Spirobifluorene conjugated microporous polymer/carbon nanotube hybrid material and preparation method thereof

A technology of conjugated micropores and carbon nanotubes, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of poor conductivity and poor cycle stability, and achieve the effects of simple operation, increased cycle stability, and improved cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] First, 2,2'-7,7'-tetrabromo-9,9'-spirobifluorene (252.8mg, 0.4mmoL), p-phenylenediamine (88.6mg, 0.8mmoL), Pd(dba) 2 (18.4mg, 0.032mmoL), XPhos (23.3mg, 0.048mmoL), sodium tert-butoxide (204.3mg, 2.128mmoL) were placed in a 100mL Schlenk tube, vacuum-backfilled with Ar gas three times, followed by adding 50mL of toluene solvent; Then, the reaction device was reacted at 110°C for 48h. After the end, suction filtration was performed in a sand core funnel, followed by washing with DMF, methanol, and chloroform for 12h each, and finally drying in a vacuum oven at 60°C for 24h. The obtained spirobifluorene conjugated organic polymer powder is denoted as PSPDF.

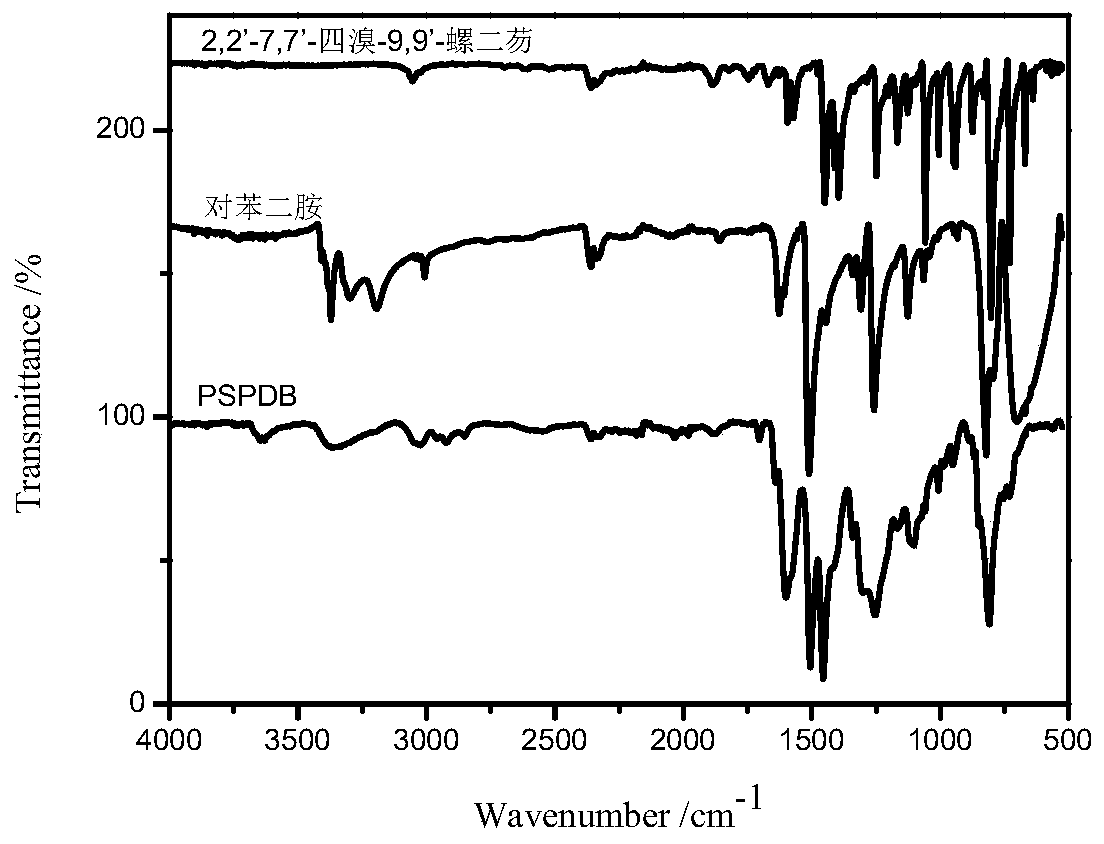

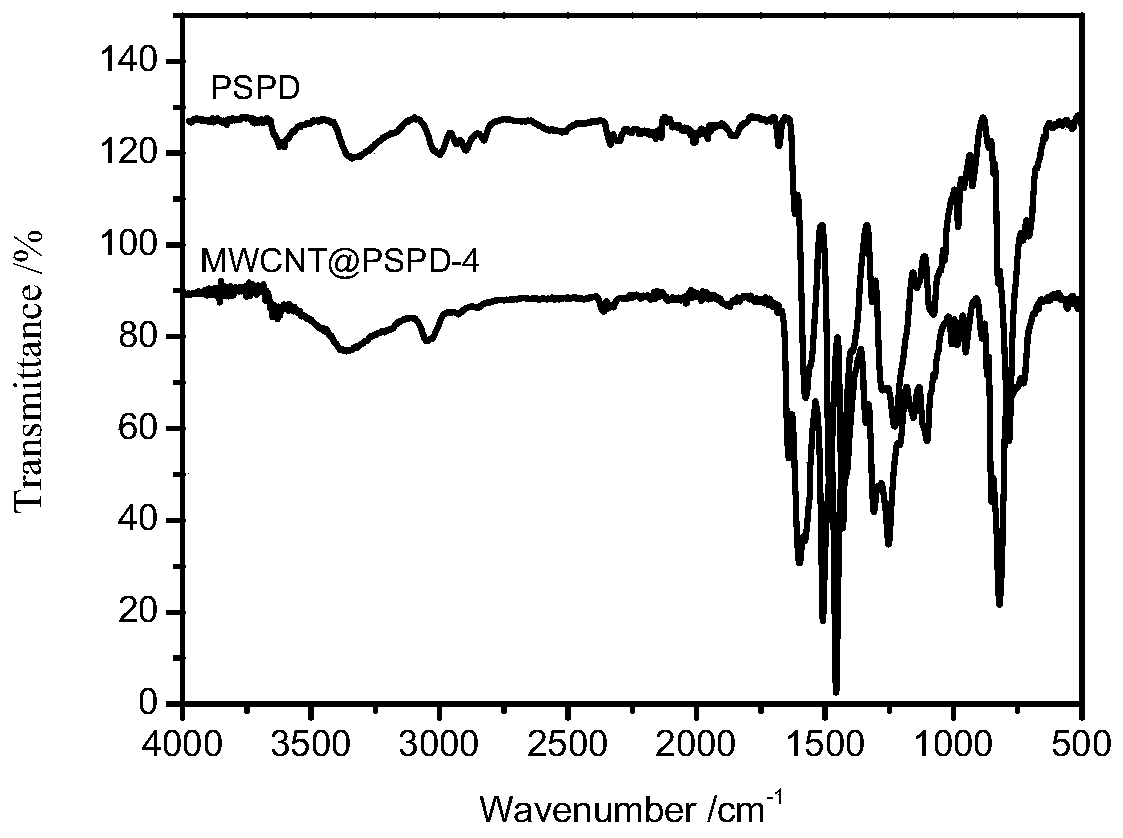

[0046]The infrared test results of PSPDF obtained in this example and 2,2'-7,7'-tetrabromo-9,9'-spirobifluorene and p-phenylenediamine are as follows figure 1 As shown, it can be seen that the C-Br on the aromatic ring in 2,2'-7,7'-tetrabromo-9,9'-spirobifluorene is at 532cm -1 and 1079cm -1 There is a stretching...

Embodiment 2

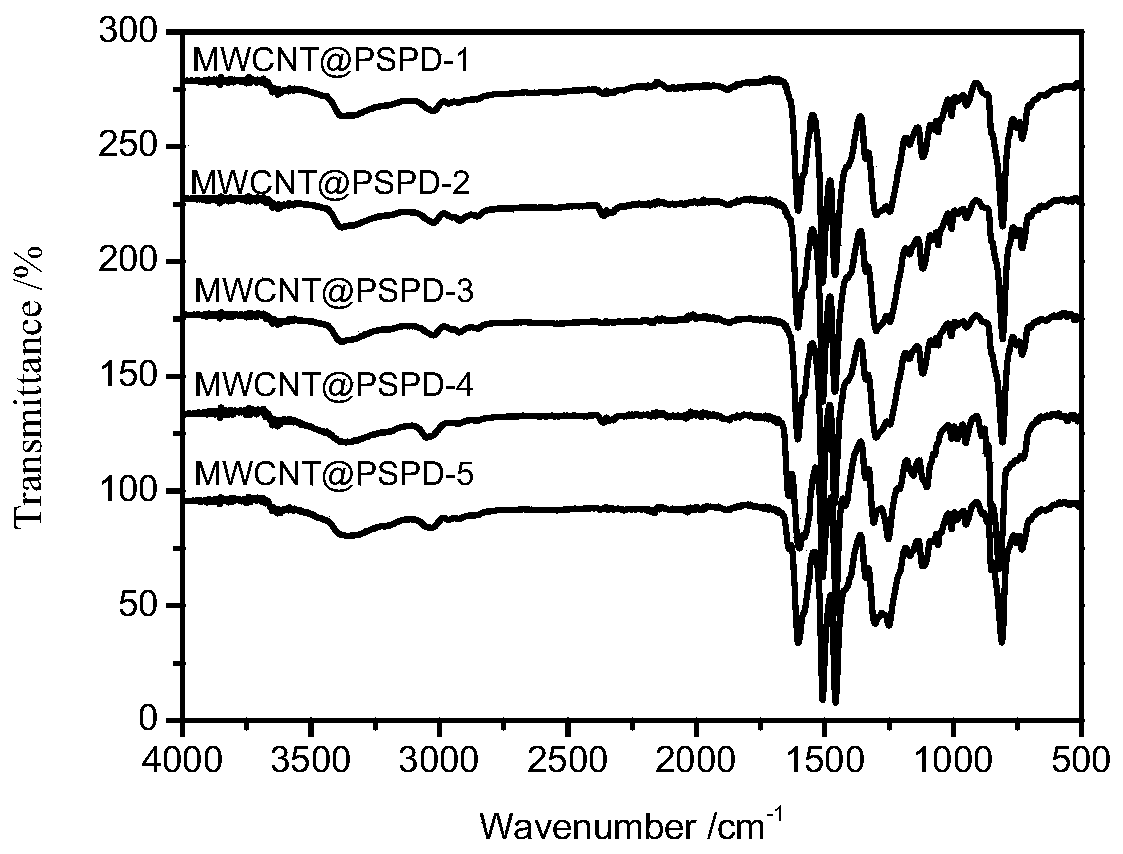

[0050] First, 2,2'-7,7'-tetrabromo-9,9'-spirobifluorene (252.8mg, 0.4mmoL), p-phenylenediamine (88.6mg, 0.8mmoL), Pd(dba) 2 (18.4mg, 0.032mmoL), XPhos (23.3mg, 0.048mmoL), sodium tert-butoxide (204.3mg, 2.128mmoL) were placed in a 100mL Schlenk tube, vacuum-backfilled with Ar gas three times, and then aminated poly 0.5% (1mg) wall carbon nanotubes were ultrasonically dispersed in toluene (50mL), and at the same time, the dispersed carbon nanotubes were added into the Schlenk tube, and stirred at room temperature for 0.5h, so that the carbon nanotubes were well dispersed in the polymerization system; then, The reaction device was reacted at 110°C for 48h. After the end, suction filtration was carried out in a sand core funnel, and then washed with DMF, methanol, and chloroform respectively for 12h each, and finally dried in a vacuum oven at 60°C for 24h. The obtained spirobifluorene conjugated microporous polymer / carbon nanotube hybrid material powder is denoted as MWCNT@PSPD-1...

Embodiment 3

[0053] First, 2,2'-7,7'-tetrabromo-9,9'-spirobifluorene (252.8mg, 0.4mmoL), p-phenylenediamine (88.6mg, 0.8mmoL), Pd(dba) 2 (18.4mg, 0.032mmoL), XPhos (23.3mg, 0.048mmoL), sodium tert-butoxide (204.3mg, 2.128mmoL) were placed in a 100mL Schlenk tube, vacuum-backfilled with Ar gas three times, at the same time, aminated poly Wall carbon nanotubes 2% (4mg) were ultrasonically dispersed in toluene (50mL). Secondly, the dispersed carbon nanotubes were added into the Schlenk tube, and stirred at room temperature for 0.5h, so that the carbon nanotubes were well dispersed in the polymerization system; then, The reaction device was reacted at 110°C for 48h. After the end, suction filtration was carried out in a sand core funnel, and then washed with DMF, methanol, and chloroform respectively for 12h each, and finally dried in a vacuum oven at 60°C for 24h. The obtained spirobifluorene conjugated microporous polymer / carbon nanotube hybrid material powder is denoted as MWCNT@PSPD-2.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com