Method for constructing antifouling-sterilizing-releasing type surface coating by utilizing dopamine and product thereof

A technology of surface coating and dopamine, which is applied in the field of polymer coating preparation, can solve the problems of complex preparation methods of polymer brushes and single application substrate, achieve long-term anti-bacterial adhesion and kill bacteria, realize functional regeneration, Avoid complex effects with compositing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

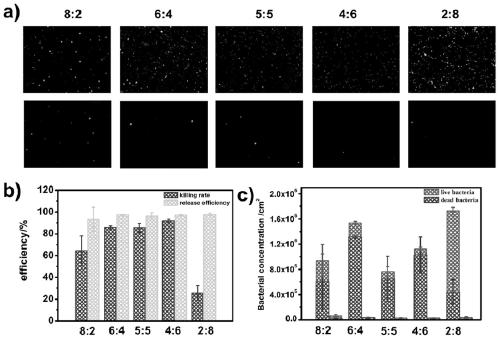

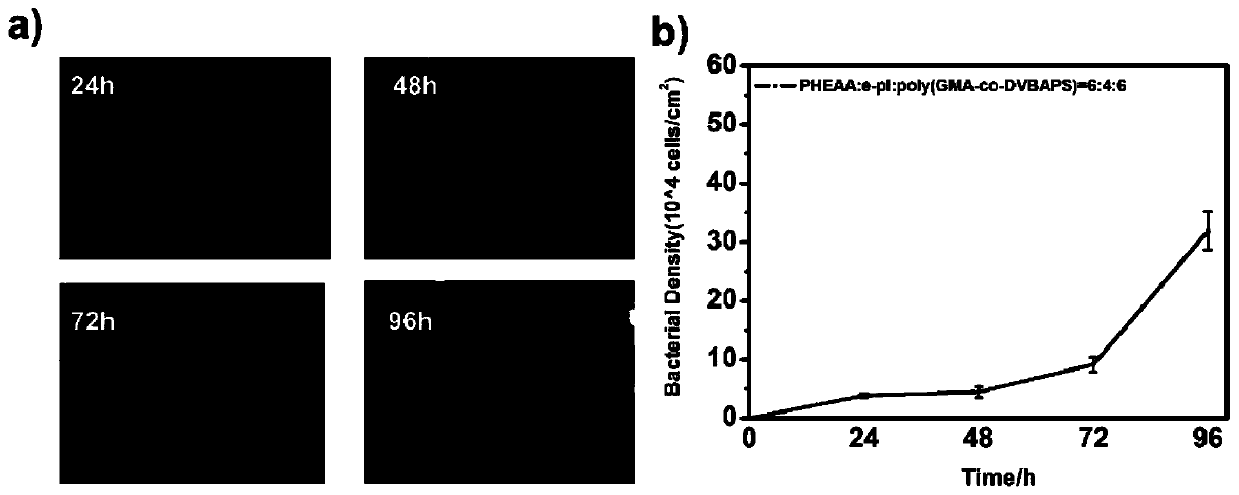

[0032] (1) Take a 50ml round bottom beaker, and add 0.57g of 3-(dimethyl(4-vinylbenzyl)amino)propanesulfonate (DVBAPS) and 0.07g of glycidyl methacrylate (GMA) to it in sequence With the mixed solvent (V:V=1:1) of 2.5ml trifluoroethanol and deionized water, stir 10 minutes and mix homogeneously, then add 0.004g initiator AIBN and stir for 15 minutes, then carry out nitrogen blowing for 15 minutes, then Place it in a water bath at 60°C for 6 hours. After the reaction is over, open the reaction flask and place it in an ice-water bath, then pour the reaction product into an ethanol solution, centrifuge and purify the precipitated polymer, and finally dry it in a vacuum oven to obtain Transparent polymer poly(GMA-co-DVBAPS).

[0033] (2) Weigh 0.06g dopamine hydrochloride and add 30ml Tris-HCl buffer solution, then add 0.18g poly(GMA-co-DVBAPS), 0.12g polylysine and 0.12g poly N-(2-hydroxyethyl) Acrylamide (pHEAA) was finally placed on a glass slide and co-deposited at room tempe...

Embodiment 2

[0035] (1) Take a 50ml round bottom beaker, add 0.314g of dimethylaminoethyl methacrylate (DMAEM), 0.07g of glycidyl methacrylate (GMA) and a mixture of 2.5ml of trifluoroethanol and deionized water to it Solvent (V:V=1:1), stirred for 10 minutes and mixed evenly, then added 0.004g initiator AIBN and stirred for 15 minutes, then carried out nitrogen blowing for 15 minutes, then placed in a water bath at 60°C for 6 hours, and waited After the reaction, the reaction flask was opened and placed in an ice-water bath, then the reaction product was poured into an ethanol solution, the precipitated polymer was purified by centrifugation, and finally dried in a vacuum oven to obtain a transparent polymer poly(GMA-co-DMAEMA).

[0036] (2) Weigh 0.06g dopamine hydrochloride and add 30ml Tris-HCl buffer solution, then add 0.18g poly(GMA-co-DMAEMA), 0.12g polylysine and 0.12g poly N-(2-hydroxyethyl) Acrylamide (pHEAA) was finally placed on a glass slide and co-deposited at room temperatur...

Embodiment 3

[0038](1) Take a 50ml round bottom beaker, add N-isopropylacrylamide (NIPAM) monomer 0.23g, glycidyl methacrylate (GMA) 0.07g and 2.5ml of trifluoroethanol and deionized water to it successively Mix the solvent (V:V=1:1), stir for 10 minutes and mix evenly, then add 0.004g initiator AIBN and stir for 15 minutes, then carry out nitrogen blowing for 15 minutes, and then place it in a water bath at 60°C for 6 hours. After the reaction is over, open the reaction flask and place it in an ice-water bath, then pour the reaction product into an ethanol solution, centrifuge and purify the precipitated polymer, and finally dry it in a vacuum oven to obtain a transparent polymer poly(GMA-co-NIPAM) .

[0039] (2) Weigh 0.06g of dopamine hydrochloride and add 30ml of Tris-HCl buffer solution, then add 0.18g of poly(GMA-co-NIPAM), 0.12g of polylysine and 0.12g of poly-N-(2-hydroxyethyl) Acrylamide (pHEAA) was finally placed on a glass slide and co-deposited at room temperature for 48 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com