Cr-Me multilayer film based on Zr as substrate and preparation method thereof

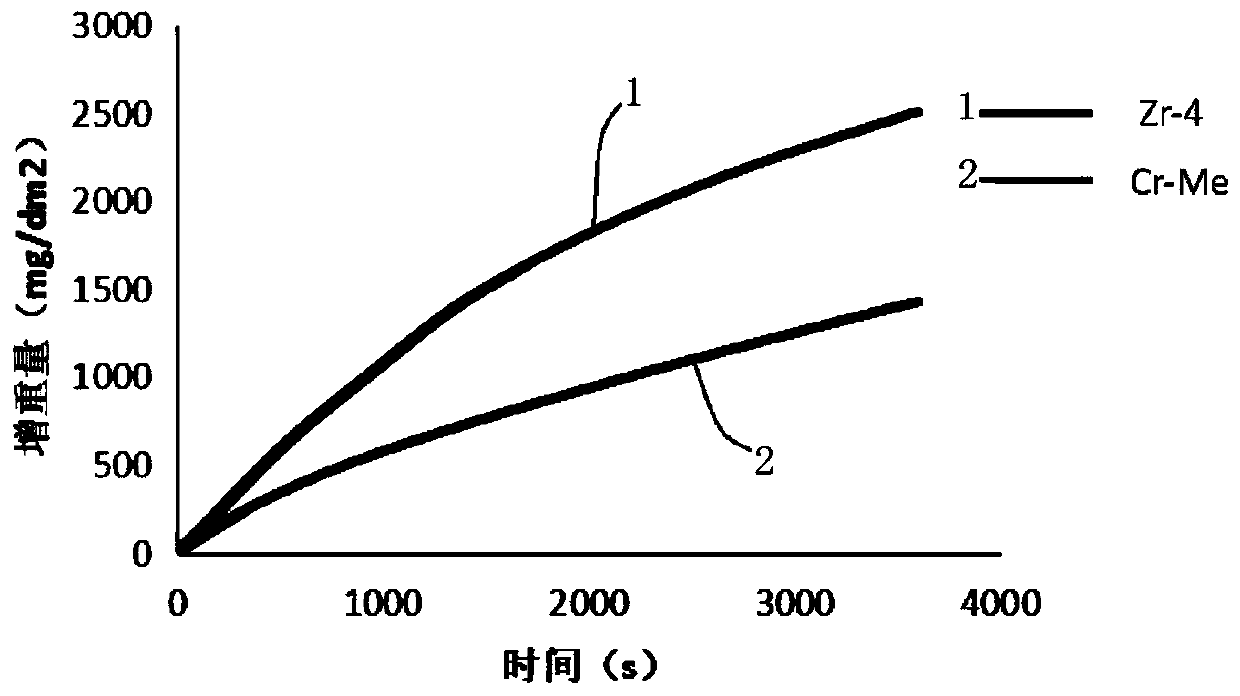

A multi-layer film and substrate technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve problems such as safety accidents, achieve improved corrosion resistance, increase economic benefits and safety, and increase corrosion The effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This implementation case provides a method for preparing a Cr-Al multilayer film, which includes the following steps:

[0027] 1) Cleaning and drying the Zr-4 alloy substrate, and cleaning the equipment.

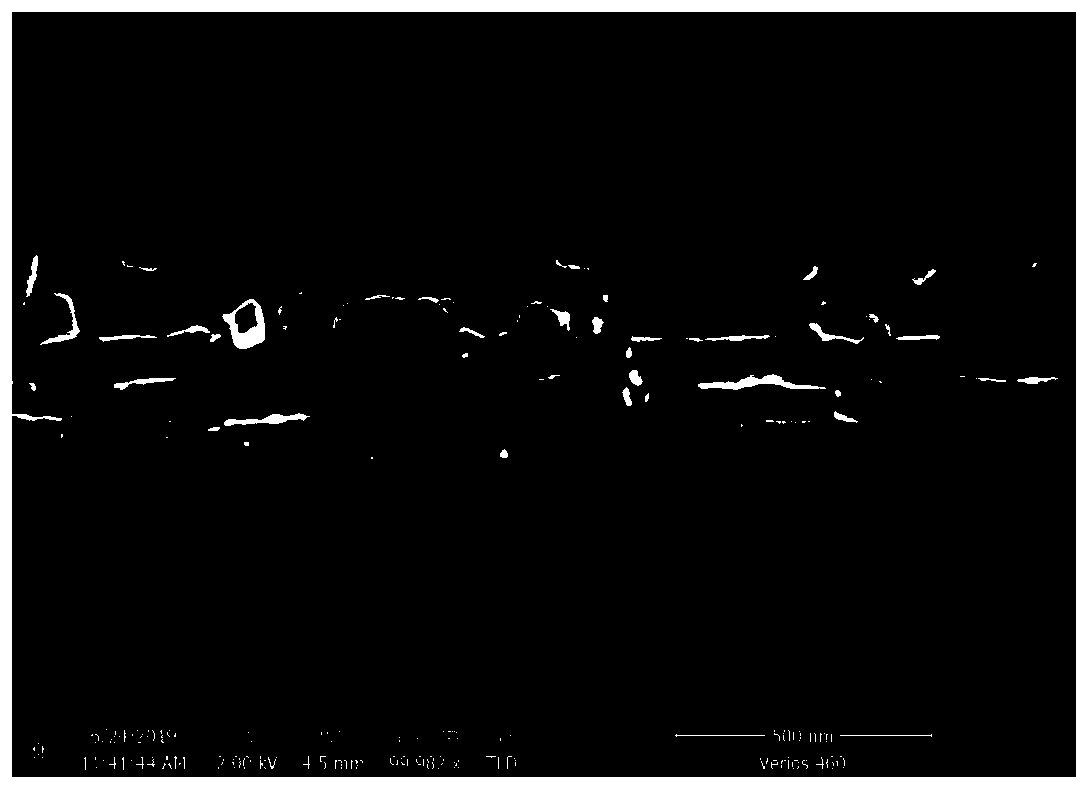

[0028] 2) Sputtering the Cr-Al multilayer film on the surface of the Zr-4 alloy by magnetron sputtering method, and finally obtain the Zr substrate with the Cr-Al multilayer film grown.

[0029] Specifically, in step 1), the substrate is ultrasonically cleaned with absolute ethanol and deionized water for 10 minutes, and then dried with high-purity nitrogen with a purity of 99.99%.

[0030] In step 2), a magnetron sputtering device is used to sputter the Cr-Al multilayer film. Two targets are placed on the rotating substrate holder, where the rotation speed ω=11r / min, the switching time of the target baffle is controlled to control the thickness of the Cr film and the Al film. The target material is a pure Cr target, a pure Al target, and argon with a purity of 99.99%; the s...

Embodiment 2

[0038] This implementation case provides a method for preparing a Cr-Nb multilayer film, which includes the following steps:

[0039] 1) Cleaning and drying the Zr-4 alloy substrate, and cleaning the equipment.

[0040] 2) Sputtering the Cr-Nb multilayer film on the surface of the Zr-4 alloy by magnetron sputtering, and finally obtain the Zr substrate on which the Cr-Nb multilayer film is grown.

[0041] Specifically, in step 1), the substrate is ultrasonically cleaned with absolute ethanol and deionized water for 10 minutes, and then dried with high-purity nitrogen with a purity of 99.99%.

[0042] In step 2), a magnetron sputtering device is used to sputter the Cr-Nb multilayer film. Place two targets on the rotating substrate holder, where the rotation speed ω=11r / min, control the switching time of the target baffle to control the thickness of the Cr film and the Nb film. The target material is a pure Cr target, a pure Nb target, and argon with a purity of 99.99%; the sputtering p...

Embodiment 3

[0049] This implementation case provides a method for preparing a Cr-Zr multilayer film, which includes the following steps:

[0050] 1) Cleaning and drying the Zr-4 alloy substrate, and cleaning the equipment.

[0051] 2) Sputtering the Cr-Zr multilayer film on the surface of the Zr-4 alloy by magnetron sputtering, and finally obtain the Zr substrate on which the Cr-Zr multilayer film is grown.

[0052] Specifically, in step 1), the substrate is ultrasonically cleaned with absolute ethanol and deionized water for 10 minutes, and then dried with high-purity nitrogen with a purity of 99.99%.

[0053] In step 2), a magnetron sputtering device is used to sputter the Cr-Zr multilayer film. Place the Cr and Zr targets on the rotating substrate holder, where the rotation speed ω=11r / min, and pass in argon with a purity of 99.99%; the sputtering power is 120W, the bias voltage is -80V, the argon flow rate is 30sccm, and the working pressure 1.0×10 -4 Pa;; The pre-sputtering time is 15min to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com