Composite titanium dioxide photocatalyst

A titanium dioxide and photocatalyst technology is applied in the field of photocatalytic materials to achieve the effects of low cost, mild reaction conditions and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

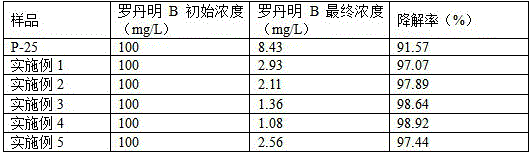

Examples

Embodiment 1

[0025] A kind of composite titanium dioxide photocatalyst, get each raw material according to following ratio: TiO Powder 10kg, polyethylene glycol stearate 0.8kg, manganese slag 1.0kg, iron porphyrin 0.3kg, lanthanum oxide 0.05kg and starch 1kg, Its preparation method comprises the following steps:

[0026] (1) Add Ti02 powder and polyethylene glycol stearate into an ultrasonic generator, then add 20kg of ethanol, and ultrasonicate for 60min at a frequency of 40KHz to obtain a titanium-based suspension;

[0027] (2) Put the titanium-based suspension, manganese slag, iron porphyrin, lanthanum oxide and starch into the ball mill, then add 40kg of water, and stir for 60min at a speed of 300r / min to obtain a paste;

[0028] (3) Microwave dry the above paste at 70°C for 2h, grind it into a powder with a particle size of 1.0mm after drying, and then put it into a horse boiling furnace and bake it at a temperature of 600°C for 6h to obtain a photocatalyst.

Embodiment 2

[0030] A kind of composite titanium dioxide photocatalyst, get each raw material according to following ratio: TiO2 powder body 10kg, macrogol stearate 0.6kg, manganese slag 1.2kg, iron porphyrin 0.2kg, lanthanum oxide 0.1kg and starch 1.2kg , its preparation method comprises the following steps:

[0031] (1) Add Ti02 powder and polyethylene glycol stearate into an ultrasonic generator, then add 30kg of ethanol, and ultrasonicate for 30min at a frequency of 60KHz to obtain a titanium-based suspension;

[0032] (2) Put the titanium-based suspension, manganese slag, iron porphyrin, lanthanum oxide and starch into the ball mill, then add 50kg of water, and stir for 30min at a speed of 500r / min to obtain a paste;

[0033] (3) Microwave dry the above paste at 80°C for 1.5h, grind it into a powder with a particle size of 1.0mm after drying, and then put it into a horse boiling furnace and bake it at 700°C for 5h to obtain a photocatalyst.

Embodiment 3

[0035] A kind of composite titanium dioxide photocatalyst, get each raw material according to following ratio: TiO2 powder body 10kg, macrogol stearate 1.0kg, manganese slag 1.2kg, cobalt porphyrin 0.4kg, lanthanum oxide 0.05kg and starch 1.5kg , its preparation method comprises the following steps:

[0036] (1) Add Ti02 powder and polyethylene glycol stearate into an ultrasonic generator, then add 30kg of ethanol, and ultrasonicate for 45min at a frequency of 50KHz to obtain a titanium-based suspension;

[0037] (2) Put the titanium-based suspension, manganese slag, cobalt porphyrin, lanthanum oxide and starch into the ball mill, then add 40kg of water, and stir for 60min at a speed of 500r / min to obtain a paste;

[0038] (3) Microwave dry the above paste at 90°C for 1.5h, grind it into a powder with a particle size of 1.0mm after drying, and then put it into a horse boiling furnace and bake it at a temperature of 700°C for 4h to obtain a photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com