Preparation method and applications of nitrogen-doped copper-palladium bimetal nanometer catalytic material

A technology of bimetallic nano and catalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as poor stability and poor dispersion, achieve high stability, improve dispersion, Good dispersion and stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

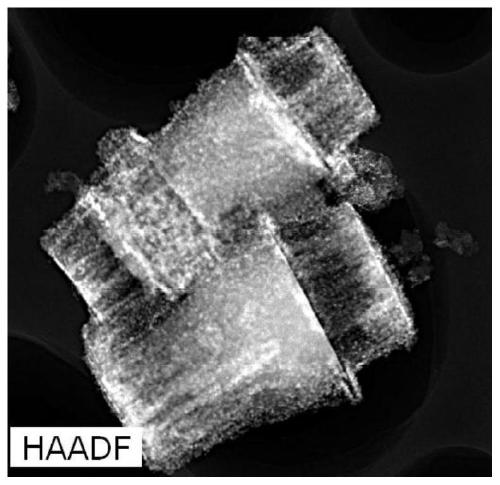

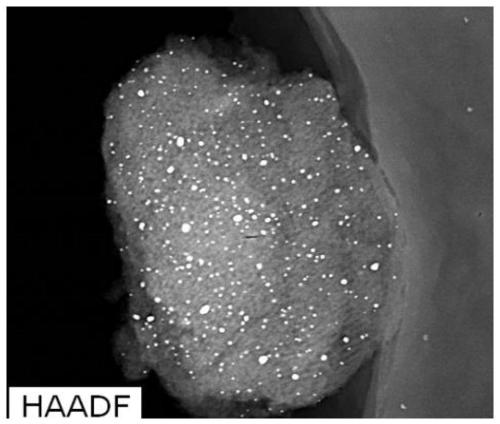

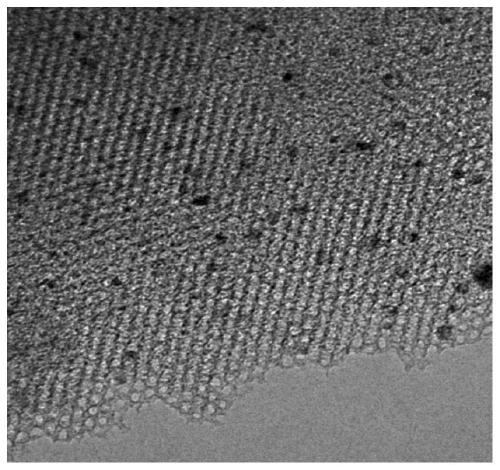

Image

Examples

Embodiment 1

[0027] 1. The preparation of nitrogen-doped copper-palladium bimetallic nanocatalytic materials, the specific steps are as follows:

[0028] (1) Put copper nitrate (1.5mol) and palladium acetylacetonate (0.38mol) in 1.5mL N,N-dimethylformamide (DMF), mix well to form a uniform dispersion system, in this uniform dispersion system Add the organic ligand triethylenediamine (nitrogen source, 4.58mol) and terephthalic acid (4.35mol) for hydrothermal reaction, mix and stir for about 30min, move to the hydrothermal reactor and react at 150°C for 12h to prepare N-Cu-PdMOFs were obtained.

[0029] (2) Add the N-Cu-PdMOFs and OMC (150mg) prepared in step (1) into DMF and sonicate for about 30min, then move the mixture to a hydrothermal reactor for 16h at 180°C; wash the obtained product, After centrifugation, place at 140°C for vacuum drying for 6 hours;

[0030] (3) After the product obtained in step (2) was pyrolyzed at 600 °C for 2 h in a tube furnace in an argon (90 mL / min) atmosp...

Embodiment 2

[0041] The preparation of nitrogen-doped copper-palladium bimetallic nanocatalytic material and the method of catalytic reduction of nitrate are as in Example 1, the difference is that the mass ratio of copper-palladium is controlled when preparing nitrogen-doped space-confined N-Cu-Pd@OMC The ratio is 2:1, the high temperature pyrolysis time is 1h under nitrogen atmosphere, and after 24h of electrocatalytic reaction, the nitrogen selectivity is 84%, and the nitrate removal capacity is 493.6mgN / g catalyst.

Embodiment 3

[0043] The preparation of nitrogen-doped copper-palladium bimetallic nanocatalytic material and the method of catalytic reduction of nitrate are as in Example 1, the difference is that the calcination temperature adopted when preparing nitrogen-doped space-confined N-Cu-Pd@OMC catalyst is 800°C, the nitrate concentration of this system is 200ml, the coating amount of nano-catalyst material is 5mg, the area of nickel mesh is 2cm×2.5cm, after electrocatalytic reaction for 30h, the selectivity of nitrogen is 86%, and the removal capacity of nitrate It is 1273.6mgN / g catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com