Method for in-situ preparation of nickel-iron bimetallic materials by repairing nickel ion polluted wastewater

An in-situ preparation, bimetallic technology, applied in water pollutants, metal processing equipment, water/sewage treatment, etc., to achieve the effects of low energy consumption, fast speed, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) in N 2 Under protection, 0.5g / L sodium bentonite, 0.05mol / L FeSO 4 ·7H 2 O and 0.1mol / L NaBH 4 Mix and stir for 2 hours, wash with deoxygenated water and ethanol, and vacuum freeze-dry to prepare bentonite-supported nanometer zero-valent iron.

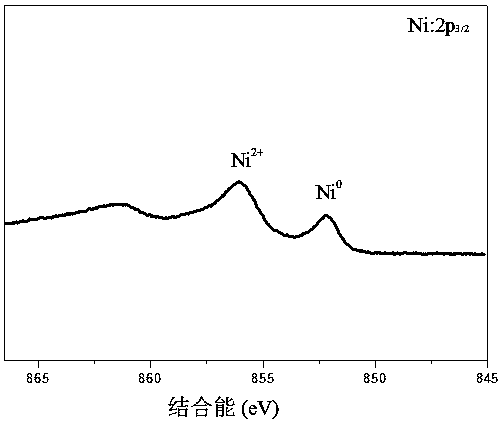

[0030] (2) Weigh the bentonite loaded with zero-valent iron (25 mg iron content) prepared in step (1) and add it to the wastewater containing 200 mg / L Ni(II) (adjust the pH to 6). in N 2 Under protection, shake the reaction for 2 hours (150 rpm, 25°C). After the reaction, the solid was obtained by centrifugation, and the residual Ni(II) in the supernatant was determined to be zero, and the removal rate of Ni(II) was 100%. The solid was washed, vacuum freeze-dried, and determined by XPS to contain zero-valent nickel active components such as figure 1 As shown, the results confirm that the Fe / Ni(II) bimetal was indeed formed during the treatment of Ni(II) with zero-valent iron loaded on bentonite.

[0031] (3) Add the N...

Embodiment 2

[0033] (1) Bentonite loaded with zero-valent iron was prepared according to the method of step (1) in Example (1).

[0034](2) Weigh the bentonite loaded with zero-valent iron (15 mg iron content) prepared in step (1) and add it to the waste water containing 100 mg / L Ni(II) (adjust the pH to 5). 2 Under protection, shake the reaction for 2 hours (150 rpm, 25°C). After the reaction, the Ni / Fe bimetallic material was obtained by centrifugation, and the residual Ni(II) in the supernatant was determined to be zero, and the removal rate of Ni(II) was 100%.

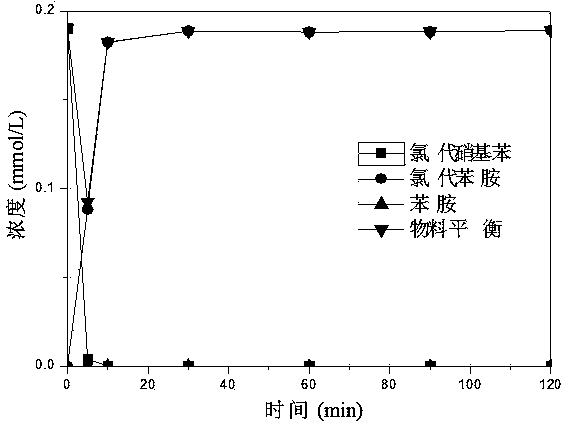

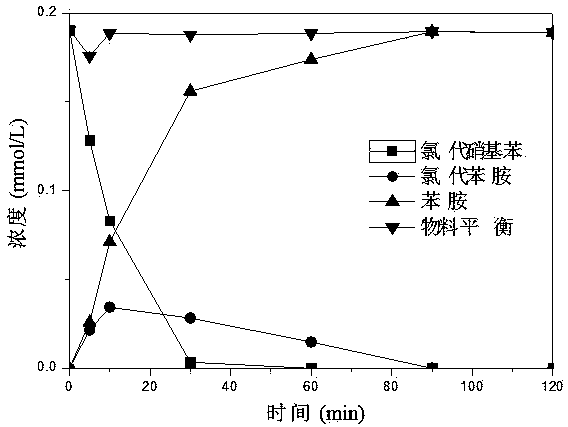

[0035] (3) Add the Ni / Fe bimetallic material obtained in step (2) and the Ni / Fe bimetallic material prepared by conventional methods (the iron content of the two materials are the same), respectively, into Benzene wastewater (pH 6), N 2 Shake the reaction under protection for 2 hours (150 rpm, 25°C). After the reaction, the products and their concentrations in the wastewater were measured respectively. The results showed th...

Embodiment 3

[0037] (1) Bentonite loaded with zero-valent iron was prepared according to the method of step (1) in Example (1).

[0038] (2) Weigh the bentonite loaded with zero-valent iron (10 mg iron content) prepared in step (1) and add it to the wastewater containing 50 mg / L Ni(II) (adjust the pH to 6.5). 2 Under protection, shake the reaction for 1 hour (150 rpm, 25°C). After the reaction, the Ni / Fe bimetallic material was obtained by centrifugation, and the residual Ni(II) in the supernatant was determined to be zero, and the removal rate of Ni(II) was 100%.

[0039] (3) Add the Ni / Fe bimetallic material obtained in step (2) to the wastewater containing 20 mg / L p-chlorophenol (pH 6), N 2 Shake the reaction under protection for 2 hours (150 rpm, 25°C). After the reaction, the products and their concentrations in the wastewater were measured respectively. The results show that the Ni / Fe bimetallic material has completely reduced p-chlorophenol to phenol, indicating that the chlorine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com