Nano ground calcium carbonate specially used for special cable

A heavy calcium carbonate, special cable technology, applied in inorganic pigment treatment, dyeing physical treatment, dyeing low molecular organic compound treatment, etc. performance requirements and other issues to achieve the effect of improving the use effect and avoiding the increase in particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

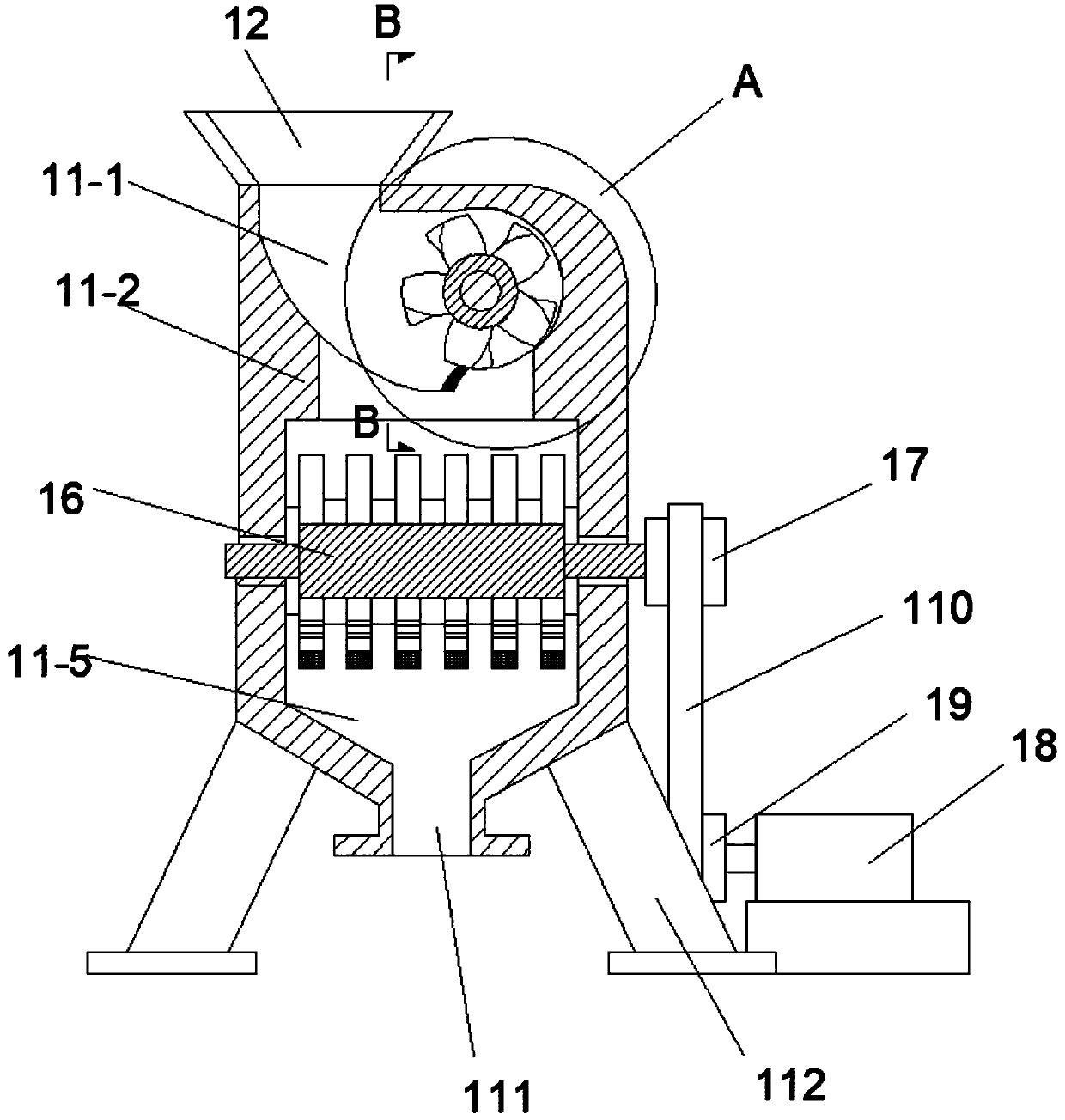

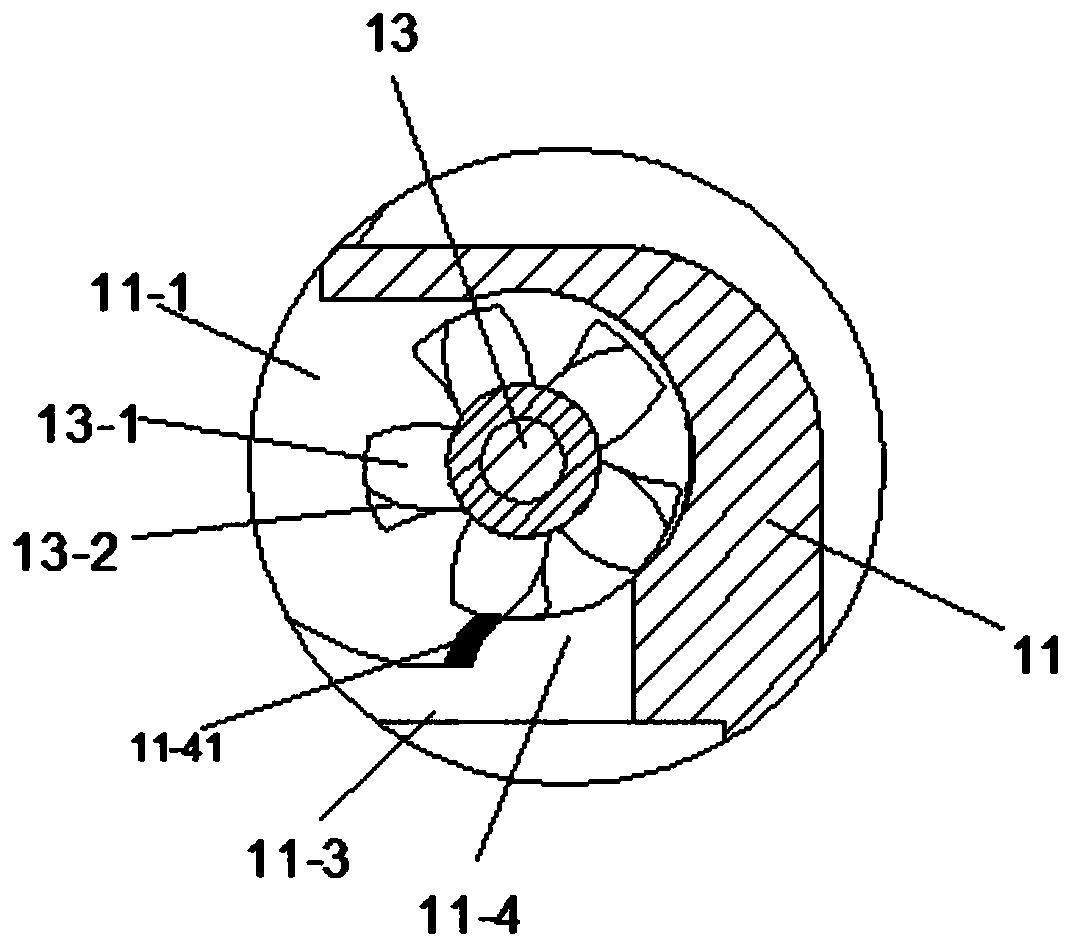

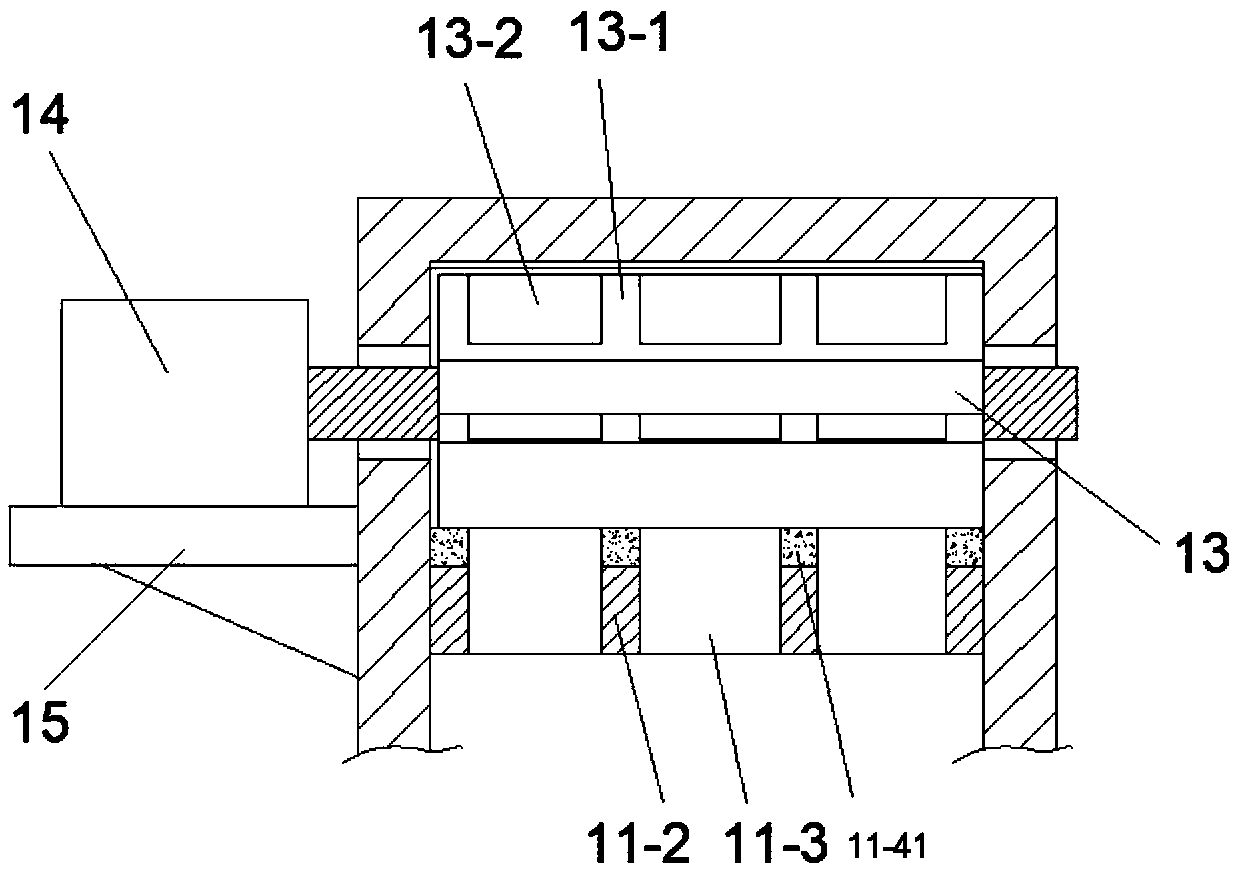

[0053] A special nano heavy calcium carbonate for special cables, characterized in that the preparation method is as follows,

[0054] (1) Limestone pretreatment, put the limestone crushed material into a crushing device for crushing, the crushing time is 20-40min, after crushing, the limestone material becomes 30 mesh powder, and the limestone pretreatment is completed;

[0055] (2) beating, in parts by mass, 88 parts of limestone, 37 parts of water, and 7 parts of dispersant are fully mixed and stirred, the mixing speed is 100r / min, and the mixing time is 77min, and the mixing is completed to obtain a slurry;

[0056] (3) Grinding, the mixed slurry is wet-ground, the flow rate of the slurry is 6t / h, and a dispersant is added during the grinding process, the grinding temperature is 33°C, and the grinding time is 74min;

[0057] (4) Grinding for the second time, grind the slurry for the first time again, the flow rate of the slurry is 6t / h, and a dispersant is added during the...

Embodiment 2

[0092] Compared with embodiment 1, the differences of this embodiment are:

[0093] A special nano heavy calcium carbonate for special cables, characterized in that the preparation method is as follows,

[0094] (1) Limestone pretreatment, the limestone crushed material is placed in the crushing device for crushing, the crushing time is 20min, the limestone material after crushing becomes 20 mesh powder, and the limestone pretreatment is completed;

[0095] (2) beating, in parts by mass, 90 parts of limestone, 33 parts of water, and 6 parts of dispersant are fully mixed and stirred, the mixing speed is 100r / min, and the mixing time is 40min, and the mixing is completed to obtain a slurry;

[0096] (3) Grinding, the mixed slurry is wet-ground, the flow rate of the slurry is 6t / h, and a dispersant is added during the grinding process, the grinding temperature is 30°C, and the grinding time is 70min;

[0097] (4) Secondary grinding, grind the slurry for the first time again, the...

Embodiment 3

[0103] Compared with embodiment 1, the differences of this embodiment are:

[0104] A special nano heavy calcium carbonate for special cables, characterized in that the preparation method is as follows,

[0105] (1) Limestone pretreatment, the limestone crushed material is placed in the crushing device for crushing, the crushing time is 40min, the limestone material after crushing becomes 40 mesh powder, and the limestone pretreatment is completed;

[0106] (2) beating, in parts by mass, 85 parts of limestone, 40 parts of water, and 8 parts of dispersant are fully mixed and stirred, the mixing speed is 100r / min, and the mixing time is 80min, and the mixing is completed to obtain a slurry;

[0107] (3) Grinding, the mixed slurry is wet-ground, the flow rate of the slurry is 6t / h, and a dispersant is added during the grinding process, the grinding temperature is 45°C, and the grinding time is 80min;

[0108] (4) Grinding for the second time, grind the slurry for the first time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com