Low-temperature-resistant low-air-permeability silicon resin coating composition and preparation method thereof

A technology of silicone resin and hydroxy silicone oil, which is applied in the direction of coating, etc., can solve the problems of circuit boards, photoelectric devices, vulcanization failure, inability to prevent sulfur vapor penetration, inspection of use requirements, etc., to solve the problem of device failure, improve toughness, and improve The effect of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

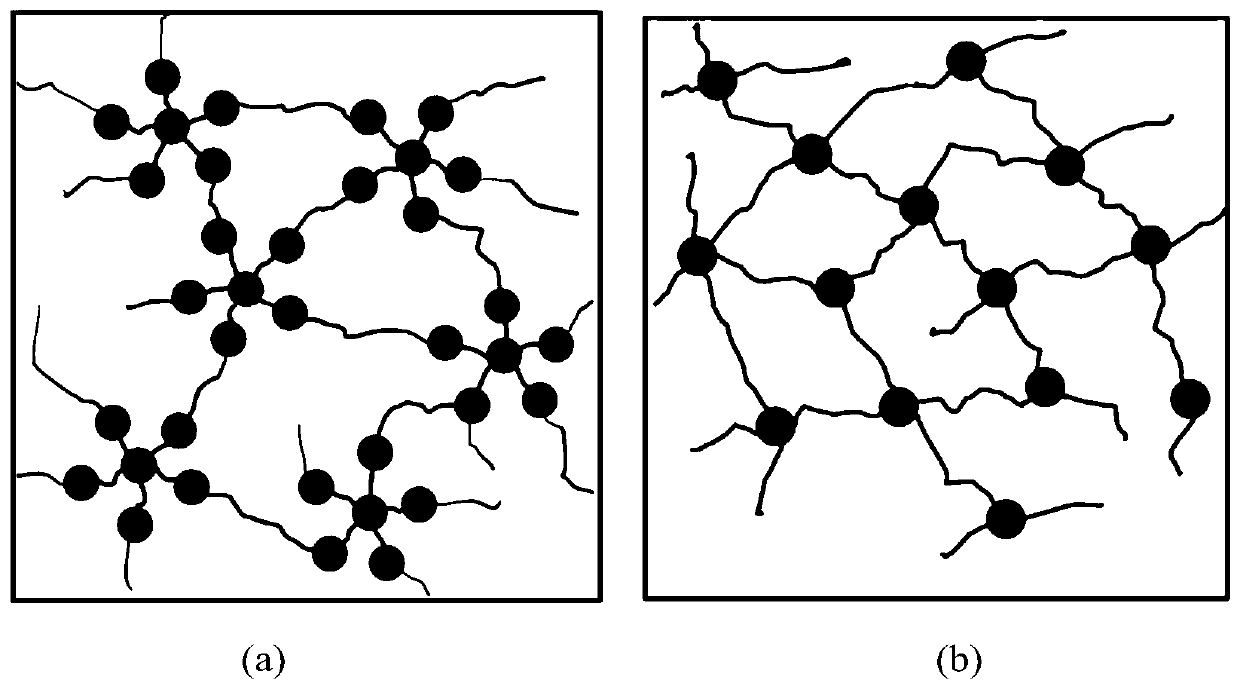

Problems solved by technology

Method used

Image

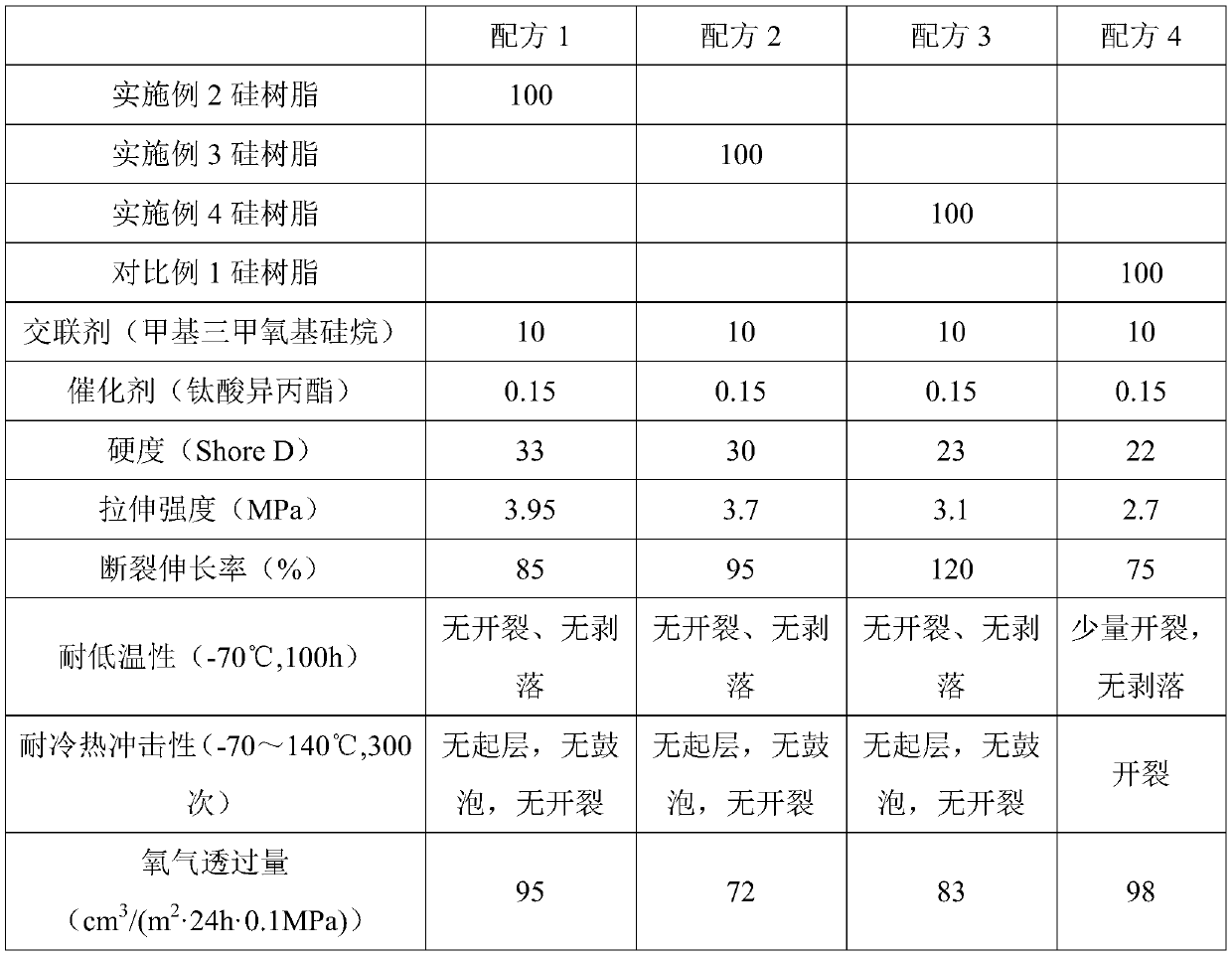

Examples

Embodiment 1

[0035] Add 118 g of deionized water, 500 g of toluene, and 6 g of hydrochloric acid (concentration: 37%) into the reaction flask, stir evenly, and add 500 g of phenyltrimethoxysilane dropwise. After the addition, the temperature was raised to reflux, reacted for 2h, and then cooled to room temperature. The reaction solution was washed with deionized water until neutral. The organic phase was collected and dried overnight with anhydrous calcium chloride. Calcium chloride was filtered, and the filtrate was concentrated to remove toluene to obtain 310 g of trifunctional silicone resin prepolymer.

Embodiment 2

[0037] Get the prepolymer 80g prepared in Example 1, dimethyl hydroxy silicone oil (100mPa s) 15.3g, trifluoropropyl methyl hydroxy silicone oil (100mPa s) 32.24g, dissolve with 800g toluene, add reaction bottle, Furthermore, 0.3 g of trifluoromethanesulfonic acid was added. Heat to reflux for 1h, remove the generated water with a water separator; then add 15.3g of dimethyl hydroxy silicone oil (100mPa s), 32.24g of trifluoropropyl methyl hydroxy silicone oil (100mPa s), and continue to reflux to remove water; 2h Then add 15.3g of dimethyl hydroxy silicone oil (100mPa·s) and 32.24g of trifluoropropyl methyl hydroxy silicone oil (100mPa·s), remove the generated water and continue reflux aging for 6h. Cool down after the reaction, add 1.5g of calcium carbonate to neutralize, and filter. Filtrate decompression distillation removes solvent, obtains average unit formula as (PhSiO 1.5 ) 0.32 (Me 2 SiO) 0.32 (CF 3 CH 2 CH 2 MeSiO) 0.32 (OH) 0.04 of solid silicone.

Embodiment 3

[0039] Get the prepolymer 80g prepared in Example 1, dimethyl hydroxy silicone oil (100mPa s) 7.6g, trifluoropropyl methyl hydroxy silicone oil (100mPa s) 48.3g, dissolve with 800g toluene, add reaction flask, Furthermore, 0.5 g of trifluoromethanesulfonic acid was added. Heat to reflux for 1h, remove the generated water with a water separator; then add 7.6g of dimethyl hydroxy silicone oil (100mPa s), 48.3g of trifluoropropyl methyl hydroxy silicone oil (100mPa s), and continue to reflux to remove water; 2h Then add 7.6g of dimethyl hydroxy silicone oil (100mPa·s) and 48.3g of trifluoropropyl methyl hydroxy silicone oil (100mPa·s), remove the generated water and continue to reflux for 6.5h of aging. Cool down after the reaction, add 2.5g of calcium carbonate for neutralization, and filter. Filtrate decompression distillation removes solvent, obtains average unit formula as (PhSiO 1.5 ) 0.32 (Me 2 SiO) 0.16 (CF 3 CH 2 CH 2 MeSiO) 0.49 (OH) 0.03 of solid silicone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com