A kind of gas phase dechlorination agent and preparation method thereof

A gas phase dechlorination and mixture technology, which is applied in separation methods, chemical instruments and methods, gas treatment and other directions to achieve the effects of improving dechlorination performance, expanding the scope of application, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

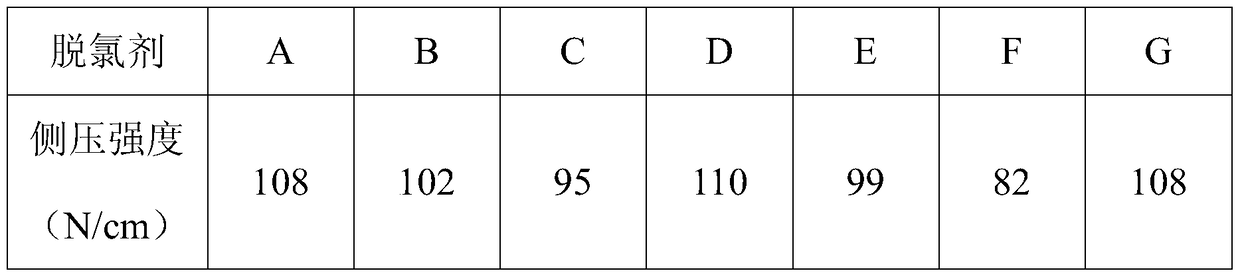

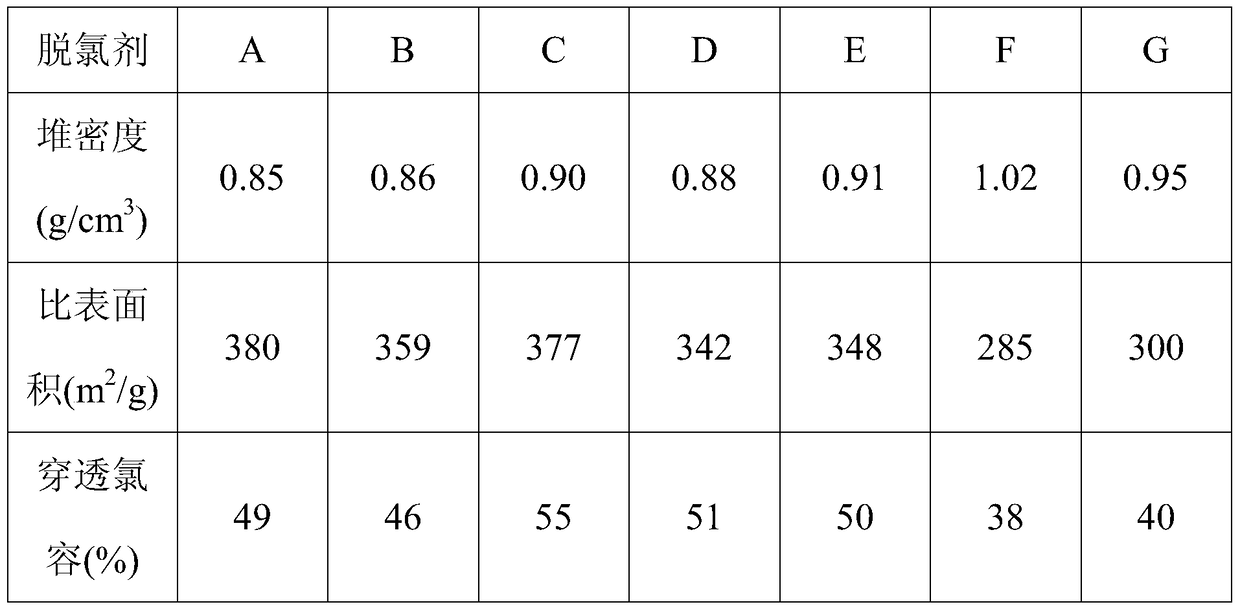

Examples

Embodiment 1

[0030] (1) polyvinyl alcohol is dissolved in water, is mixed with 6wt% polyvinyl alcohol aqueous solution, for subsequent use;

[0031] (2) Calcium acetate is dissolved in water, is mixed with 8wt% calcium acetate aqueous solution, for subsequent use;

[0032] (3) Mix aluminate cement with polyvinyl alcohol aqueous solution, and then mix with magnesium carbonate with a particle size of 1-10nm to form the first mixture; wherein, the amount of polyvinyl alcohol aqueous solution is aluminate cement 35% by weight of mass;

[0033] (4) Calcium hydroxide and calcium acetate aqueous solution are mixed to form the second mixture, and the add-on of calcium acetate aqueous solution is 25wt% of calcium hydroxide quality;

[0034] (5) mixing the first mixture of step (3) with the second mixture of step (4) to form a third mixture, and extruding the third mixture to obtain strips of Φ4mm;

[0035] (6) Put the strip in step (5) to calcine at 290°C for 5 hours, and then calcine the roasted...

Embodiment 2

[0038] (1) polyvinyl alcohol is dissolved in water, is mixed with 2wt% polyvinyl alcohol aqueous solution, for subsequent use;

[0039] (2) Calcium acetate is dissolved in water, is mixed with 5.5wt% calcium acetate aqueous solution, for subsequent use;

[0040] (3) Mix aluminate cement with polyvinyl alcohol aqueous solution, and then mix with magnesium carbonate with a particle size of 1-10nm to form the first mixture; wherein, the amount of polyvinyl alcohol aqueous solution is aluminate cement 50% by weight of mass;

[0041] (4) Calcium hydroxide and calcium acetate aqueous solution are mixed to form the second mixture, and the addition of calcium acetate aqueous solution is 20wt% of calcium hydroxide quality;

[0042] (5) mixing the first mixture of step (3) with the second mixture of step (4) to form a third mixture, and extruding the third mixture to obtain strips of Φ4mm;

[0043] (6) The strip in step (5) was calcined at 200° C. for 6 hours, and then the calcined pr...

Embodiment 3

[0046] (1) polyvinyl alcohol is dissolved in water, is mixed with 10wt% polyvinyl alcohol aqueous solution, for subsequent use;

[0047] (2) Calcium acetate is dissolved in water, is mixed with 3wt% calcium acetate aqueous solution, for subsequent use;

[0048] (3) Mix aluminate cement with polyvinyl alcohol aqueous solution, and then mix with magnesium carbonate with a particle size of 1-10nm to form the first mixture; wherein, the amount of polyvinyl alcohol aqueous solution is aluminate cement 20 wt% of the mass;

[0049] (4) calcium hydroxide, ferric oxide and calcium acetate aqueous solution are mixed to form the second mixture, wherein, the add-on of ferric oxide is 1.6wt% of calcium hydroxide quality, the add-on of calcium acetate aqueous solution is 30wt% of the mass sum of calcium and ferric oxide;

[0050] (5) mixing the first mixture of step (3) with the second mixture of step (4) to form a third mixture, and extruding the third mixture to obtain strips of Φ4mm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com