Serratia sp. and application thereof in protease production

A Serratia and protease technology, applied in the fields of microorganisms and fermentation technology, can solve the problems of complicated preparation steps, high energy consumption, unfavorable industrialization process, etc., and achieves the effects of good pH stability and good temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

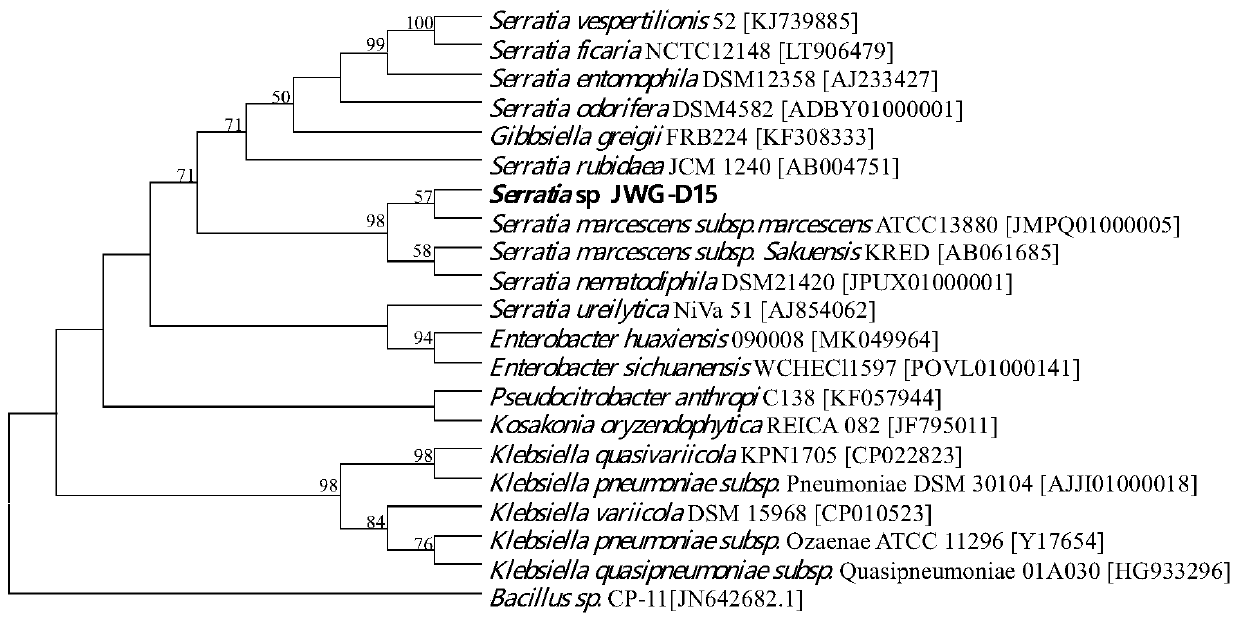

[0061] Embodiment 1: Screening and identification of Serratia sp.

[0062] Specific steps are as follows:

[0063] 1. Screening

[0064] Taking soil from five rice processing factories in Wuxi City, Jiangsu Province as samples, two samples of soil were taken from each rice processing factory, a total of 10 samples; 10 samples were placed in a 60°C oven for 30 minutes after heat treatment, Weigh 1g and add it to 100mL broth-peptone liquid medium, culture at 30°C and 200rpm for 24h for enrichment culture, let it stand for 20min, and take 0.1mL supernatant for gradient dilution (10 -4 , 10 -5 , 10 -6 ) on a screening medium plate containing rice protein, cultivated at 30°C for 2 days, picked colonies with transparent circles around them, separated and purified them by streaking on solid broth peptone medium, and carried out preliminary screening for 3 times to obtain purified Single colony; after inoculating the purified single colony into the slant medium and storing it for ...

Embodiment 2

[0067] Embodiment 2: the cultivation of Serratia sp.

[0068] Specific steps are as follows:

[0069] Scrape a ring of Serratia sp. JWG-D15 obtained in Example 1 from the slant and culture it in LB medium. After cultivating at 30°C for 48 hours, observe its colony and find that its colony is round and convex up, light red, opaque, smooth surface, wet and shiny, neat edges (see details figure 2 ).

[0070] A ring of Serratia sp. JWG-D15 obtained in Example 1 was scraped from the slope and inserted into LB medium with a pH of 3 to 10, and cultured at a constant temperature of 30° C. for 48 hours, and the growth pH was found to be 6.0 ~9.0, the optimum pH is 8.0.

[0071] A ring of Serratia sp. JWG-D15 obtained in Example 1 was scraped from the slope and inserted into the LB medium with a pH of 8, and cultured at a constant temperature of 4 to 50° C. for 48 hours, and the growth temperature was found to be 25℃~40℃, the optimum temperature is 30~37℃.

Embodiment 3

[0072] Example 3: Shake flask fermentation of Serratia sp.

[0073] Specific steps are as follows:

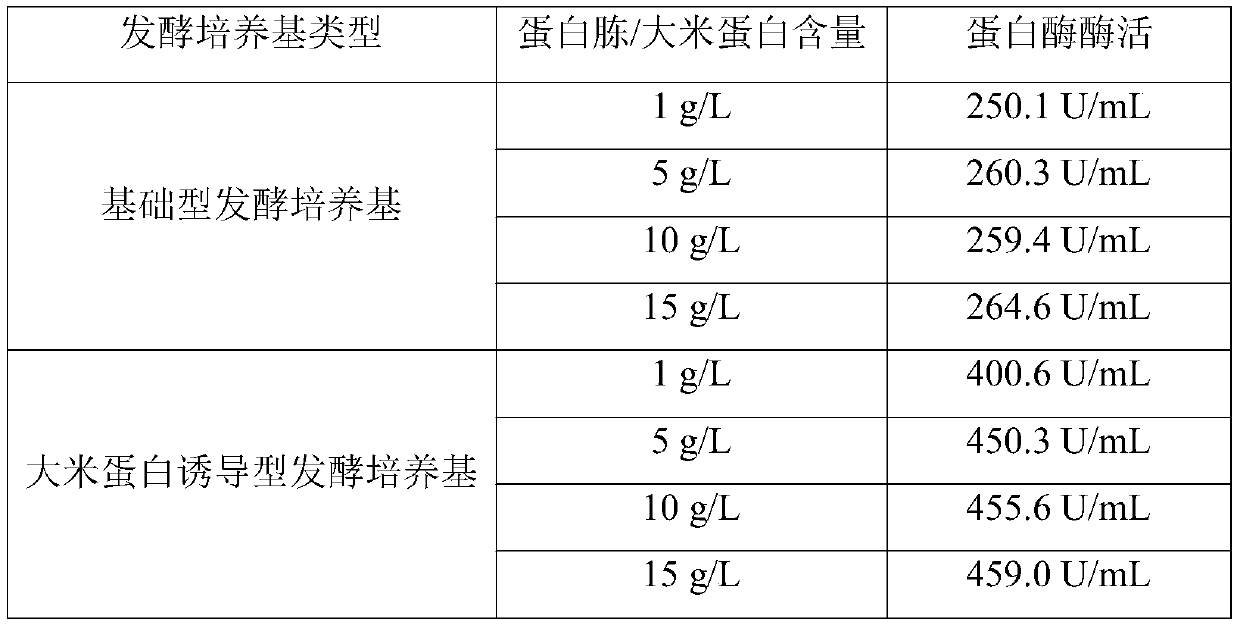

[0074] 1. Basic fermentation

[0075] Scrape a ring of Serratia sp. JWG-D15 obtained in Example 1 from the slope, place it in a 250mL Erlenmeyer flask with 50mL of seed medium, and culture it with shaking at 30°C and 200rpm for 24h , to obtain the seed solution; the seed solution was inserted into a 250mL Erlenmeyer flask equipped with 50mL basic type fermentation medium with an inoculum size of 2.5% (v / v) for fermentation and cultivation, and was shaken for 2 days at 30°C and 200rpm. Obtain a fermentation broth; centrifuge the fermentation broth at 12000 rpm for 10 min to obtain a supernatant.

[0076] 2. Rice protein-induced fermentation

[0077] Scrape a ring of Serratia sp. JWG-D15 obtained in Example 1 from the slope, place it in a 250mL Erlenmeyer flask with 50mL of seed medium, and culture it with shaking at 30°C and 200rpm for 24h , to obtain the seed liquid; the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com