Halogen-free flame-retardant thermoplastic elastomer sheath material and preparation method thereof

A thermoplastic elastomer and sheathing material technology, applied in the direction of plastic/resin/wax insulators, insulators, organic insulators, etc., can solve the problems of dense smoke and molten droplets, threats to life and property, and easy decomposition by heat, etc., to improve flow properties, excellent mechanical properties, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

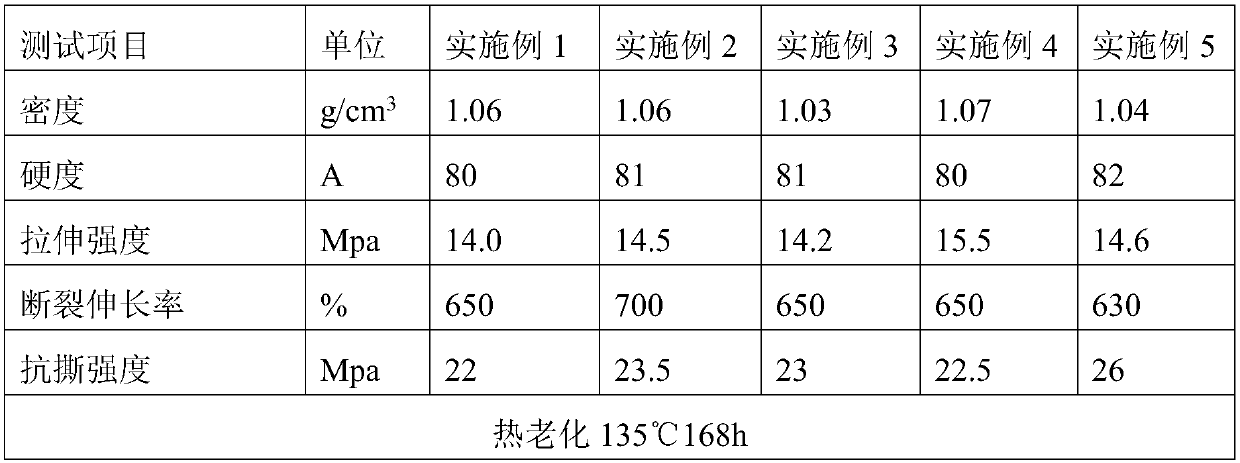

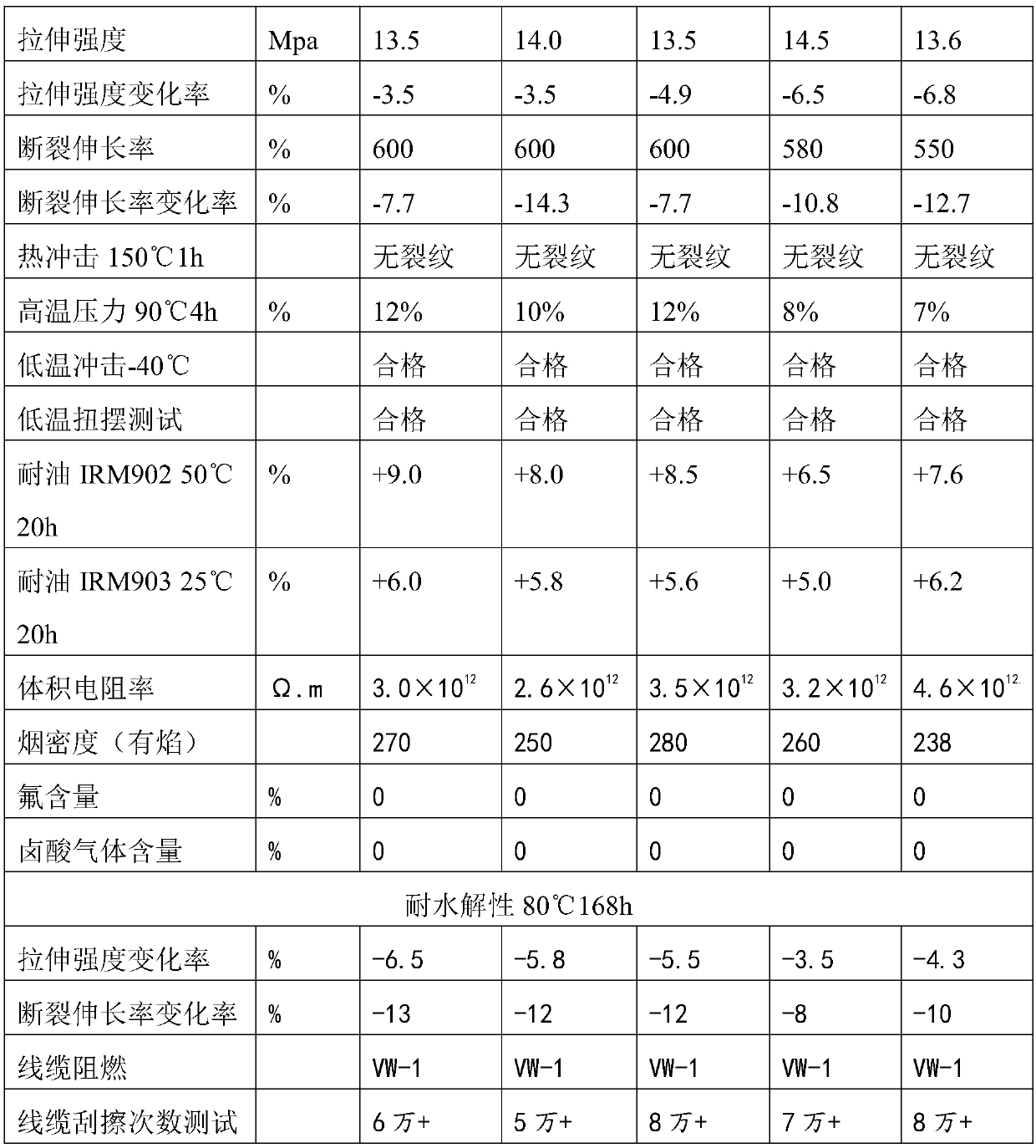

Examples

Embodiment 1

[0052] A preparation method of a halogen-free flame-retardant thermoplastic elastomer sheath material, comprising the following steps:

[0053] (1) Fill 20 parts of SEBS with 20 parts of paraffin-based white oil, and let it stand for 15-20 minutes;

[0054] (2) SEBS processed through step (1) and 10 parts of polypropylene T30S, 10 parts of PP grafted maleic anhydride, 5 parts of EPDM rubber, 5 parts of metallocene polyethylene resin, 20 parts of diethyl thiamine Aluminum phosphonate, 15 parts of triazine, 10 parts of polyphenylene ether resin, 0.4 part of antioxidant 1010, 0.1 part of antioxidant DLTP, 0.5 part of lubricating aid EBS and 0.5 part of PE wax are added to the high-speed mixer for mixing ;

[0055] (3) adding the mixture processed in step (2) into a banbury mixer for banburying;

[0056] (4) passing the mixture mixed in step (3) through a twin-screw extruder, and granulating it under the process condition of 160-200° C. to obtain a halogen-free flame-retardant t...

Embodiment 2

[0058] A preparation method of a halogen-free flame-retardant thermoplastic elastomer sheath material, comprising the following steps:

[0059] (1) Fill 20 parts of SEBS with 20 parts of paraffin-based white oil, and let it stand for 15-20 minutes;

[0060] (2) SEBS processed through step (1) and 5 parts of polypropylene T30S, 5 parts of SEBS grafted maleic anhydride, 2 parts of EPDM rubber, 15 parts of polyolefin elastomer, 10 parts of diethylphosphine Aluminum acid, 10 parts of aluminum hypophosphite, 20 parts of melamine cyanurate, 13 parts of hydrotalcite, 5 parts of polyphenylene ether resin, 0.2 parts of antioxidant 1010, 0.1 part of antioxidant CPL, 1 part of silicone lubricant Add 0.5 parts of lubricant additive EBS to the high-speed mixer for mixing;

[0061] (3) adding the mixture processed in step (2) into a banbury mixer for banburying;

[0062] (4) passing the mixture mixed in step (3) through a twin-screw extruder, and granulating it under the process condition...

Embodiment 3

[0064] A preparation method of a halogen-free flame-retardant thermoplastic elastomer sheath material, comprising the following steps:

[0065] (1) Use 10 parts of paraffin-based white oil to fill 30 parts of SEBS, and let it stand for 15-20 minutes;

[0066] (2) SEBS processed through step (1) and 5 parts of polypropylene T30S, 5 parts of SEBS grafted maleic anhydride, 3 parts of EPDM rubber, 7 parts of polyolefin elastomer, 20 parts of aluminum hypophosphite, 20 parts Parts of melamine cyanurate, 11 parts of hydrotalcite, 5 parts of polyphenylene ether resin, 0.5 part of antioxidant 1010 and 2 parts of lubricating additive silicone are added to the high-speed mixer and mixed;

[0067] (3) adding the mixture processed in step (2) into a banbury mixer for banburying;

[0068] (4) passing the mixture mixed in step (3) through a twin-screw extruder, and granulating it under the process condition of 160-200° C. to obtain a halogen-free flame-retardant thermoplastic elastomer she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com