Oil product recovering, granulating and drying device for oily sludge

A technology of granulation and oil products, applied in the field of solid waste disposal and treatment, can solve the problems of immature equipment, easy agglomeration of sludge, blockage of equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

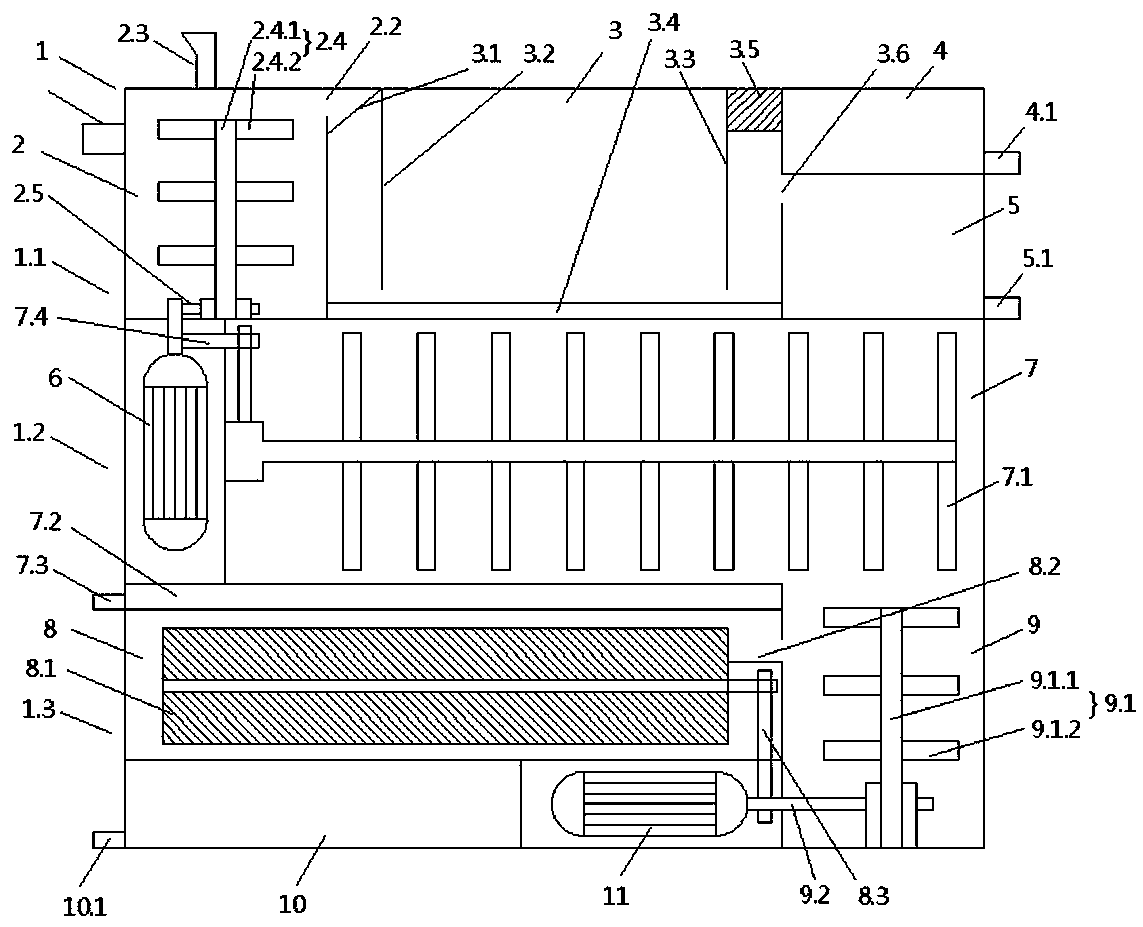

[0030] A device for oil recovery and granulation and drying of oily sludge mainly includes a box body 1; the box body 1 is divided into an upper layer 1.1, a middle layer 1.2 and a lower layer 1.3; the upper layer 1.1 is sequentially provided with demulsification from left to right Zone 2, three-phase separation zone 3 and oil storage zone 4; the middle layer 1.2 is set with a first motor 6 and a filter press zone 7 from left to right; the lower layer 1.3 is set with a granulation zone 8 and stirring from left to right Zone 9; a particle zone 10 and a second motor 11 are also set below the granulation zone 8; and a sewage zone 5 is also set below the oil storage zone 4.

[0031] Preferably, the box body 1 can be made of stainless steel.

[0032] Preferably, the stirring zone 9 can optionally be provided with a feeding port, and when the organic matter content of the oily sludge is high, the microbial inoculum can be added through the feeding port for granulation to make organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com