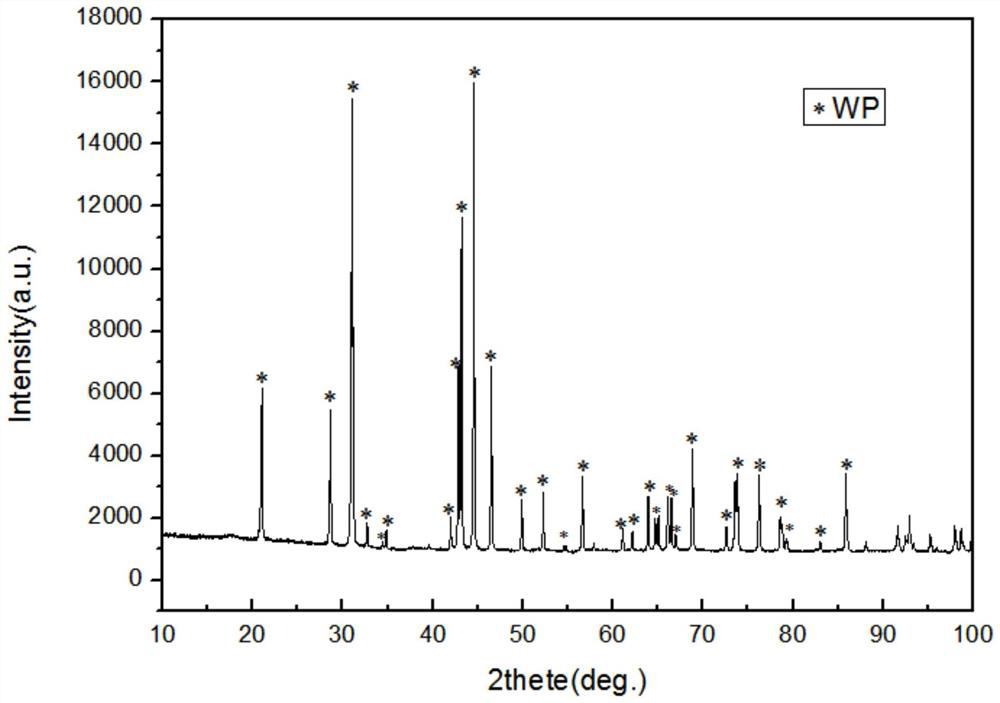

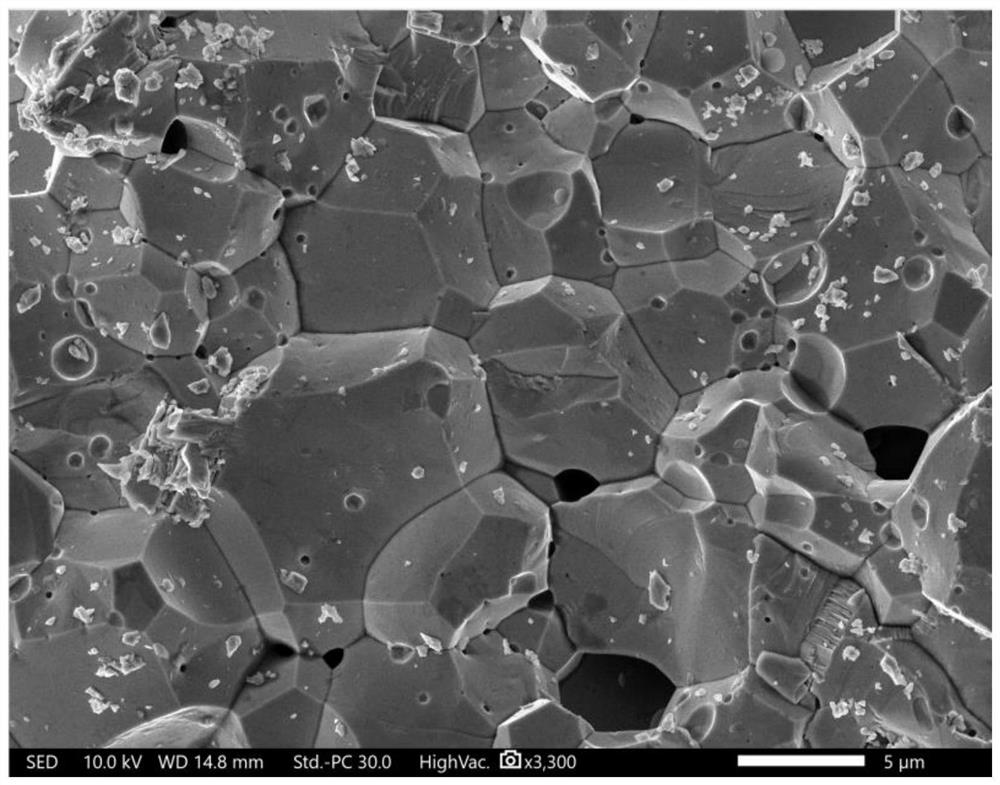

High temperature and high pressure preparation of a conventional superconductor material tungsten phosphide (wp)

A technology of superconductor and tungsten phosphide, which is applied in conventional superconductor material WP, conventional superconductor material WP and its high-temperature and high-pressure preparation field. The effect of high yield and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Take α-phase tungsten powder and red phosphorus powder with a cubic structure with a molar ratio of 1:1 as the initial raw materials, grind the selected raw materials according to the standard of grinding 120 minutes per 1 g of material on average, and pre-press them under a pressure of 10 MPa The cylinder is obtained, and then put into the hBN tube in the pyrophyllite synthesis block. The upper and lower ends of the hBN tube are sealed with hBN sheets to form an hBN column, and then the hBN column is put into the graphite tube, and the upper and lower ends of the graphite tube are assembled with graphite sheets in sequence to form It is the ink column, and then the graphite column is placed in the dolomite tube, and the dolomite sheet, the molybdenum sheet and the conductive steel ring with the graphite column in the middle are assembled at both ends of the dolomite tube. After assembling, put the synthesis block into the synthesis chamber of the large press,...

Embodiment 2

[0024] Example 2: Take α-phase tungsten powder and red phosphorus powder with a cubic structure with a molar ratio of 1:1 as the initial raw materials, grind the selected raw materials according to the standard of 120 min per 1 g of material, and pre-press them under a pressure of 10 MPa The cylinder is obtained, and then put into the hBN tube in the pyrophyllite synthesis block. The upper and lower ends of the hBN tube are sealed with hBN sheets to form an hBN column, and then the hBN column is put into the graphite tube, and the upper and lower ends of the graphite tube are assembled with graphite sheets in sequence to form It is the ink column, and then the graphite column is placed in the dolomite tube, and the dolomite sheet, the molybdenum sheet and the conductive steel ring with the graphite column in the middle are assembled at both ends of the dolomite tube. After assembling, put the synthesis block into the synthesis chamber of the large press, press at a temperature ...

Embodiment 3

[0025] Example 3: Take α-phase tungsten powder and red phosphorus powder with a cubic structure with a molar ratio of 1:1 as the initial raw materials, grind the selected raw materials according to the standard of 120 min per 1 g of material, and pre-press them under a pressure of 10 MPa The cylinder is obtained, and then put into the hBN tube in the pyrophyllite synthesis block. The upper and lower ends of the hBN tube are sealed with hBN sheets to form an hBN column, and then the hBN column is put into the graphite tube, and the upper and lower ends of the graphite tube are assembled with graphite sheets in sequence to form It is the ink column, and then the graphite column is placed in the dolomite tube, and the dolomite sheet, the molybdenum sheet and the conductive steel ring with the graphite column in the middle are assembled at both ends of the dolomite tube. After assembling, put the synthesis block into the synthesis cavity of the large press, press at a temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com