A kind of processing method of high temperature resistant titanium alloy casting

A processing method and titanium alloy technology, applied in the preparation/treatment of rare earth metal compounds, rare earth metal oxides/hydroxides, yttrium oxide/yttrium hydroxide, etc., can solve the problem of poor fluidity of titanium alloy materials and decline in mechanical properties of products , Insufficient compactness and other problems, to achieve the effect of good casting surface quality, improved mechanical properties, improved use safety and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

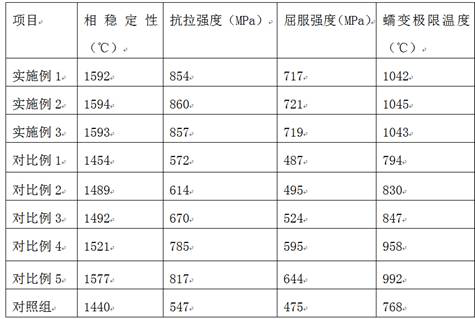

Examples

Embodiment 1

[0019] A processing method for a high temperature resistant titanium alloy casting, comprising the following steps:

[0020] (1) Clean and dry the titanium alloy ingot and place it in a graphite crucible resistance furnace for smelting. After the ingot is completely melted, add nano-yttrium oxide powder with a mass fraction of 0.037% of the ingot mass, and refine after slight stirring , stand still for 4 minutes after deoxygenation and degassing, and remove slag;

[0021] (2) After cooling the alloy liquid after slag removal for 8 seconds, squeeze it into the cavity of the device mold after preheating and exhausting at 310°C. Under the operation of the squeeze casting equipment, pressurize the mold and apply a pressure of 1800KN. The holding time is 34 seconds, and the initial extrusion speed is 0.04 m / s. After maintaining for 10 seconds, keep moving at a speed of 0.12 m / s. After the alloy liquid is completely solidified, open the mold and pick up the parts.

[0022] As a fur...

Embodiment 2

[0030] A processing method for a high temperature resistant titanium alloy casting, comprising the following steps:

[0031] (1) Clean and dry the titanium alloy ingot and place it in a graphite crucible resistance furnace for smelting. After the ingot is completely melted, add nano-yttrium oxide powder with a mass fraction of 0.038% of the ingot mass, and refine after slight stirring , stand still for 5 minutes after deoxygenation and degassing, and remove slag;

[0032] (2) After cooling the alloy liquid after slag removal for 9 seconds, squeeze it into the cavity of the device mold after preheating and exhausting at 320°C. Under the extrusion casting equipment, pressurize the mold and apply a pressure of 1820KN. The holding time is 36 seconds, and the initial extrusion speed is 0.045 m / s. After maintaining for 11 seconds, keep moving at a speed of 0.13 m / s. After the alloy liquid is completely solidified, the mold can be opened and the parts can be taken.

[0033] As a fur...

Embodiment 3

[0041] A processing method for a high temperature resistant titanium alloy casting, comprising the following steps:

[0042] (1) Clean and dry the titanium alloy ingot and place it in a graphite crucible resistance furnace for smelting. After the ingot is completely melted, add nano-yttrium oxide powder with a mass fraction of 0.040% of the ingot mass, and refine after slight stirring , stand still for 6 minutes after deoxygenation and degassing, and carry out slag removal;

[0043] (2) After cooling the alloy liquid after slag removal for 10 seconds, squeeze it into the cavity of the device mold after preheating and exhausting at 330°C. Under the operation of the extrusion casting equipment, pressurize the mold and apply a pressure of 1840KN. The holding time is 38 seconds, and the initial extrusion speed is 0.05 m / s. After maintaining for 12 seconds, keep moving at a speed of 0.14 m / s. After the alloy liquid is completely solidified, the mold can be opened and the parts can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com