Sulfide solid electrolyte with core-shell structure, preparation method and solid battery

A technology of solid electrolyte and core-shell structure, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problem of the decline in the basic performance of sulfide solid electrolytes, such as conductivity, to slow down performance decay, improve stability, and improve weakening effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] The sulfide electrolyte Z was prepared as follows,

[0079] S1: Under the protection of argon atmosphere, weigh the lithium source, M source, Q source and X source according to the composition ratio of the general formula,

[0080] Lithium source: LiH, Li 2 S 2 , Li 2 S. Li 2 Se, Li 2 Se 2 One or more compositions in;

[0081] S source: S, H 2 S, P 2 S 5 ,P 4 S 9 ,P 4 S 3 , Se, P 2 Se 5 , Li 2 S 2 , Li 2 S. Li 2 Se, Li 2 Se 2 One or more compositions in;

[0082] P source: P, P 2 S 5 ,P 4 S 9 ,P 4 S 3 One or more compositions in;

[0083] X source is Li 2 X, X is one of Cl, Br, I, F;

[0084] Under the condition that the water content is less than 10ppm, the lithium source, the M source, the Q source and the X source are ground and mixed evenly to obtain a powder raw material;

[0085] S2: After grinding the powder primary material to a uniform particle size, pressure tableting to obtain a flake primary material;

[0086] S3: Put the flak...

Embodiment 1~6

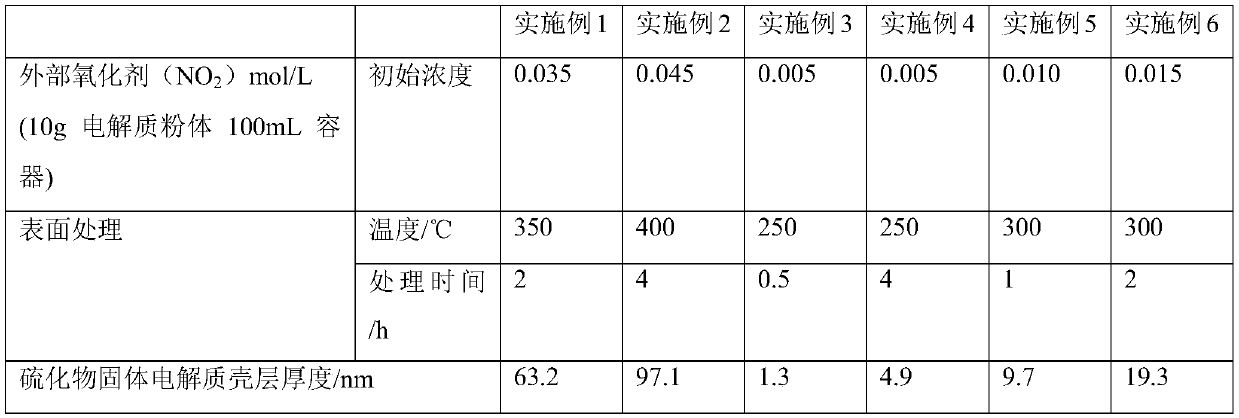

[0117] 10g Li prepared by Comparative Example 1 6 P.S. 5 Cl was placed in an ellipsoidal quartz bottle (100mL), and a filter cap was added to pump the negative pressure until the air pressure was 0.1 atm, and the NO was injected through a syringe. 2 , placed in a rotary electric furnace, heated and kept warm for surface treatment, and a sulfide solid electrolyte with a core-shell structure is obtained after cooling. The specific parameters of the preparation process are shown in Table 1. [Shell layer thickness test] was carried out on Examples 1-6 at the same time.

[0118] [Shell Thickness Test]

[0119] The sulfide solid electrolyte to be tested was subjected to a stripping-element determination test. The peel depth is referenced to Si. The concentration of O element was measured under different stripping depth conditions; the thickness of the shell was taken when the O element concentration was lower than the detection limit. The results are shown in Table 1.

[0120...

Embodiment 6~8

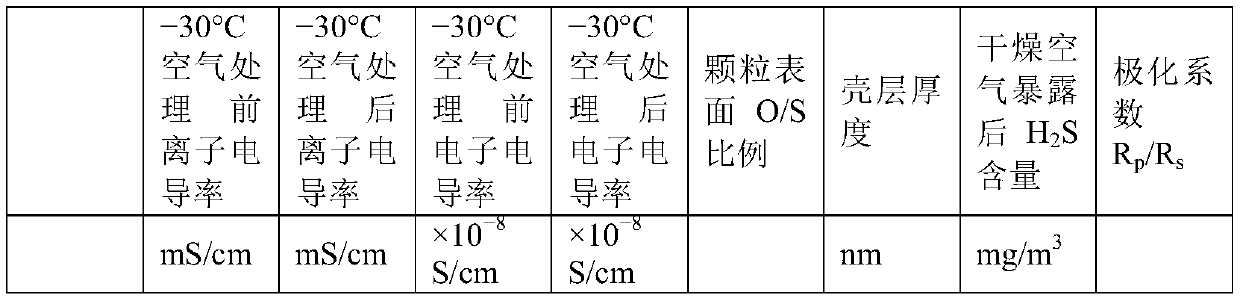

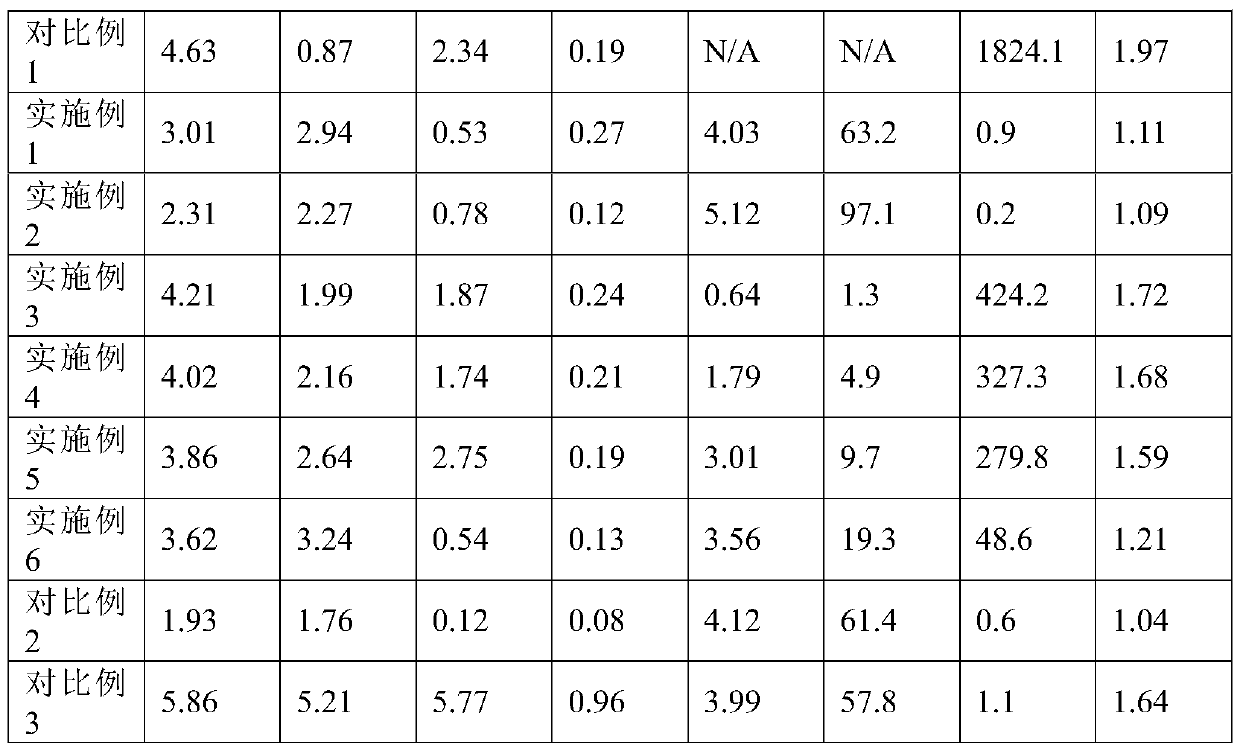

[0158] An all-solid-state lithium battery. The sulfide solid electrolytes obtained in Examples 1 to 6 and Comparative Example 1 are prepared for positive electrode composites, sulfurized solid electrolytes, and negative electrode composites, and are prepared according to [Preparation method of all-solid lithium batteries] The specific parameters of the solid-state lithium battery are shown in Table 3.

[0159] Among them, the positive electrode compound is selected from LiNi corresponding to the sulfide solid electrolyte and the positive electrode active material. 0.6 co 0.2 mn 0.2 o 2 (NCM622) was weighed at a weight ratio of 3:7 and mixed thoroughly in an agate mortar. The negative electrode composite is made by selecting the corresponding sulfide solid electrolyte and graphite as the negative electrode active material at a weight ratio of 1:1, and fully mixing them in an agate mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com