Method used for preparing diclofenac sodium surface molecular imprinting polymer in water phase taking ZIF-67 as catalyst

A technology of surface molecular imprinting and ZIF-67, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of low cost, good selection and recognition ability, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

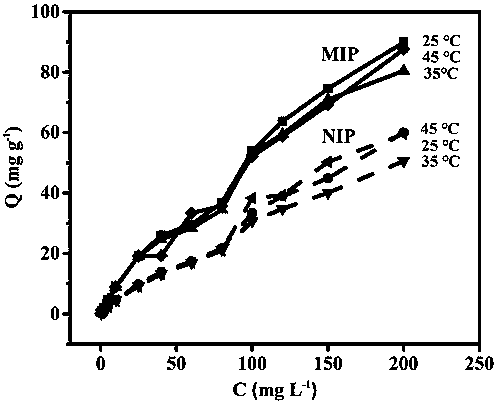

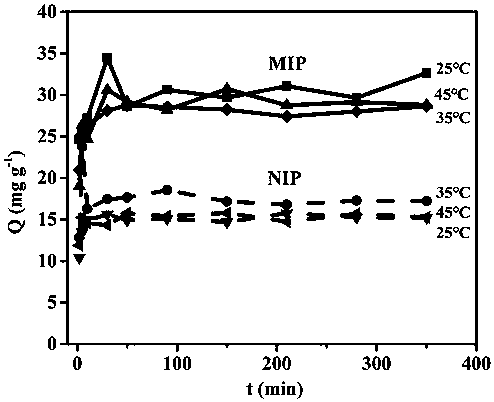

Image

Examples

Embodiment 1

[0020] In a 250 mL conical flask, add 0.1776 g of 1-allyl-3-vinylimidazole tetrafluoroborate, 0.1593 g of diclofenac sodium, 0.2 g of ZIF-67 and 50 mL of pure water, respectively, and shake at 30 °C for pre-treatment. After 4 h of polymerization, 1.8500 g of N,N'-methylenebisacrylamide and 10 mg of azobisisobutyronitrile were added in sequence, and then the polymerization reaction was shaken in a water bath at 60 °C for 24 h. The obtained product was treated with methanol / acetic acid (V :V=9:1) mixed solution Soxhlet extraction for 48 h to remove diclofenac sodium, then rinsed with methanol to neutrality, and then vacuum-dried at 60 ℃ to obtain the target product diclofenac sodium surface molecularly imprinted polymer. The preparation method of the non-molecularly imprinted polymer on the surface of diclofenac sodium is the same as above, except that diclofenac sodium is not added in the process.

Embodiment 2

[0022] In a 250 mL conical flask, add 0.222 g of 1-allyl-3-vinylimidazole tetrafluoroborate, 0.1593 g of diclofenac sodium, 0.3 g of ZIF-67 and 50 mL of pure water, respectively, and shake at 30 °C for pre-treatment. After 4 h of polymerization, 1.5418 g of N,N'-methylenebisacrylamide and 10 mg of azobisisobutyronitrile were added in sequence, and then the polymerization reaction was shaken in a water bath at 60 °C for 24 h. The obtained product was treated with methanol / acetic acid (V :V=9:1) mixed solution Soxhlet extraction for 48 h to remove diclofenac sodium, then rinsed with methanol to neutrality, and then vacuum-dried at 60 ℃ to obtain the target product diclofenac sodium surface molecularly imprinted polymer. The preparation method of the non-molecularly imprinted polymer on the surface of diclofenac sodium is the same as above, except that diclofenac sodium is not added in the process.

Embodiment 3

[0024] In a 250 mL conical flask, add 0.1776 g of 1-allyl-3-vinylimidazole tetrafluoroborate, 0.1593 g of diclofenac sodium, 0.3 g of ZIF-67 and 50 mL of pure water, respectively. After 4 h of polymerization, 1.5418 g of N,N'-methylenebisacrylamide and 10 mg of azobisisobutyronitrile were added in sequence, and then the polymerization reaction was shaken in a water bath at 60 °C for 24 h. The obtained product was treated with methanol / acetic acid (V :V=9:1) mixed solution Soxhlet extraction for 48 h to remove diclofenac sodium, then rinsed with methanol to neutrality, and then vacuum-dried at 60 ℃ to obtain the target product diclofenac sodium surface molecularly imprinted polymer. The preparation method of the non-molecularly imprinted polymer on the surface of diclofenac sodium is the same as above, except that diclofenac sodium is not added in the process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com