Finishing method of absorbent cotton gauze to achieve sustained-release bacteriostatic performance and high liquid absorption rate

A kind of absorbent cotton, high liquid absorption technology, applied in the direction of fiber treatment, biochemical fiber treatment, improved hand-feeling fiber, etc., can solve problems such as damage, the output of Sophora flavescens root cannot meet clinical needs, etc., and achieve improved liquid absorption performance, excellent sustained release Antibacterial properties, good antibacterial activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

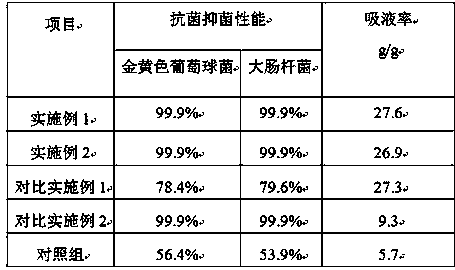

Examples

Embodiment 1

[0034] A slow-release antibacterial-high liquid absorption finishing method for absorbent cotton gauze, characterized in that it comprises the following steps, the following raw materials are by weight:

[0035] (1) Oxidation treatment method of absorbent cotton gauze:

[0036] Heat 100 parts of sodium percarbonate solution in a water bath to 40°C, put 10 parts of absorbent cotton gauze into it, adjust the pH to 9, oxidize for 2 hours, take it out, neutralize it with hydrochloric acid solution to neutrality, fully wash and dry to obtain oxidized Treated absorbent cotton gauze;

[0037] Wherein, the concentration of sodium percarbonate solution is 0.1g / L, and the concentration of hydrochloric acid solution is 6%;

[0038] (2) Slow-release antibacterial treatment of absorbent cotton gauze:

[0039] Dissolve 6 parts of chitosan in acetic acid solution at a ratio of 1:30, stir and mix evenly with a magnetic force, filter and sterilize, soak the oxidized absorbent cotton gauze ob...

Embodiment 2

[0049] A slow-release antibacterial-high liquid absorption finishing method for absorbent cotton gauze, characterized in that it comprises the following steps, the following raw materials are by weight:

[0050] (1) Oxidation treatment method of absorbent cotton gauze:

[0051] Heat 200 parts of sodium percarbonate solution in a water bath to 45°C, put 20 parts of absorbent cotton gauze into it, adjust the pH to 9, oxidize for 1 hour, take it out, neutralize it with hydrochloric acid solution to neutrality, fully wash and dry to obtain oxidized Treated absorbent cotton gauze;

[0052] Wherein, the concentration of sodium percarbonate solution is 0.2g / L, and the concentration of hydrochloric acid solution is 9%;

[0053] (2) Slow-release antibacterial treatment of absorbent cotton gauze:

[0054] Dissolve 12 parts of chitosan in acetic acid solution at a ratio of 1:30, stir and mix evenly, filter and sterilize, soak the oxidized absorbent cotton gauze obtained in (1) for 4 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com