Processing technology of npr steel bars

A processing technology and steel bar technology, applied in the field of NPR steel bar processing technology, can solve the problems of time-consuming and labor-intensive, high labor intensity, inability to use high-carbon steel bars or large-diameter high-carbon steel bars, etc., to avoid surface scratches Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

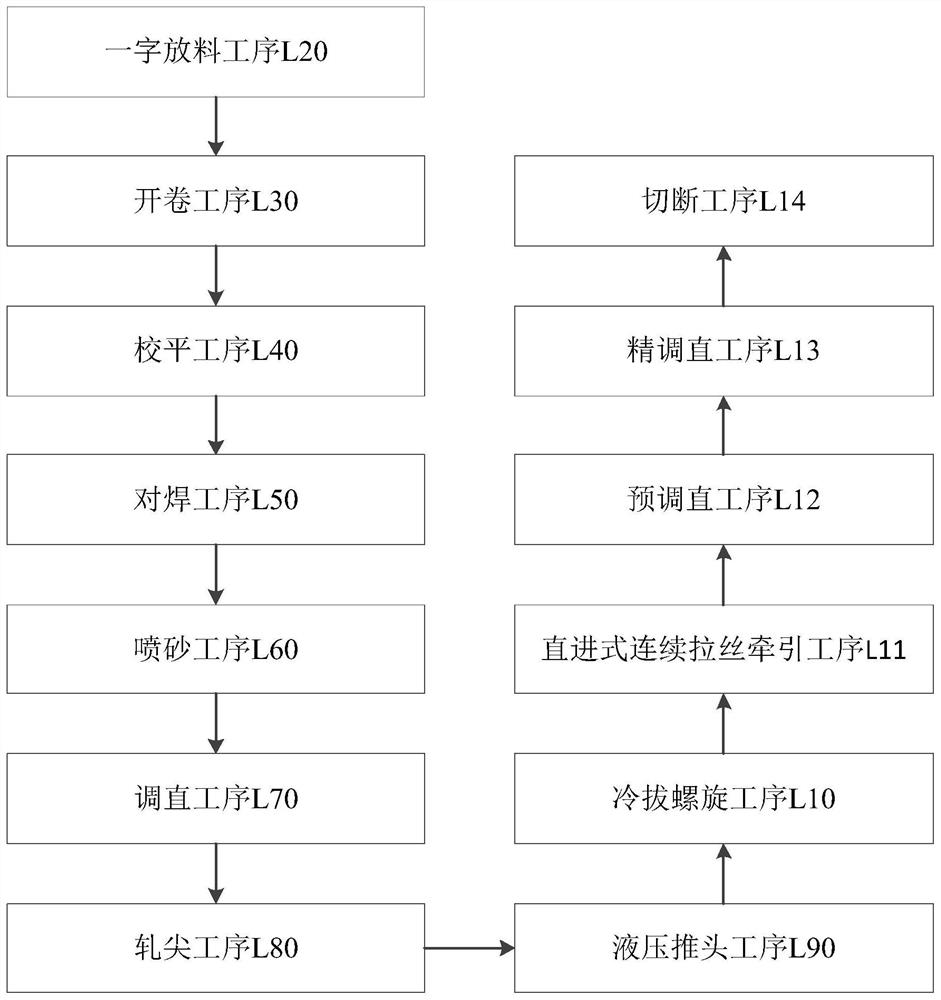

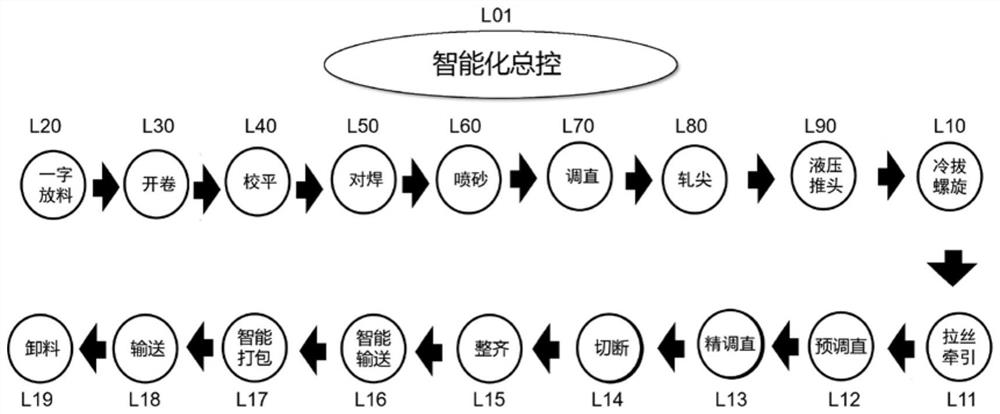

[0042] see figure 1 As shown, according to the embodiments of the present invention, a kind of processing technology of NPR steel bars is provided, which is processed by a fully automatic intelligent NPR cold-rolled (cold-drawn) steel bar production line, and the NPR steel bars are in a cold-worked state, so The yield strength of the NPR steel bar is 800MPa-950MPa, the tensile strength is 900MPa-1100MPa, and the maximum force elongation is ≥10-40%; the steps of the processing technology include:

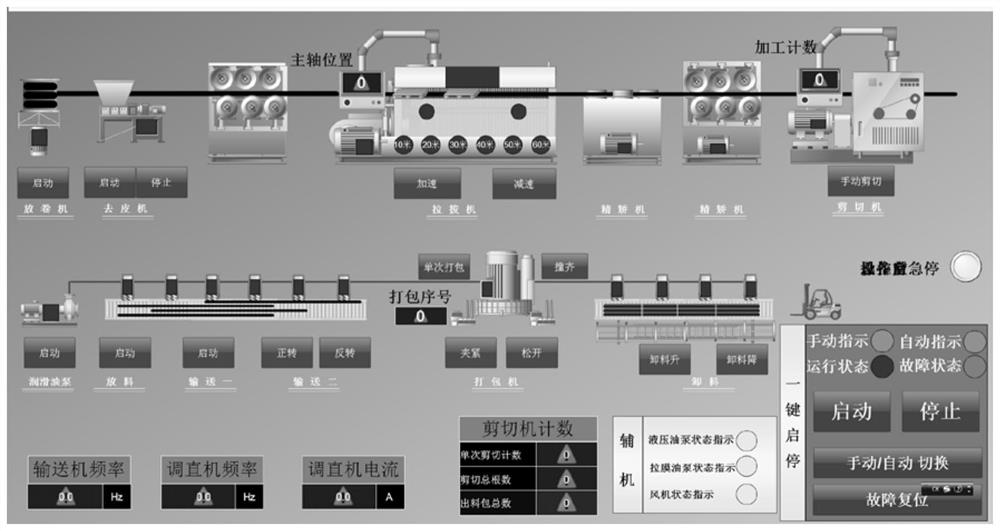

[0043] Intelligent general control process L01: The intelligent general control system is connected to a remote computer server through an optical fiber network cable, and the remote one-key automatic start and stop can be realized through the server. Check the running status and production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com