Processing technology of egg roll type crispy tilapia skin

A processing technology and fish skin technology, which is applied in the direction of food ingredients as taste improvers, food ingredients as coating agents, food science, etc., can solve the problems of single appearance and inconvenient eating of crispy fish skin products, and achieve a good eating experience , Easy to eat directly, loose texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

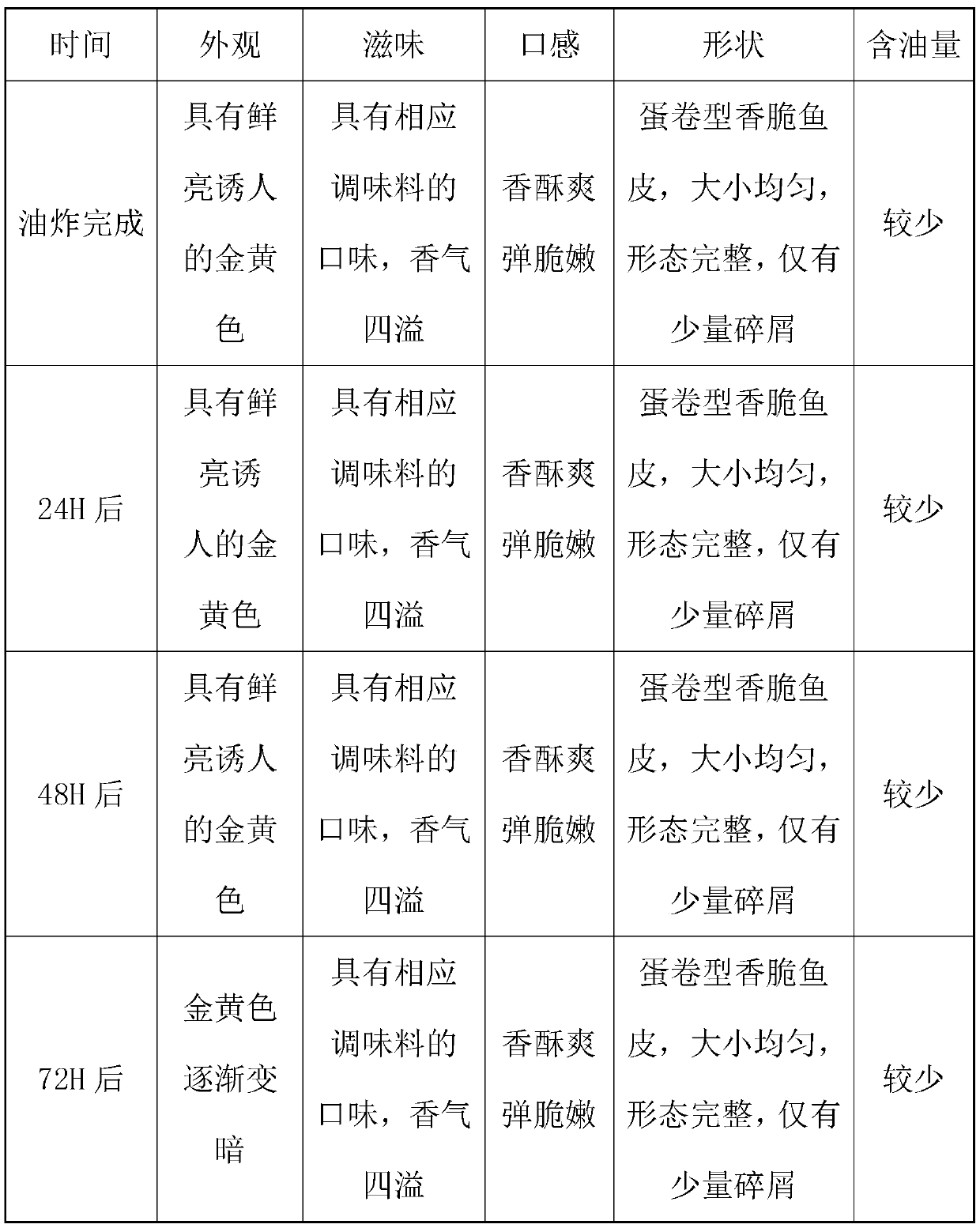

Examples

Embodiment 1

[0035] Embodiment 1: This embodiment provides an egg roll type crispy fish skin processing technology, which is carried out according to the following process steps:

[0036] S1. Raw material pretreatment: the frozen and stored crispy tilapia skin is thawed, descaled, washed, and drained to obtain clean and dry crispy tilapia skin, and then cut to 10-12cm wide and 7 ~9cm flakes, considering that the fish skin will shrink during the subsequent air-drying and frying process, so when the fish skin is cut into flakes, keep a certain size, and the ambient temperature in the operation room should be 5-15℃ , In order to avoid the breeding of bacteria and other microorganisms in the operation room that harm food safety.

[0037] S2, marinating seasoning: marinate the sliced fish skin cut in step S1 with marinating seasoning to remove the fishy smell of the fish skin. The marinating can also make the fish skin soak in enough seasonings to make the fish skin have A certain amount of salt;...

Embodiment 2

[0043] Embodiment 2: Most of the content of this embodiment is basically the same as that of Embodiment 1, the difference is that the hot air drying in step S3 is replaced by roll-type drying: that is, the fish skin marinated in step S2 is heated in a high-pressure steam cooker Steamed at 80~160℃ for 20~40 minutes, then use a cylindrical mold to roll the steamed fish skin into an egg roll shape fish skin instead of using an egg roll forming machine to roll it into an egg roll shape and then roll it into The egg roll-shaped fish skin is placed in a drying box at 80-120°C and dried until the water content of the fish skin is 10%-25%, and then taken out for use. Through steaming, the surface of the fish skin is partially steamed, which is convenient for expansion during frying and puffing. It is first rolled into egg roll-shaped fish skin and then dried so that the surface of the egg roll-shaped fish skin can be fully impregnated with a layer of edible oil during the oil immersion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com