Silver electrode activating method

An activation method, silver electrode technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve the problems of low surface area of three-dimensional porous structure, easy collapse of three-dimensional porous structure, low removal rate of miscellaneous metals, etc. The effect of improving dechlorination activity and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the activation method of bright silver electrode

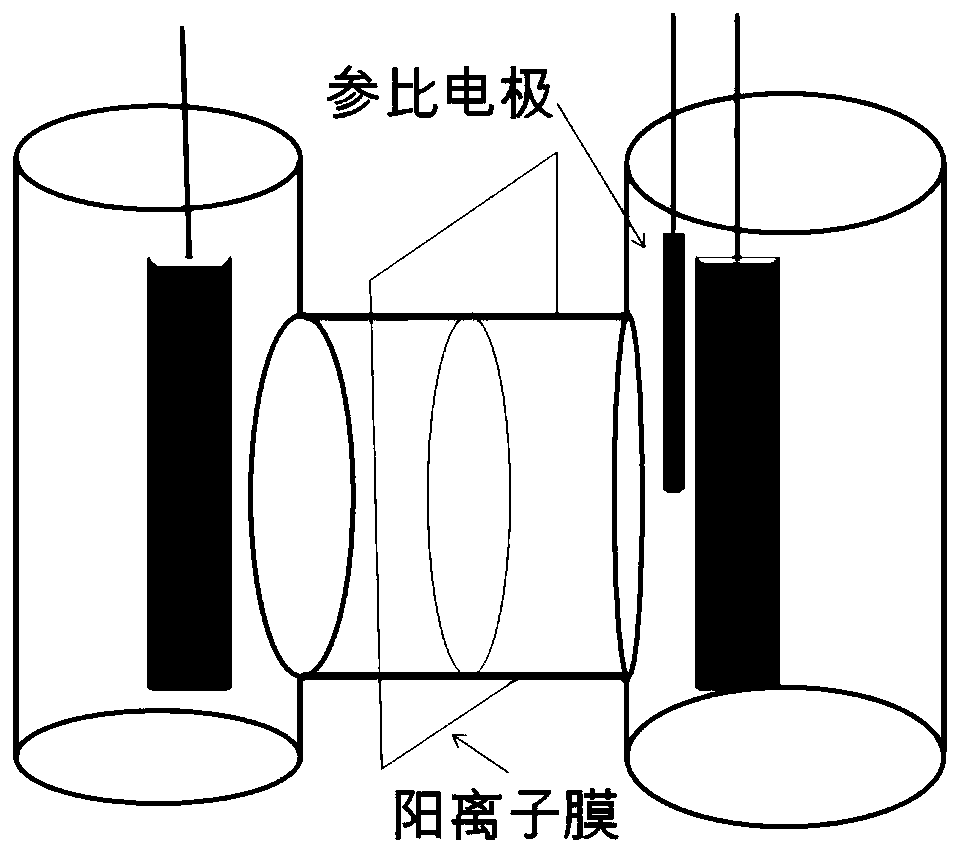

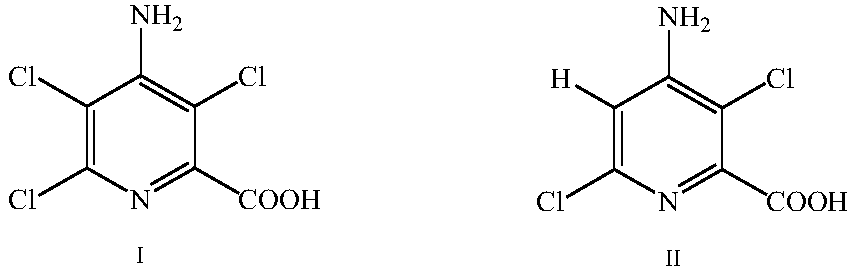

[0034] (1) Redox of acid solution: in H-type cationic membrane electrolyzer with Nafion 117 cationic membrane (such as figure 1Shown), bright silver sheet (purity is 99.9wt%, size is 0.1cm * 2.0cm * 2.0cm) is working electrode; Platinum sheet of the same area is counter electrode; Silver / silver chloride is reference electrode. The working electrode chamber is a 10wt% hydrochloric acid aqueous solution (referred to as 1# electrolyte), and the counter electrode chamber is a 1.0mol / L sodium hydroxide aqueous solution. Control the temperature of the aqueous hydrochloric acid solution at 20-25°C, first apply a current density of 0.5A / dm to the silver electrode 2 The anodizing current until the electrode potential reaches +0.7vs.SHE; then reverse the current (with the silver sheet as the counter electrode and the platinum sheet as the working electrode), and apply a current density of 0.5A / dm to the silver elec...

Embodiment 2-7

[0037] According to the method of embodiment 1, change 1# electrolytic solution and 2# electrolytic solution in embodiment 1, redox current density, redox cut-off potential and reaction temperature into table 1, and the activated silver roughness prepared is shown in table 1 .

[0038] Table 1 Experimental parameters and roughness of activated silver electrode

[0039]

Embodiment 8

[0044] Embodiment 8: the electrochemical dechlorination of dichloromethane (silver electrode is not activated in the middle of the batch reaction)

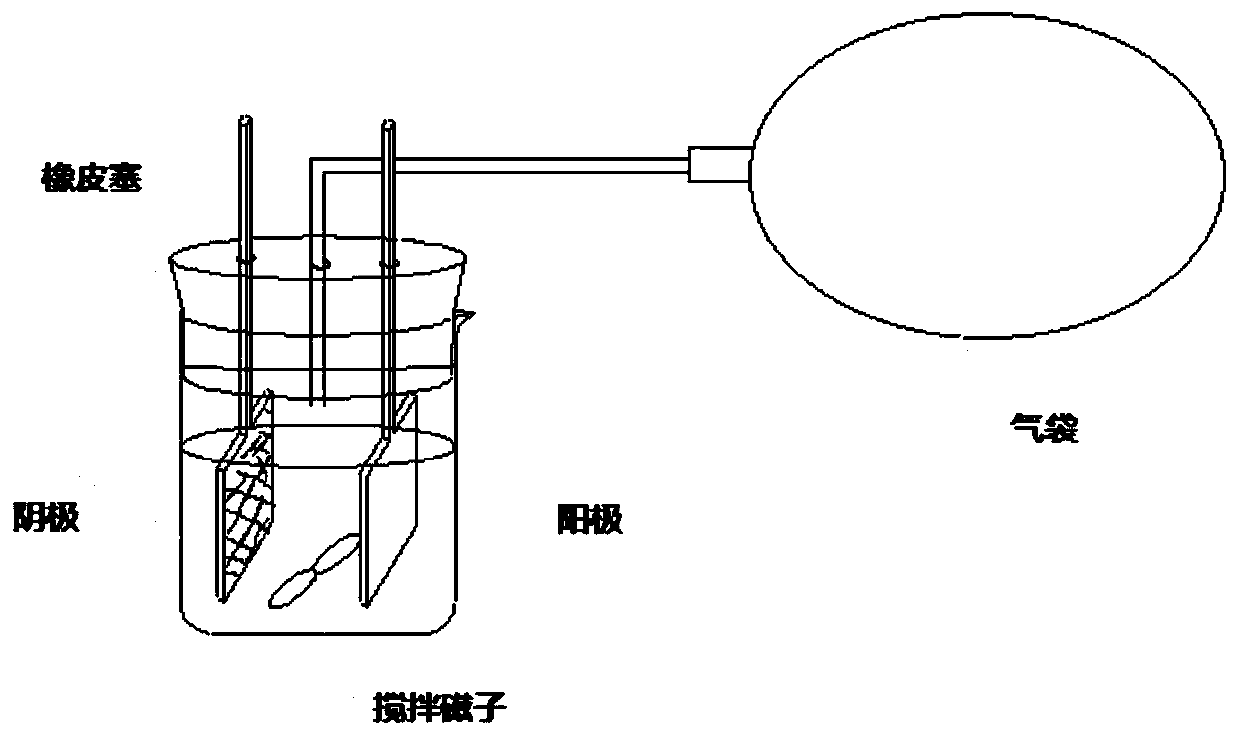

[0045] Sealed diaphragmless electrolyzers with air pockets (e.g. figure 2 Shown), the activated silver electrode (geometric dimension is 0.1cm * 2.0cm * 2.0cm, purity is 99.9wt%) prepared by the method described in Example 1 is the negative electrode, and the magnesium plate of the same area (geometric dimension is 0.3cm ×2.0cm×2.0cm) is the anode; 50mL of acetonitrile solution containing 0.1mol / L tetrabutylammonium perchlorate+5wt% acetic acid+20mmol / L dichloromethane is the electrolyte. At 25-30°C, feed 1A / dm 2 After 4 hours of reaction, the electrolysis was stopped. The yield of methane determined by gas chromatography is: 98%; the conversion rate of dichloromethane is 100%.

[0046] After repeating the above-mentioned electrochemical dechlorination process of dichloromethane 5 times, the roughness of the activated silver e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com