Method for solid ablation direct analysis based on plasma jet and implementation apparatus thereof

A plasma and solid technology, applied in the field of analysis, can solve the problems such as the influence of the accuracy and stability of the test method, the lack of simultaneous multi-element analysis ability, and the inability to realize the on-site detection of samples, so as to avoid the use of dangerous chemical reagents and shorten the detection time. Time, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

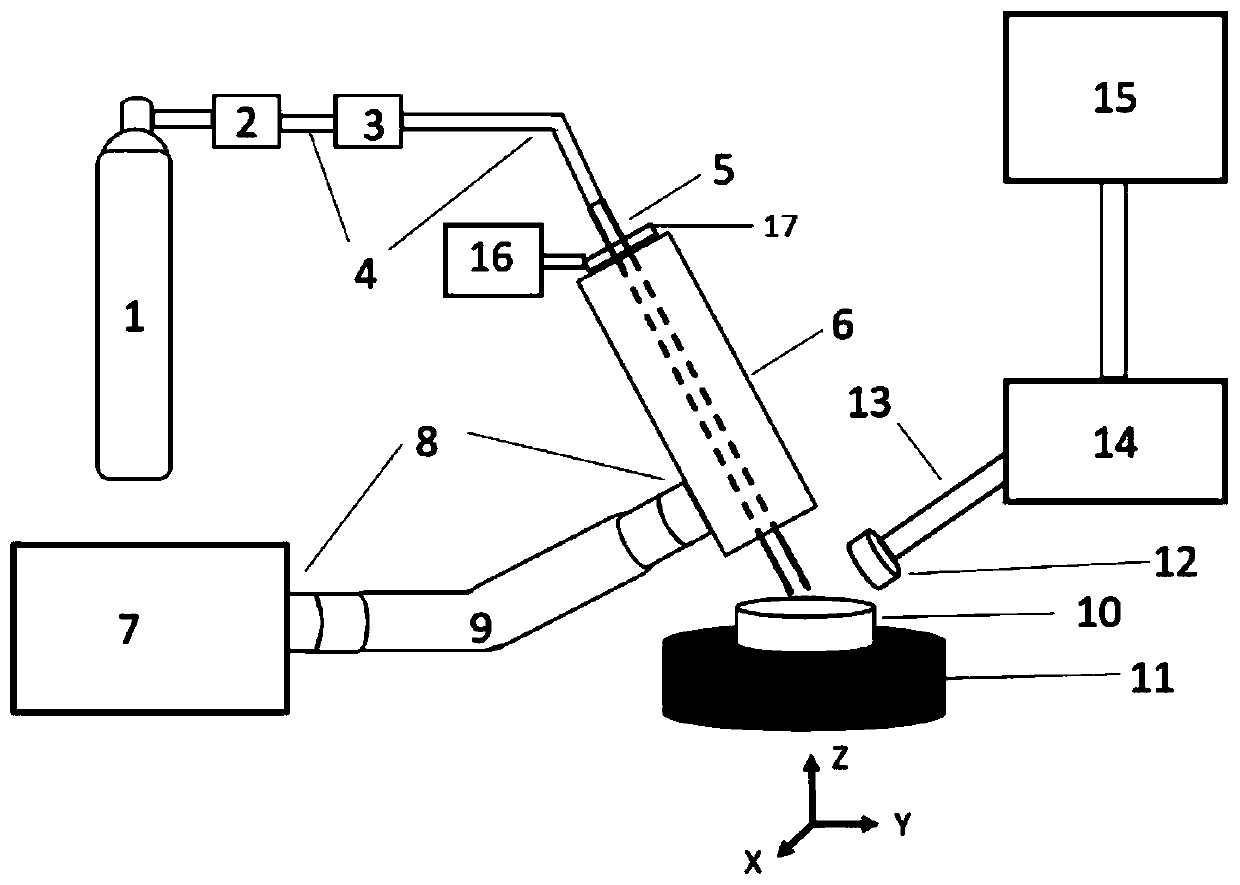

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

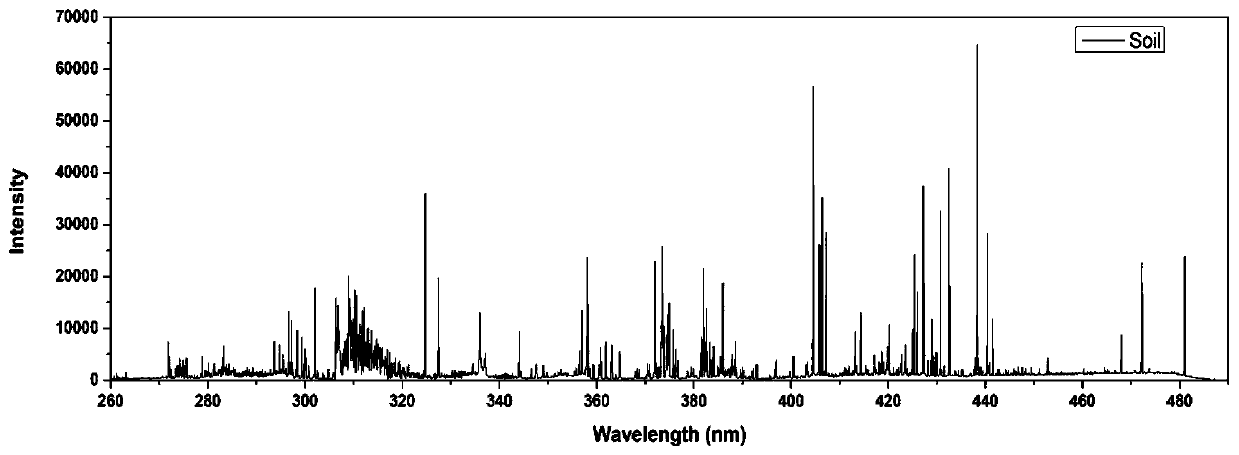

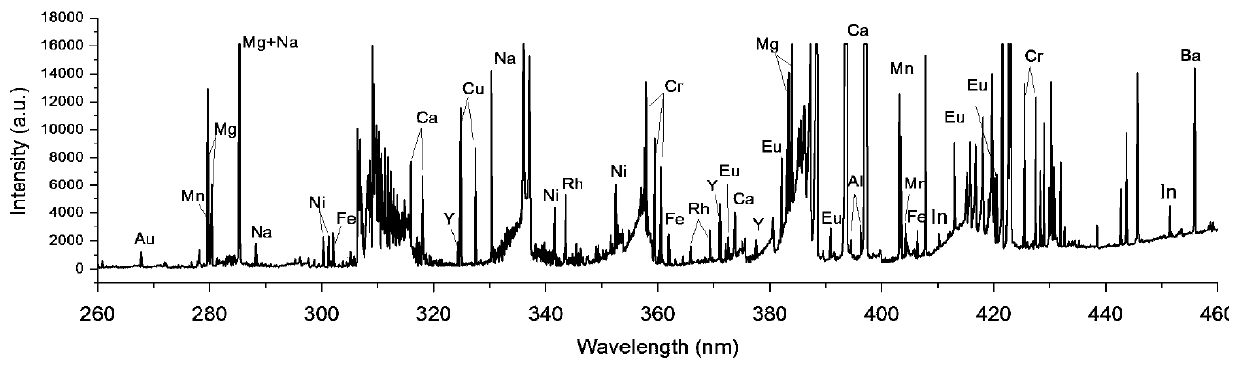

[0033] The method of direct analysis of solid ablation based on plasma jet and its implementation device disclosed in the present invention, the discharge gas enters the discharge tube to absorb microwave energy to generate microwave plasma jet, and under the precise control of the high-precision translation stage, the plasma with high energy density The tail flame ablates the solid, realizes the atomization and excitation of the elements in the solid sample, and realizes the qualitative and quantitative detection of the elements in the sample by collecting the atomic emission spectrum signal. Its analysis program mainly includes:

[0034] (1) The obtained solid sample is subjected to a simple grinding process, and the powder sample is subjected to tableting treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com