A leak-stopping agent for foundation pit row pile enclosure wall and its application method

A leak-stopping agent and retaining wall technology, applied in chemical instruments and methods, infrastructure engineering, drilling compositions, etc., can solve the problems of low-strength leak-stopping agent, poor matching of base surface, high price, etc. Achieve low price, improve plugging effect, and improve impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] As a preferred embodiment of the present invention, this embodiment discloses:

[0041] A leak-stopping agent for foundation pit row pile enclosure walls, comprising the following raw materials by mass percentage: 50% of aluminate cement clinker, 6% of anhydrite, 16% of rice fiber, 16% of sodium bentonite, Walnut shell chips 12%.

[0042] After mixing the above four materials evenly, refer to the test of GB23440-2009 "Inorganic Waterproof Plugging Material" to obtain the performance index of the plugging agent of this embodiment: initial setting time 8min, final setting time 21min, 1h compressive strength 6MPa, 2h The compressive strength is 16.5MPa, and the 28d compressive strength is 48MPa.

[0043] In this example, the alkalinity coefficient of aluminate cement clinker is 0.9, the ratio coefficient of calcium aluminate is 3.0, the C2AS content is 7%, and the specific surface area of clinker grinding is 600m 2 / kg.

[0044] The specific surface area of anhydrit...

Embodiment 2

[0049] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

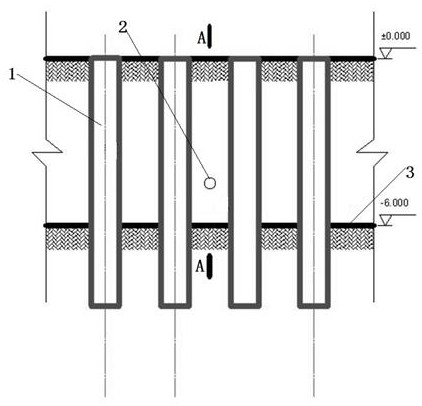

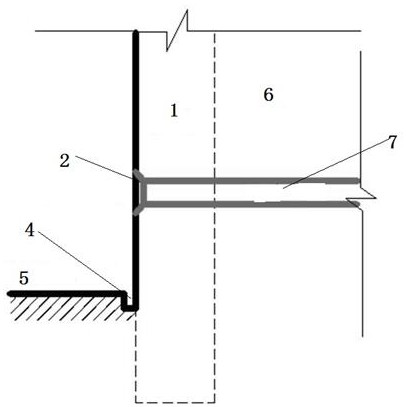

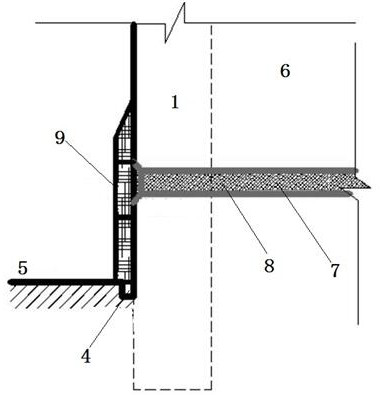

[0050] Utilize the leak-stopping agent in embodiment 1, block the water leakage 2 of 300mm on the retaining wall of row pile 1, as figure 1 As shown, in the foundation pit 5 of the foundation 3, a row of piles 1 and an enclosure wall are arranged, and a water leak 2 is arranged on the enclosure wall. The specific usage method is:

[0051] Step A, clean up the mud and stones on the surface of the leaking port 2, chisel the leaking port 2 into a funnel shape, and reduce the water pressure at the outlet of the leaking place; at the same time, put stones in the sack 9 for standby;

[0052] Step B. After fluffing the hemp rope fiber and cotton fiber, use pliers to stuff it into the water leak 2; the machine passes through the water leak 2 on the enclosure wall, and inserts the filling fiber 8 into the soil layer 6 behind the enclosure wall In the...

Embodiment 3

[0057] As another preferred embodiment of the present invention, this embodiment discloses:

[0058] A leak-stopping agent for pile-row retaining walls of foundation pits, comprising the following raw materials by mass percentage: 64% of aluminate cement clinker, 10% of anhydrite, 2% of straw fiber, 4% of sodium-based bentonite, Walnut shell chips 20%.

[0059] After mixing the above four materials evenly, refer to the test of GB23440-2009 "Inorganic Waterproof Plugging Material" to obtain the performance indicators of the plugging agent of this embodiment: initial setting time 7min, final setting time 18min, 1h compressive strength 7.3MPa, 2h compressive strength 17.6MPa, 28d compressive strength 54MPa.

[0060] In the present embodiment, the alkalinity coefficient of aluminate cement clinker is 0.85, the ratio coefficient of calcium aluminate is 2.5, and C 2 The content of AS is 15%, and the specific surface area of clinker grinding is 600m 2 / kg.

[0061] The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com