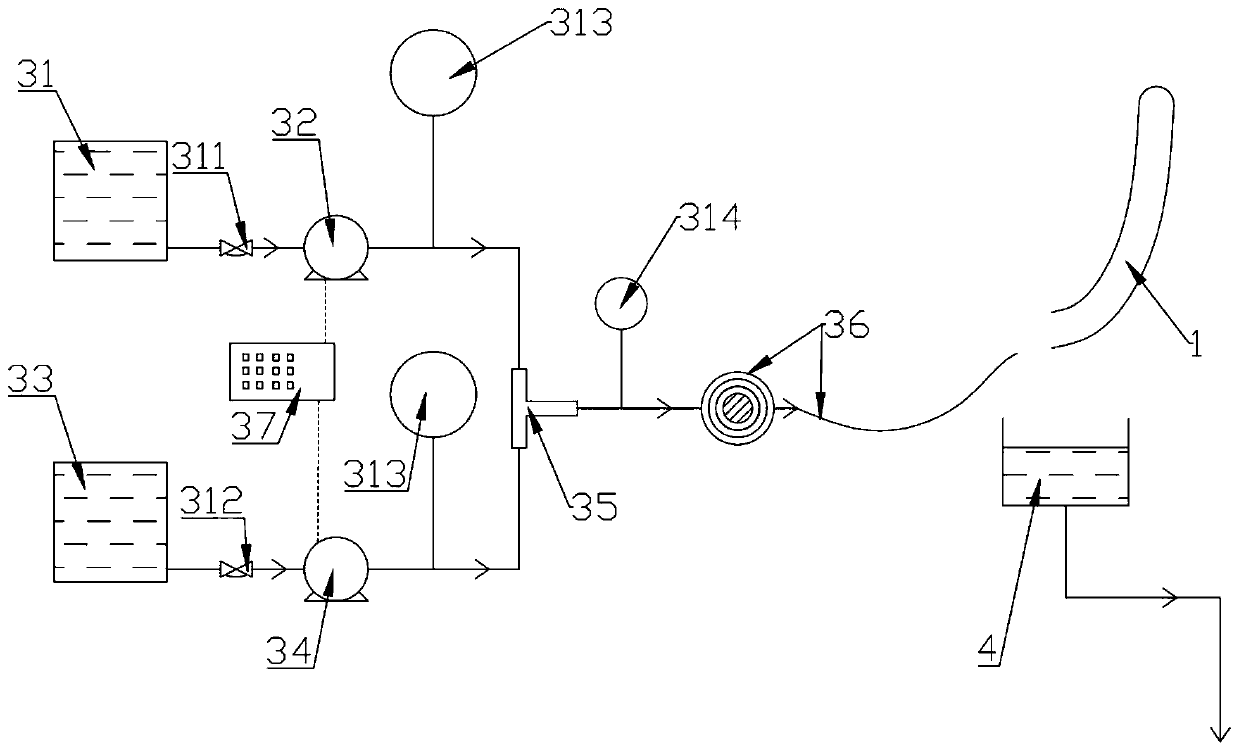

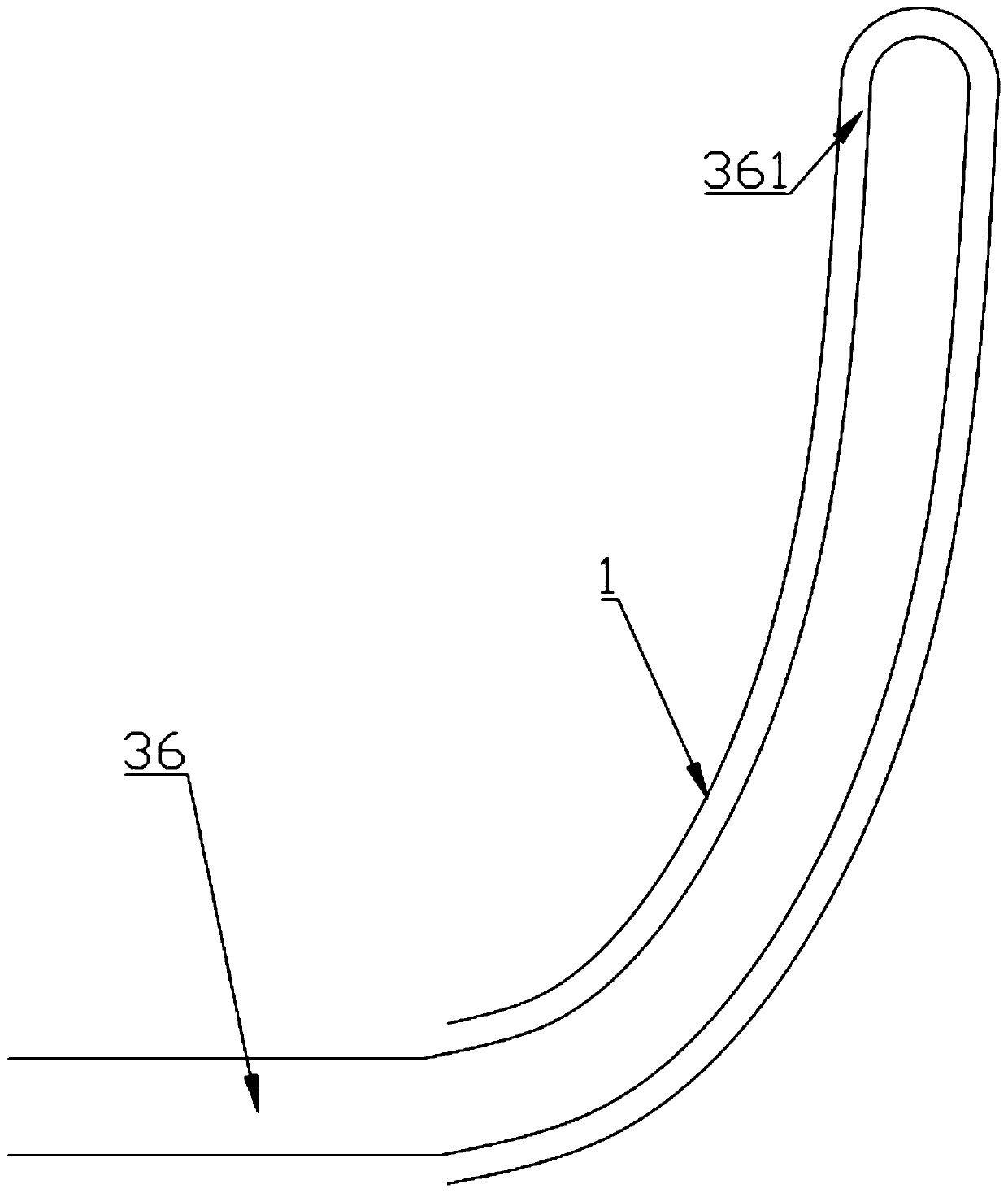

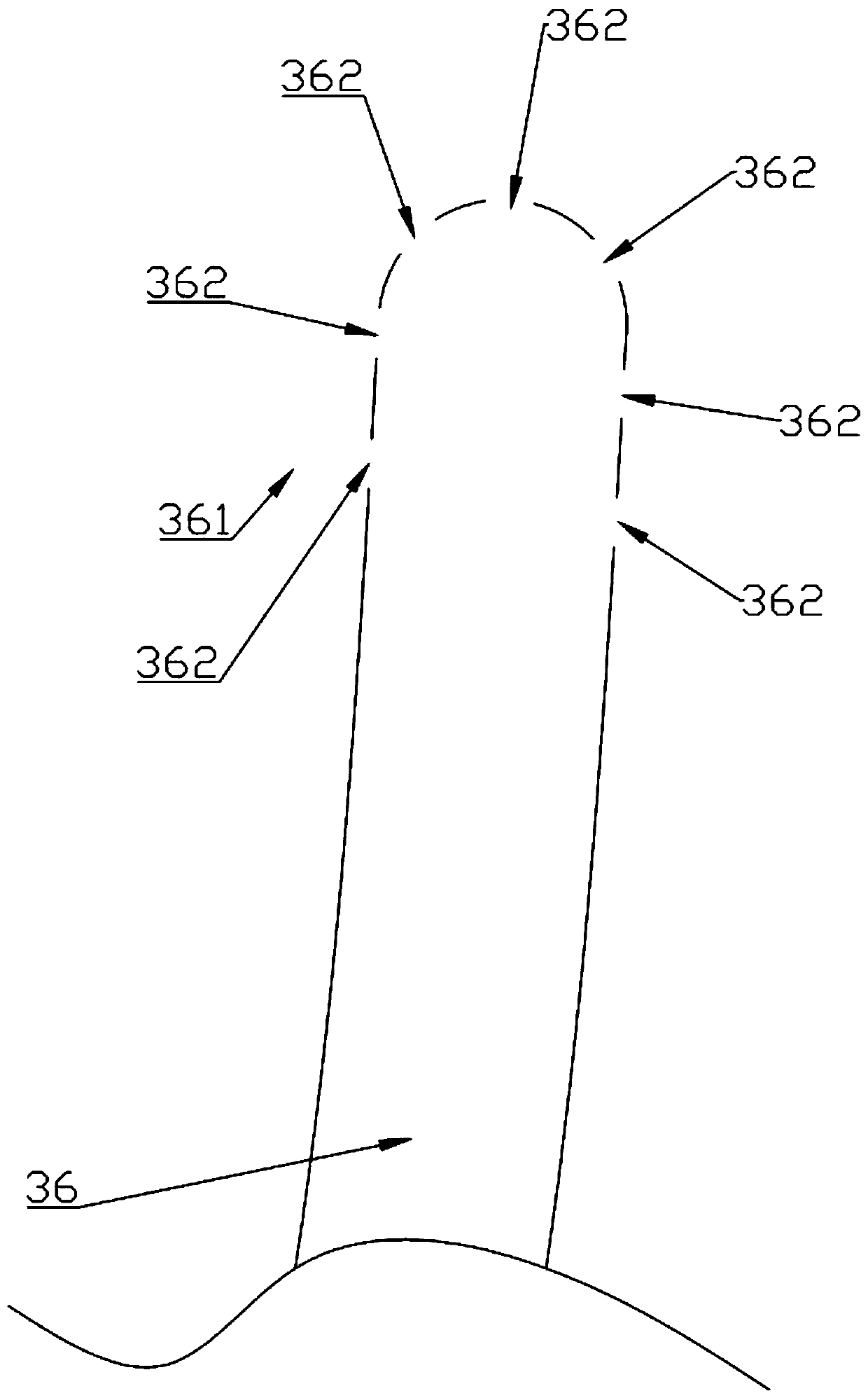

Method used

Image

Examples

Embodiment 1

[0062] A kind of finger sleeve cleaning process, comprises the following steps:

[0063] S1. Put the nylon hose deep into the inside of the finger sleeve, and block the liquid outlet of the finger sleeve, inject the cleaning solution into the inside of the finger sleeve through the nylon hose, and make the cleaning solution chemically soak the inside of the finger sleeve. The soaking time is 10-15 minutes;

[0064] S2. After soaking, open the liquid outlet of the finger cannula to empty the cleaning solution; introduce compressed air into the finger cannula, and use the compressed air to quickly discharge the cleaning solution in the finger cannula; the duration of this process is 3~ 5 minutes, the compressed air pressure range is 0.65~0.8MPa;

[0065] S3. Inject water into the finger sleeve through a nylon hose, and rinse continuously to clean the dirt in the tube; the washing time is 10 to 15 minutes, and the water pressure is not lower than 0.7MPa during washing;

[0066]...

Embodiment 2

[0070] A kind of finger sleeve cleaning process, comprises the following steps:

[0071] S1. Put the nylon hose deep into the inside of the finger sleeve, and block the liquid outlet of the finger sleeve, inject the cleaning solution into the inside of the finger sleeve through the nylon hose, and make the cleaning solution chemically soak the inside of the finger sleeve. The soaking time is 10-15 minutes;

[0072] Dissolve and peel off foreign matter such as crystals, impurities, lubricants, etc. on the inner wall of the finger cannula, so that the inner wall of the finger cannula can be cleaned through subsequent processes to reduce the radioactive level.

[0073] S2. After soaking, open the liquid outlet of the finger cannula to empty the cleaning solution; introduce compressed air into the finger cannula, and use the compressed air to quickly discharge the cleaning solution in the finger cannula; the duration of this process is 3~ 5 minutes, the compressed air pressure ra...

Embodiment 3

[0081] A kind of finger sleeve cleaning process, comprises the following steps:

[0082] S1. Put the nylon hose deep into the inside of the finger sleeve, and block the liquid outlet of the finger sleeve, inject the cleaning solution into the inside of the finger sleeve through the nylon hose, and make the cleaning solution chemically soak the inside of the finger sleeve. The soaking time is 10-15 minutes;

[0083] Dissolve and peel off foreign matter such as crystals, impurities, lubricants, etc. on the inner wall of the finger cannula, so that the inner wall of the finger cannula can be cleaned through subsequent processes to reduce the radioactive level.

[0084] S2. After soaking, open the liquid outlet of the finger cannula to empty the cleaning solution; introduce compressed air into the finger cannula, and use the compressed air to quickly discharge the cleaning solution in the finger cannula; the duration of this process is 3~ 5 minutes, the compressed air pressure ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com