Environment-friendly energy-saving waterproof material used for building

A waterproof material, energy-saving technology, applied in construction, protection devices, infrastructure engineering and other directions, can solve the problem of concrete leakage that cannot be effectively solved, loss of waterproof performance, etc., to weaken shrinkage stress and reduce water ash ratio, the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

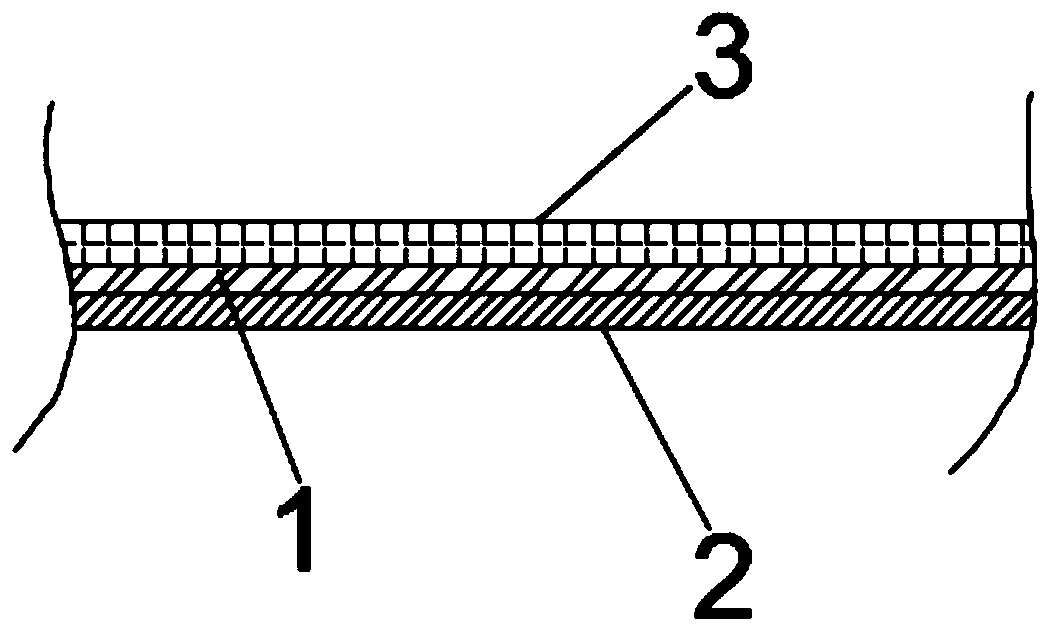

[0021] An environmentally friendly and energy-saving waterproof material for construction, which is made of a mixture of rigid self-waterproof materials and non-woven materials. The rigid self-waterproof material consists of the following components by weight: 255 parts of C35 concrete, 35 parts of fly ash, and calcium formate 6 parts, 3 parts of sodium silicate, 2.5 parts of calcium magnesium carbonate, 2 parts of aluminum chloride, 1.5 parts of iron oxide, 0.5 parts of lignosulfonate water reducer, the preparation method of lignosulfonate water reducer is to Add alkaline solution to the sulfite waste liquid for neutralization reaction, and then remove the carbohydrates through biological fermentation, and finally evaporate and dry it; non-woven materials include hydrophilic fiber nets and water-repellent fiber nets, and the preparation of non-woven materials The method includes the following steps: a hydrophilic fiber web obtained by carding, cross-laid and drafting of coarse-...

Embodiment 2

[0023] An environmentally friendly and energy-saving waterproof material for construction, which is made of a mixture of rigid self-waterproof materials and non-woven materials. The rigid self-waterproof material is composed of the following components by weight: 250 parts of C35 concrete, 30 parts of fly ash, and calcium formate 5 parts, 3 parts of sodium silicate, 2 parts of calcium magnesium carbonate, 2 parts of aluminum chloride, 1 part of iron oxide, 0.5 parts of lignosulfonate water reducing agent; the composition and preparation method of the non-woven material are the same as in Example 1 , The mass ratio of fine denier polyester fiber to low melting point polyester fiber is 15:1, the hydrophilic additives used are a mixture of GH-700 and TF-629C, the concentrations are 1.0% and 1.2% respectively, and the water repellent used The additive is WRS-C35 with a concentration of 8.5%.

Embodiment 3

[0025] An environmentally-friendly and energy-saving waterproof material for construction, which is made of a mixture of rigid self-waterproof materials and non-woven materials. The rigid self-waterproof material is composed of the following components by weight: 260 parts of C35 concrete, 35 parts of fly ash, and calcium formate 6 parts, 3.5 parts of sodium silicate, 3 parts of calcium magnesium carbonate, 2.5 parts of aluminum chloride, 1.5 parts of iron oxide, 1 part of lignosulfonate water reducing agent; the composition and preparation method of the non-woven material are the same as in Example 1 , The mass ratio of fine denier polyester fiber to low melting point polyester fiber is 12:1, the hydrophilic additive used is TF-629C, the concentration is 2.5%, and the water repellent additive used is TG-527 and WRS-C35 The mixture, the concentration is 6.5% and 3.0% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com