A shallow ultra-soft foundation solidification method combined with vacuum drainage and magnesium oxide carbonization

A solidification method and magnesium oxide technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of long treatment period, poor environmental benefits, and low bearing strength of high moisture content silt soft soil, and achieve shortening solidification. Knot time, high utilization rate, enhanced strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

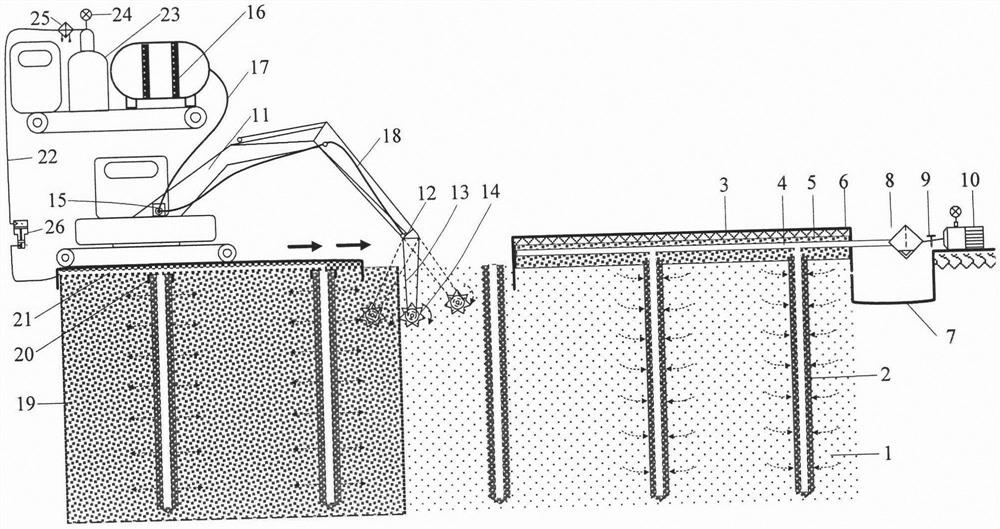

[0060] a. Initial exploration and pretreatment

[0061] Measure the basic physical and chemical indicators of ultra-soft foundation 1 soil, of which the site area is 2500m 2, The average mud depth is 2.5m (the depth of the core area with a site diameter of 20m is 3m, and the depth of the rest is 2m), moisture content is 130%, specific gravity is 2.63, liquid limit is 60%, plastic limit is 30%, organic matter content is 7.0%, pH value is 7.2, solidification The length of the excavator arm 11 of the agent homogenizing equipment 14 is 7m, the length of the mixing arm 13 is 4.5m, combined with physical and chemical indicators, the ultra-soft foundation 1 site is divided into ring-shaped areas according to the length of the excavator arm 11 and the mixing arm 13, and the ring-shaped area is set. The radius is 5m, and the drainage ditch 7 is excavated on the outermost side of the ultra-soft foundation 1, and the periphery of the site is cleaned and leveled.

[0062] b. Arrangement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com