Preparation process of novel ester type anti-wear agent for diesel oil

A preparation process and anti-wear agent technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of excessive diesel acidity, affecting the performance of diesel engines, etc., and achieve good anti-emulsification and anti-wear properties. Good, avoid the effect of emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

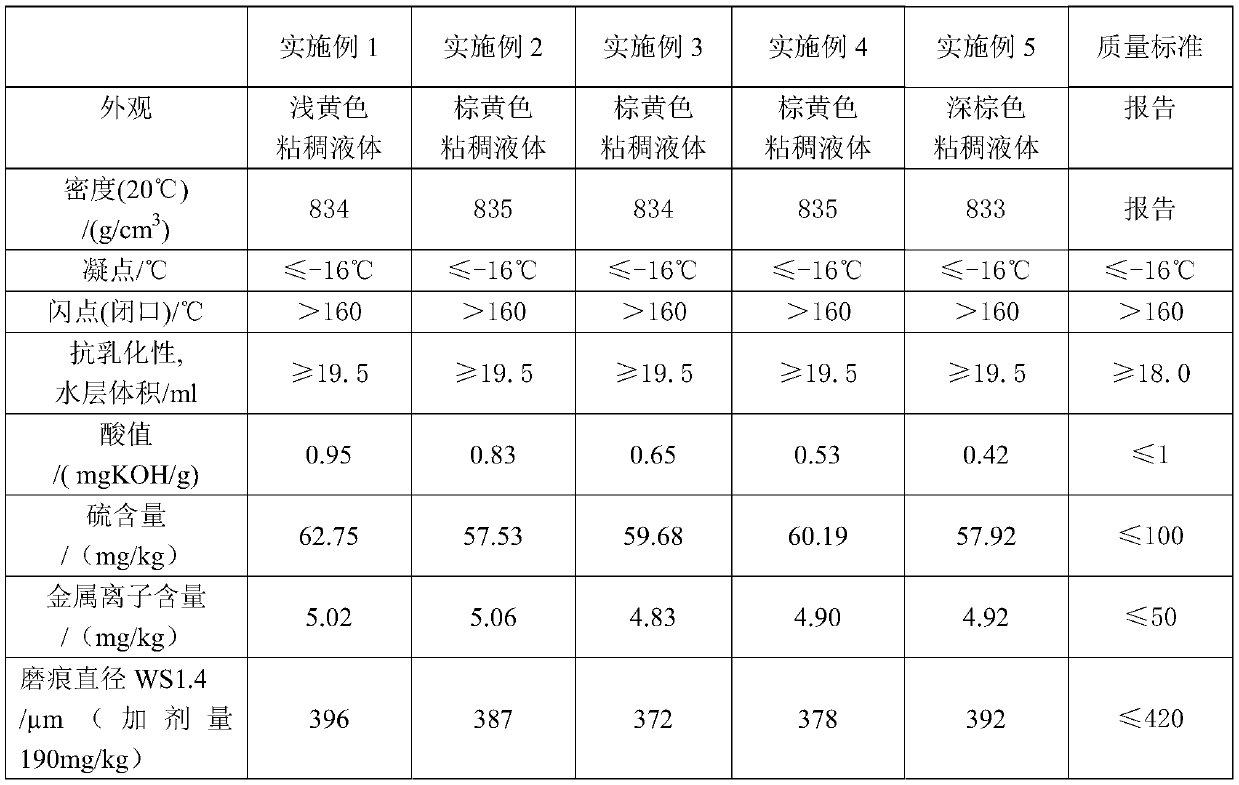

Examples

Embodiment 1

[0025] 1) Add the molecular sieve-supported solid superacid catalyst to ethylene glycol, then add the catalyst-added ethylene glycol to the reaction kettle, and add the water-carrying agent xylene, start stirring, and put the above mixture under a nitrogen atmosphere. Heated to 125°C, then added linoleic acid to carry out esterification reaction at 125°C for 8.0h. Wherein the ratio of ethylene glycol to linoleic acid is 0.9, the molecular sieve-supported solid superacid catalyst addition is 15% of the total mass of reactants, and the water-carrying agent xylene is 130% of the total mass of reactants.

[0026] 2) After the reaction is completed, the temperature is naturally lowered. When the temperature drops to 60° C., the xylene is extracted and removed under reduced pressure, and then the product is filtered to remove the molecular sieve-supported solid catalyst.

[0027] 3) After the product is lowered to room temperature, the remaining trace moisture and inorganic impuriti...

Embodiment 2

[0030] 1) Add the molecular sieve-supported solid superacid catalyst to 1,3-propanediol, then add the catalyst-added 1,3-propanediol to the reaction kettle, and add the water-carrying agent xylene, start stirring under nitrogen protection atmosphere , the above mixture was heated to 128°C, and then linoleic acid was added to carry out esterification reaction at 128°C for 8.5h. Wherein the ratio of 1,3-propanediol to linoleic acid is 0.95, the amount of molecular sieve supported solid superacid catalyst is 20% of the total mass of reactants, and the water-carrying agent xylene is 140% of the total mass of reactants.

[0031] 2) After the reaction is completed, the temperature is naturally lowered. When the temperature drops to 60° C., the xylene is extracted and removed under reduced pressure, and then the product is filtered to remove the molecular sieve-supported solid catalyst.

[0032] 3) After the product is lowered to room temperature, the remaining trace moisture and ino...

Embodiment 3

[0035] 1) Add the molecular sieve-supported solid superacid catalyst to the glycerol, then add the catalyst-added glycerol to the reaction kettle, and add the water-carrying agent xylene, start stirring, and put the above mixture under a nitrogen atmosphere. Heated to 132°C, then added linoleic acid to carry out esterification reaction at 132°C for 9.0h. Wherein the ratio of glycerol to linoleic acid is 1.0, the molecular sieve-supported solid superacid catalyst addition is 28% of the total mass of reactants, and the water-carrying agent xylene is 150% of the total mass of reactants.

[0036] 2) After the reaction is completed, the temperature is naturally lowered. When the temperature drops to 60° C., the xylene is extracted and removed under reduced pressure, and then the product is filtered to remove the molecular sieve-supported solid catalyst.

[0037] 3) After the product is lowered to room temperature, the remaining trace moisture and inorganic impurities in the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com