A kind of smoked pepper liquid and its preparation method

A technology of smoked liquid and pepper smoke, which is applied in food science, food preservation, application, etc., can solve the problems of few product types of smoked liquid, limit the development of pepper industry, and singleness, and achieve reduced processing procedures and excellent smoked flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the above-mentioned pepper smoked liquid, comprising the following steps:

[0029] The pretreated pepper is successively subjected to dry distillation, condensation, standing at low temperature and filtering to obtain pepper smoked liquid.

[0030] Specifically, the following steps are included:

[0031] A) destemming, drying and pulverizing the pepper after screening to obtain the pretreated pepper;

[0032] B) the pretreated pepper is dry-distilled to obtain smog;

[0033] C) condensing the smoke to obtain a smoke condensate;

[0034] D) filtering the smoke condensate after standing at low temperature to obtain pepper smoke liquid.

[0035] The present invention uses pepper as a raw material to prepare pepper smoked liquid, wherein the pepper is preferably black pepper.

[0036] In the invention, the pepper is firstly pretreated, and the specific method is as follows: selecting fresh pepper with spikes fr...

Embodiment 1

[0059] The preparation method of smoked liquid is as follows:

[0060] The dried pepper is crushed and sieved to make the particle size 0.2mm, and 40g of pepper powder is weighed and put into a heat-resistant round bottom flask, then heated and cracked in a cracking heating furnace, and then raised to 300°C, and then keep this temperature until the dry distillation is completed, the condensable flue gas produced will be condensed and collected by the condensation system at 10°C, and after the seal is placed in the refrigerator at 4°C for more than 24 hours, stratification will occur, take it out with a Filter with a medium-speed filter paper and a glass funnel, and finally package it in a clean bottle and store it in a refrigerator at 4°C to prevent the flavor from volatilizing.

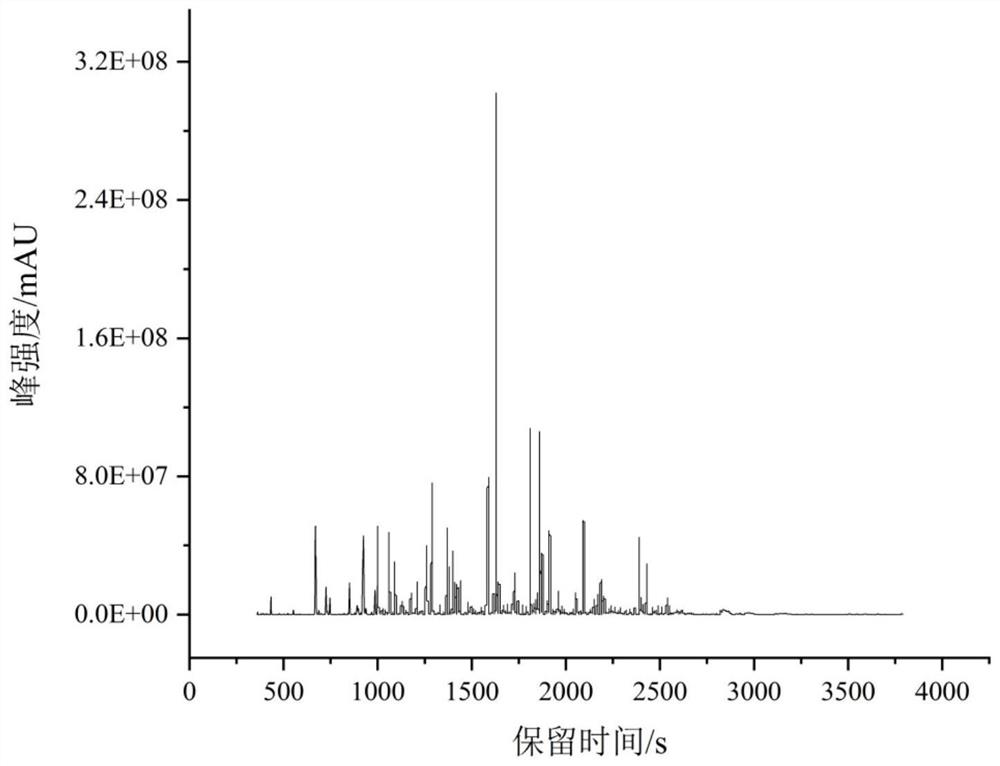

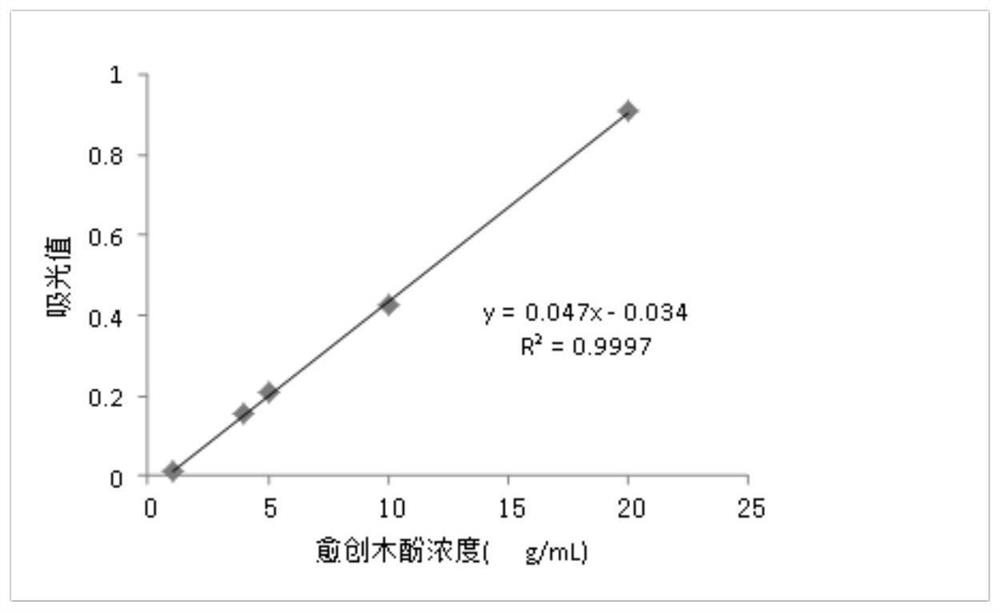

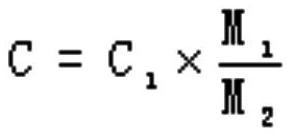

[0061] Carry out the mensuration of phenolic compound and carbonyl compound content to the pepper smoked liquid that obtains, concrete method is as follows:

[0062] 1. Determination of phenolic com...

Embodiment 2

[0082] The preparation method of smoked liquid is as follows:

[0083] The dried pepper is crushed and sieved to make the particle size 1.0mm, and 40g of pepper powder is weighed and put into a heat-resistant round bottom flask, and then heated and cracked in a cracking heating furnace, and then raised to 400°C, then keep this temperature until the dry distillation is completed, the condensable flue gas produced is condensed and collected by the condensation system at 10°C, and after sealing it and placing it in a refrigerator at 4°C for more than 24 hours, stratification will occur, take it out with a Filter with a medium-speed filter paper and a glass funnel, and finally package it in a clean bottle and store it in a refrigerator at 4°C to prevent the flavor from volatilizing.

[0084] According to the method of Example 1, under this condition, the content of phenolic compounds expressed as 2,6-dimethoxyphenol was 2.61 mg / ml, and the content of carbonyl compounds expressed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com