Biostimulant and preparation method thereof

A technology of biostimulants and trace elements, applied in the field of biological agriculture, can solve the problems of long fermentation process, complicated production process, bringing in a large amount of impurities, etc., to stimulate the potential of crops, improve stress resistance, and improve the effect of survival rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of biostimulant, comprising the following steps:

[0033] (1) Ingredients: In the anaerobic fermentation tank, add 92.8% industrial water, 5.5% beef extract, 0.2% potassium dihydrogen phosphate, and 1.5% EM bacterial agent in sequence, and fully stir;

[0034] (2) Fermentation: The system is subjected to anaerobic fermentation at a temperature of 36° C. After 24 hours, the temperature drops to 30° C. and continues anaerobic fermentation for 7 days;

[0035] (3) Termination of fermentation: use the principle of pasteurization to inactivate the bacteria in the system, after cooling down to room temperature, centrifuge to remove the bacteria, and keep the bacteria liquid as the basic product;

[0036] (4) Product molding: according to the weight of the above bacterial liquid, add 1.2% copper sulfate, 2.5% ferrous sulfate, 1.25% manganese sulfate and 1% zinc oxide in sequence to obtain the target biostimulant.

[0037] As described in step (1), after dro...

Embodiment 2

[0045] A preparation method of biostimulant, comprising the following steps:

[0046] (1) Ingredients: In the anaerobic fermentation tank, add 91.3% industrial water, 6% beef extract, 0.2% potassium dihydrogen phosphate, and 2.5% EM bacterial agent in sequence, and fully stir;

[0047] (2) Fermentation: The system is subjected to anaerobic fermentation at a temperature of 35° C. After 24 hours, the temperature drops to 32° C. and continues anaerobic fermentation for 7 days;

[0048] (3) Termination of fermentation: use the principle of pasteurization to inactivate the bacteria in the system, and after cooling down to room temperature, remove the bacteria by centrifugation;

[0049] (4) Product forming: according to the weight of the above-mentioned bacterial liquid, add 1.4% copper sulfate, 2.7% ferrous sulfate, 1.3% manganese sulfate and 1.2% zinc oxide successively to obtain the target biostimulant.

[0050] As described in step (1), after putting in 6% beef extract, suspen...

experiment example 1

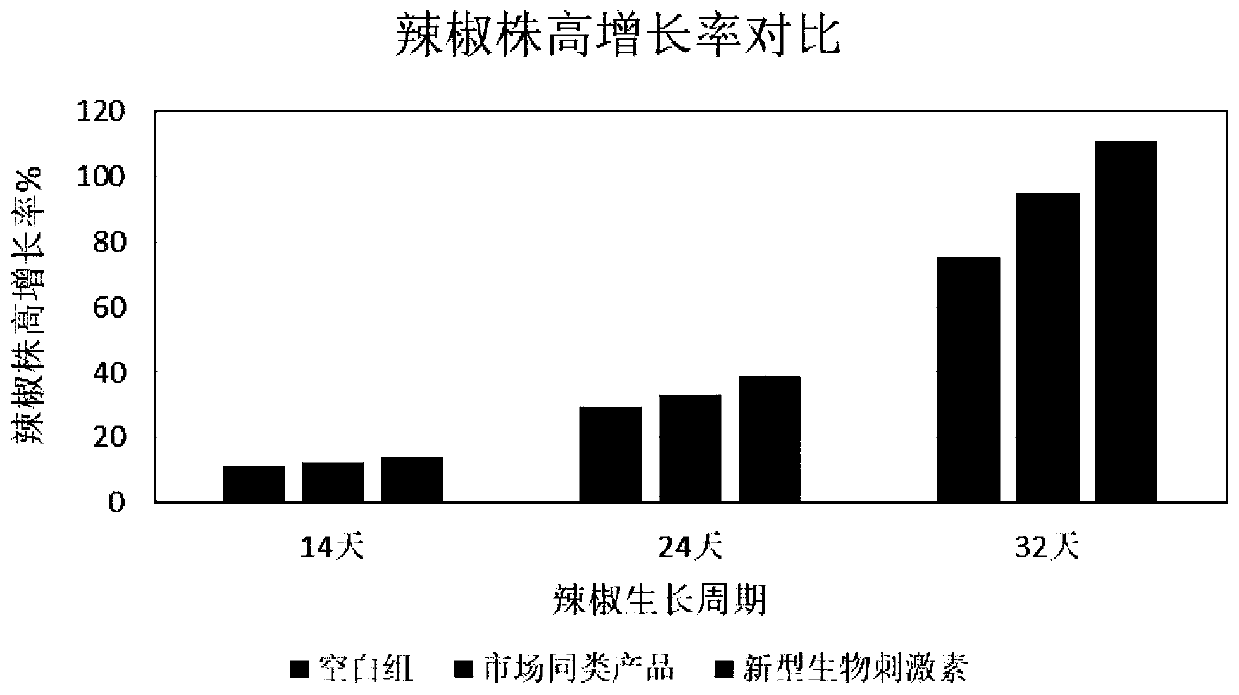

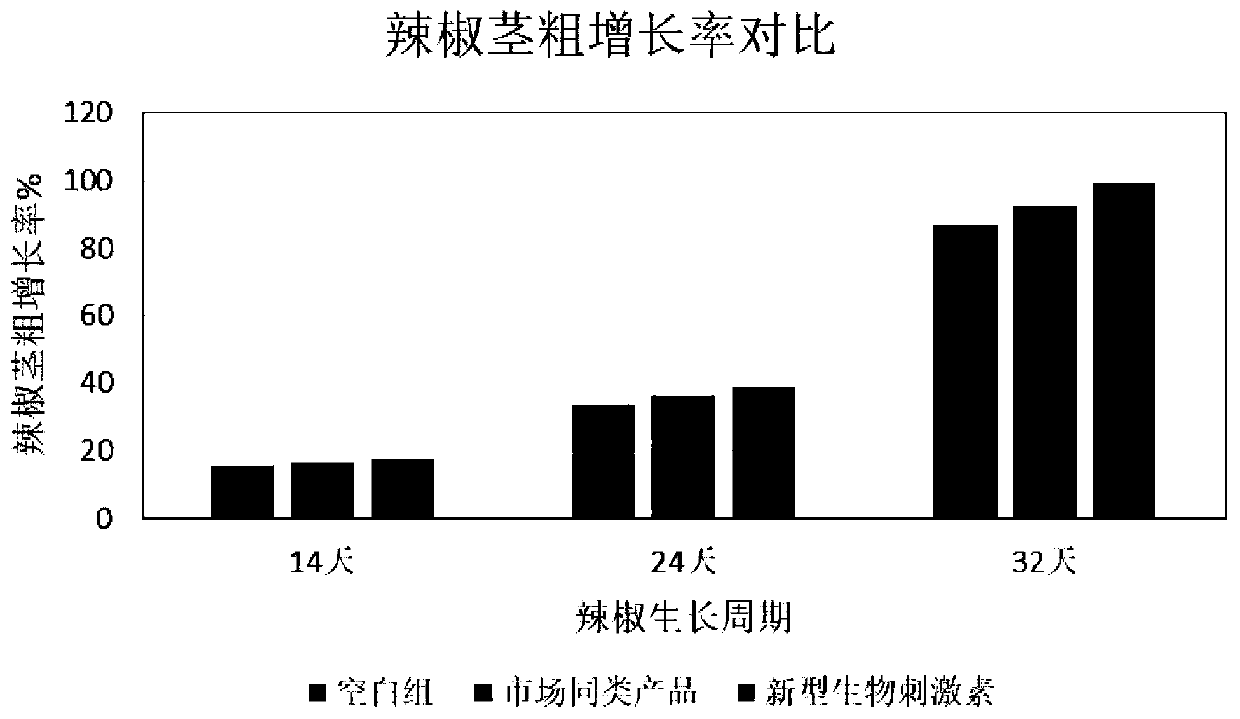

[0059] Select capsicum as experimental object, verify the effect of novel biostimulant in embodiment 1, specifically as follows:

[0060] (1) Test conditions: the test crop is capsicum, and the cultivation method is field planting;

[0061] (2) Drug experiment design: the new biostimulant addition group is the experimental group, and at the same time set up similar products in the market and a blank control;

[0062] (3) Division of test areas: each test area is independent of each other and maintains consistent water and fertilizer, and each handles 30 plants;

[0063] (4) spraying method: before spraying, carry out the measurement of pepper seedling plant height and stem diameter index in each test area and make a good record, then carry out foliar spraying according to the dosage (25g / 15L water) of medicament experiment design, respectively with After 14 days, 24 days, and 32 days after the application of the medicine, measure the plant height and stem diameter of the pepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com