A kind of corn seed coating agent and corn seed treatment method

A seed and corn technology, applied in the field of seed coating agent, can solve the problems of low corn yield, weak guarantee of corn seed germination rate and seedling survival rate, single function of coating agent, etc., so as to enhance drought resistance and stress resistance. effect, the effect of enhancing the growth of corn seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

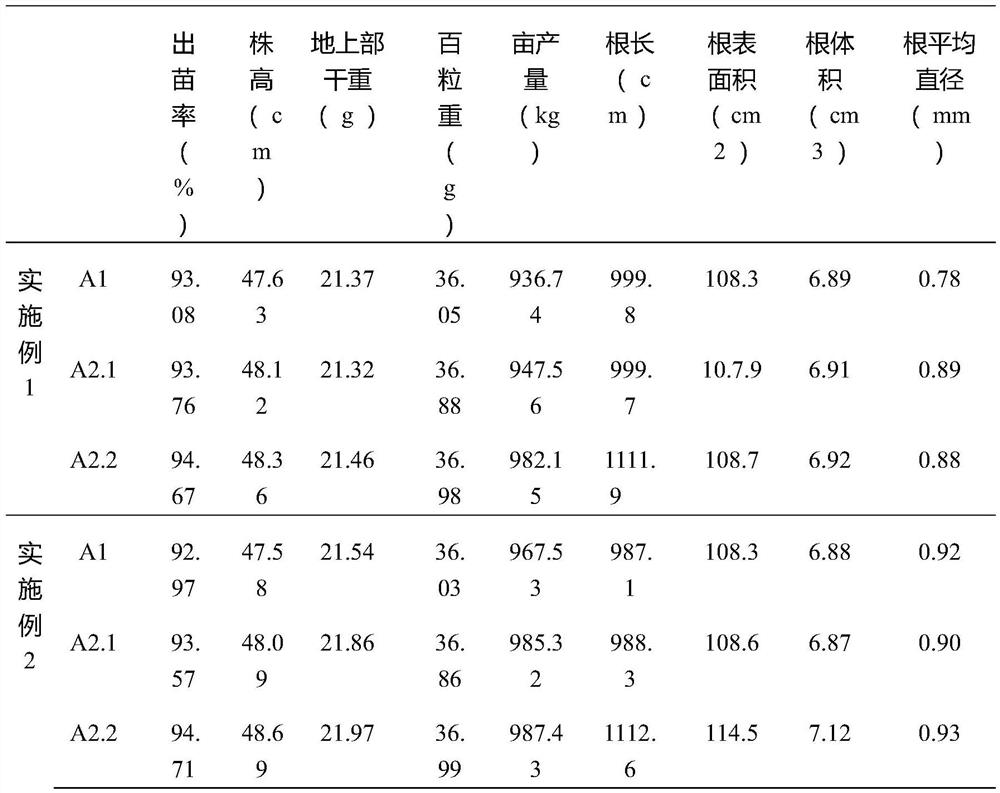

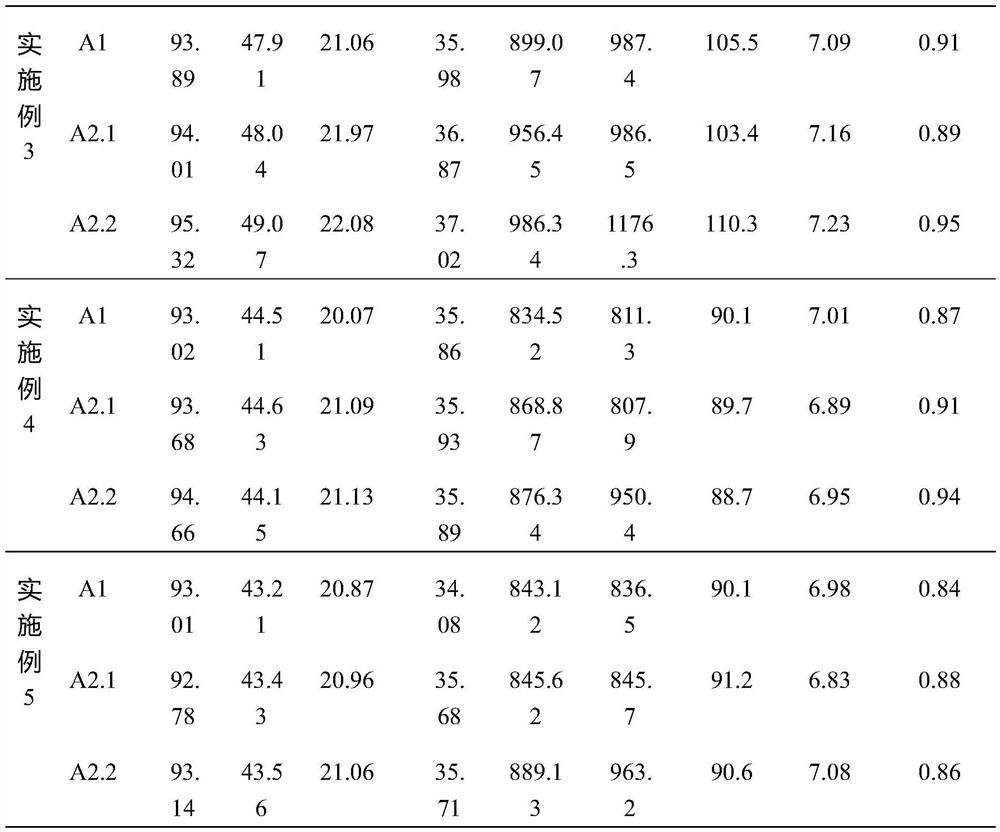

Embodiment 1

[0032] Used for corn seed coating agent, it is composed of dimethyl sulfoxide, polyaspartic acid, sodium carboxymethyl starch, passion fruit husk powder and water, wherein the mass percentage of polyaspartic acid is 40%, dimethyl The mass percentage of base sulfoxide is 4%, the mass percentage of sodium carboxymethyl starch is 20%, the mass percentage of passion fruit husk powder is 5%, and the balance is water; passion fruit husk powder is a powder with a fineness of 50-150 mesh .

[0033] A1: Preparation method: directly mix and mix uniformly into a viscous mixture, directly coat the viscous mixture on the outer surface of the seeds, and the mass ratio of the viscous mixture to the seeds is 1:0.3.

[0034] A2: Preparation method, including the following steps:

[0035] (1) polyaspartic acid is mixed with dimethyl sulfoxide, sodium carboxymethyl starch and water to prepare a viscous mixture;

[0036] (2) after the passion fruit husk is repeatedly pulverized by a pulverizer ...

Embodiment 2

[0041] Used for corn seed coating agent, it is composed of dimethyl sulfoxide, polyaspartic acid, sodium carboxymethyl starch, passion fruit husk powder and water, wherein the mass percentage of polyaspartic acid is 20%, dimethyl The mass percentage of base sulfoxide is 1%, the mass percentage of sodium carboxymethyl starch is 15%, the mass percentage of passion fruit husk powder is 2%, and the balance is water; passion fruit husk powder is a powder with a fineness of 50-150 mesh .

[0042] A1: Preparation method: directly mix and mix uniformly into a viscous mixture, directly coat the viscous mixture on the outer surface of the seeds, and the mass ratio of the viscous mixture to the seeds is 1:0.8.

[0043] A2: Preparation method, including the following steps:

[0044](1) polyaspartic acid is mixed with dimethyl sulfoxide, sodium carboxymethyl starch and water to prepare a viscous mixture;

[0045] (2) after the passion fruit husk is repeatedly pulverized by a pulverizer f...

Embodiment 3

[0050] Used for corn seed coating agent, it is composed of dimethyl sulfoxide, polyaspartic acid, sodium carboxymethyl starch, passion fruit husk powder and water, wherein the mass percentage of polyaspartic acid is 30%, dimethyl The mass percentage of base sulfoxide is 3%, the mass percentage of sodium carboxymethyl starch is 18%, the mass percentage of passion fruit husk powder is 3%, and the balance is water; passion fruit husk powder is a powder with a fineness of 50-150 mesh .

[0051] A1: Preparation method: directly mix and mix uniformly to form a viscous mixture, directly coat the viscous mixture on the outer surface of the seeds, and the mass ratio of the viscous mixture to the seeds is 1:0.5.

[0052] A2: Preparation method, including the following steps:

[0053] (1) polyaspartic acid is mixed with dimethyl sulfoxide, sodium carboxymethyl starch and water to prepare a viscous mixture;

[0054] (2) after the passion fruit husk is repeatedly pulverized by a pulveriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com