S/Co/CNF composite material based on waste cigarette ends as well as preparation method and application of S/Co/CNF composite material

A composite material, cigarette butt technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of obvious "shuttle effect", low degree of graphitization, poor cycle stability, etc., to slow down the shuttle effect, no cost, high The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

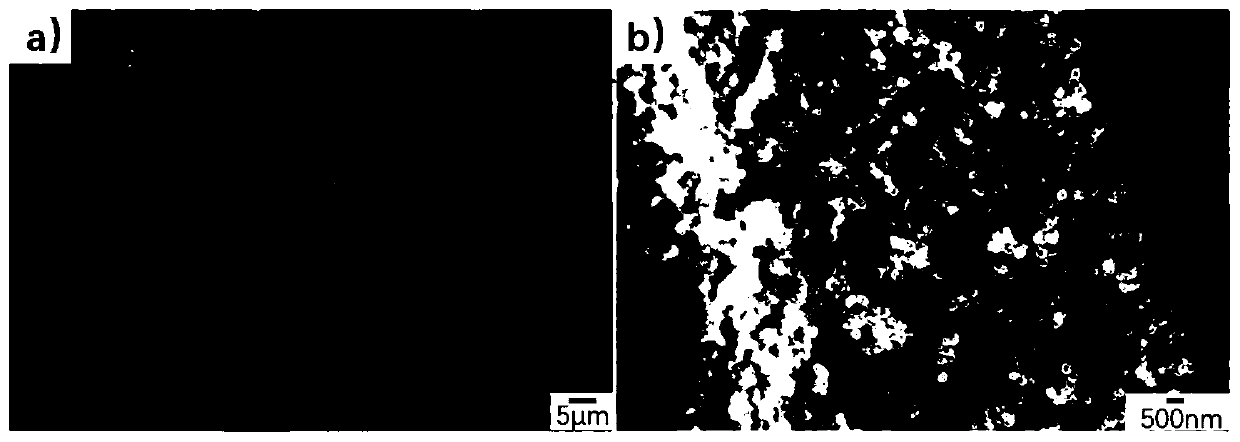

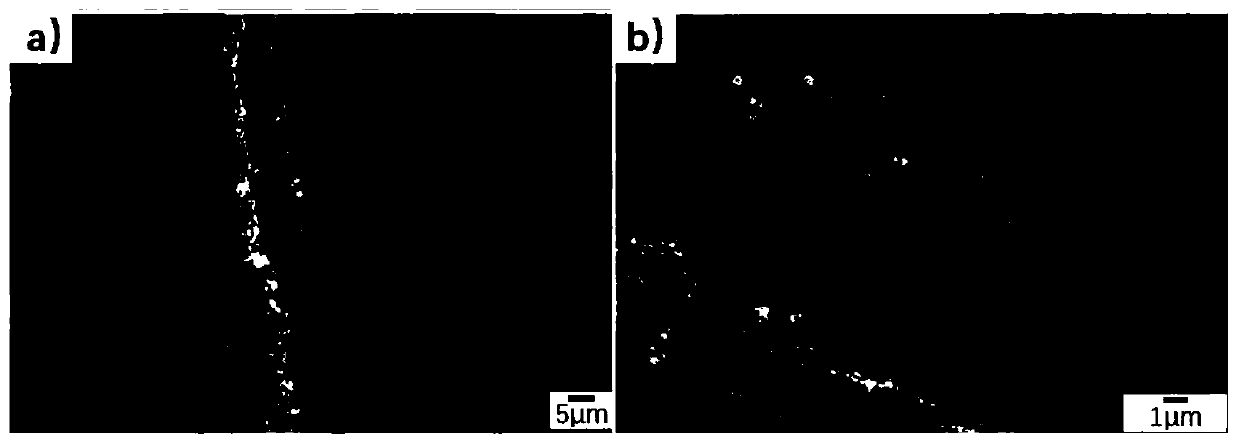

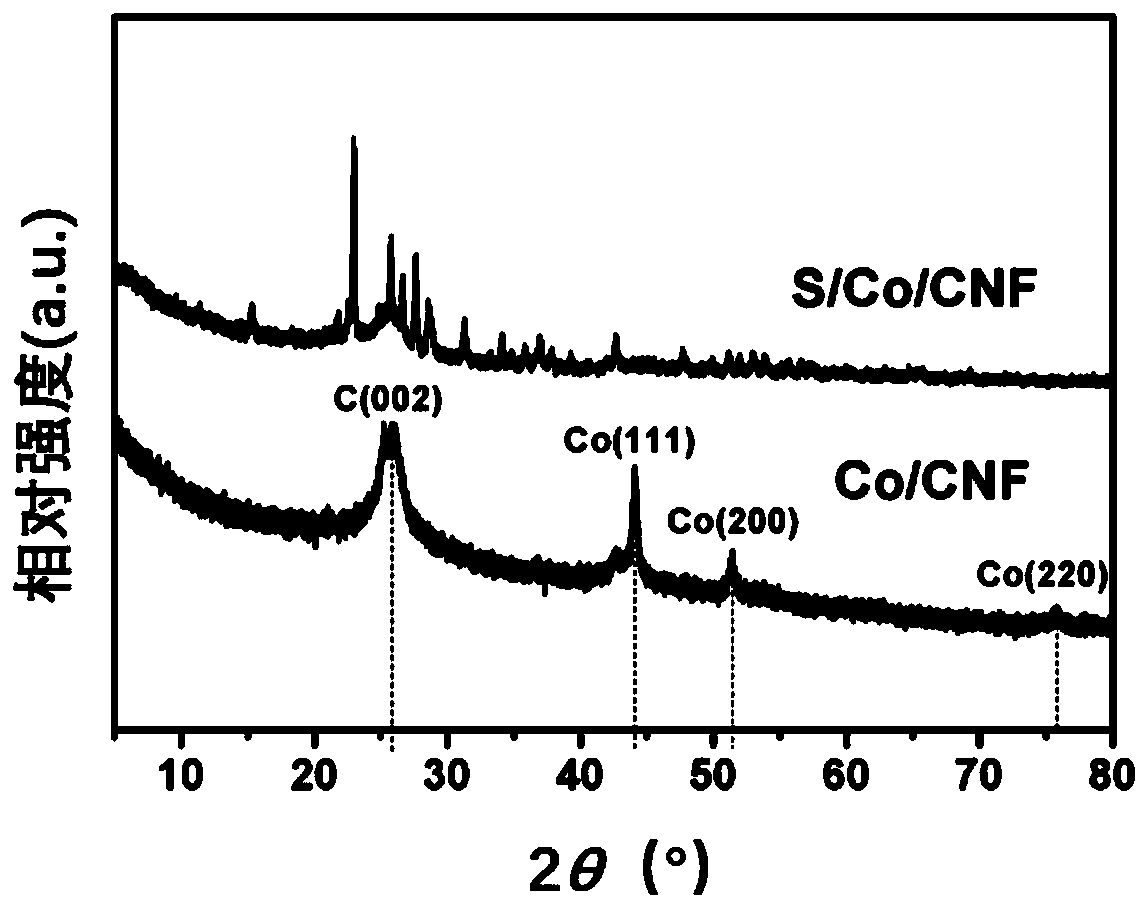

Method used

Image

Examples

Embodiment 1

[0037] 1) Pretreatment of waste cigarette butts

[0038]Put the collected waste cigarette butts into a beaker after removing the wrapping paper, add an appropriate amount of ethanol to soak for 3 hours, and pour off the soaked ethanol to remove the remaining shredded tobacco and ash on the discarded cigarette butts. Then put the soaked waste cigarette butts in a vacuum drying oven at 60°C for 12 hours, and the obtained product is marked as CB;

[0039] 2) Preparation of CB@Co / Zn-ZIF precursor

[0040] Take 0.5 g of the CB obtained in step 1) and place it in a mixture of 2-methylimidazole, Co salt and Zn salt. After standing at room temperature for 12 hours, take out the CB and put it in a vacuum drying oven for 12 hours at 60°C. The CB@Co / Zn-ZIF precursor was obtained. The ratio of the molar weight of 2-methylimidazole in the mixed solution to the total molar weight of Co salt and Zn salt is 4:1; wherein the molar ratio of Co salt and Zn salt is 1:10; the cobalt salt and zin...

Embodiment 2

[0046] 1) Pretreatment of waste cigarette butts

[0047] The collected discarded cigarette butts were put into a beaker after the wrapping paper was removed, and ethanol was added to soak for 3 hours. Then put the soaked waste cigarette butts in a vacuum drying oven at 60°C for 12 hours, and the obtained product is marked as CB;

[0048] 2) Preparation of CB@Co / Zn-ZIF precursor

[0049] Take 1.0 g of the CB obtained in step 1) and place it in a mixture of 2-methylimidazole, Co salt and Zn salt. After standing at room temperature for 12 hours, take out the CB and put it in a vacuum drying oven for 12 hours at 60°C. The CB@Co / Zn-ZIF precursor was obtained. The ratio of the molar weight of 2-methylimidazole in the mixed solution to the total molar weight of Co salt and Zn salt is 4:1; wherein the molar ratio of Co salt and Zn salt is 1:5; the cobalt salt and zinc salt used are respectively Cobalt nitrate hexahydrate and zinc nitrate hexahydrate;

[0050] 3) Preparation of Co / ...

Embodiment 3

[0055] 1) Pretreatment of waste cigarette butts

[0056] The collected discarded cigarette butts were put into a beaker after the wrapping paper was removed, and ethanol was added to soak for 3 hours. Then put the soaked waste cigarette butts in a vacuum drying oven at 60°C for 12 hours, and the obtained product is marked as CB;

[0057] 2) Preparation of CB@Co / Zn-ZIF precursor

[0058] Take 1.0 g of the CB obtained in step 1) and place it in a mixture of 2-methylimidazole, Co salt and Zn salt. After standing at room temperature for 24 hours, take out the CB and put it in a vacuum drying oven at 60°C for 12 hours. The CB@Co / Zn-ZIF precursor was obtained. The ratio of the molar weight of 2-methylimidazole in the mixed solution to the total molar weight of Co salt and Zn salt is 8:1; wherein the molar ratio of Co salt and Zn salt is 1:1; the cobalt salt and zinc salt used are respectively Cobalt nitrate hexahydrate and zinc nitrate hexahydrate;

[0059] 3) Preparation of Co / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com